In order to survive in competition, companies today have to react more and more dynamically and flexibly to customer wishes. This also increases the demands on their machinery. Eckerle Industrie GmbH also had to react flexibly to an order from the automotive industry: The requirements were high: a press for stamped and bent parts that sets new standards in terms of cycle time and continuous part quality. And the whole thing should be as maintenance-free as possible, as well as significantly more compact and cheaper than all other presses on the market.

Within a very short time, an electromechanically driven servo press with a press force of 130 kN was designed and built at the production site in Ottersweier, Baden.

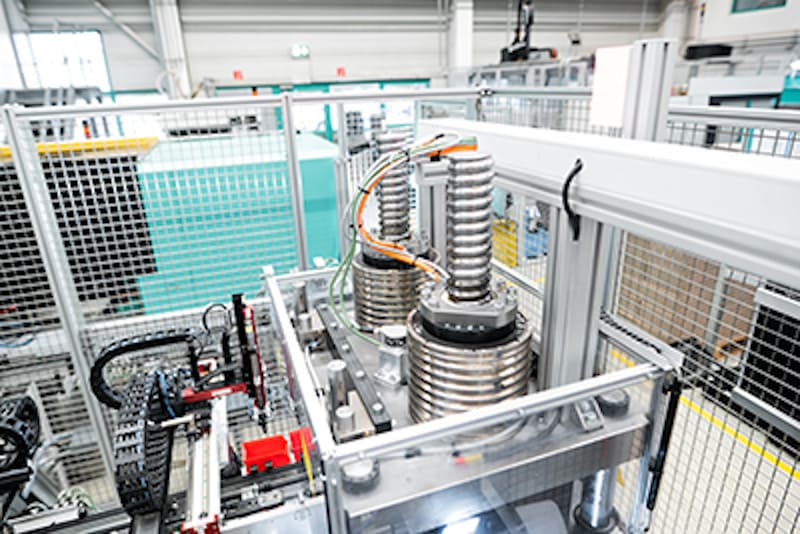

At the heart of the press are two heavy-duty ball screws, each directly driven by a torque motor.

But why an electromechanical drive and then a completely unconventional direct drive? The attractiveness lies, in contrast to purely mechanical drives, in the possibility of adjusting the pressing force and pressing speed individually to the requirements of the machining process. Mr. Deutsch (Automation Team Leader): “During the actual punching process, we press with torque control. This reduces the cutting impact to a minimum. The result is perfect, lasting part quality and minimal tool wear. The rest of the cycle, i.e. bending, closing and opening, we run at the maximum permissible speed for the respective step, thus achieving significantly higher cycle times than with a conventional press. In addition, we monitor the wear of the punching tool with the integrated force measurement and can thus plan the maintenance of the tools.”

Simple and compact – HIWIN drive technology enables new press concept

The hollow shaft rotors of the torque motors sit directly on the nuts to save space and drive the heavy-duty spindles. High-load cross roller bearings provide the bearing support. The result is an extremely compact, virtually maintenance-free drive train for the new servo press.

Since the drive is designed with 2 synchronised servo spindles, even off-centre forces during the pressing process no longer pose any problems. In combination with the own control system, any conceivable drive profile can be implemented with the new drive concept – and thus maximum quality and throughput can be achieved – A new benchmark in press technology.

The advantages at a glance:

- Torques and speeds freely selectable in the press cycle

- Bottom dead centre and stroke freely adjustable

- Tool-friendly cutting impact reduction

- Service stroke for maximum opening and minimum maintenance time

- Up to 130,000N pressing force over the entire stroke

Around the world, around the clock

With more than 3,000 employees, at ten locations, on three continents, in five countries, the Eckerle Group works in the business fields of Automotive, Plastics Technology and Power Tools.

The newly built sophisticated servo press is part of the business field Eckerle Industrie GmbH. In the factory halls in Ottersweier, the production service manager manufactures injection moulded hybrids, i.e. stamped and bent parts which are then directly overmoulded with plastic, for the automotive sector. The parts are used, for example, in brush holders and connectors for all small electric motors, which are now widely used in every car.

However, Eckerle Industrie GmbH is not only a manufacturer, but also a developer and assembler of brush systems, assemblies and EC modules for almost all well-known engine manufacturers in the automotive sector. Further core competences are the integration of electronic components, laser and resistance spot welding and CNC machining. In the field of automation, Eckerle Industrie GmbH is also involved in the development and manufacture of manual assembly equipment and highly automated production lines.

The complete package from HIWIN was convincing

There was only one press supplier on the market that could provide something comparable. However, the costs were simply too high. Therefore, the manufacturing service provider quickly decided to design the machine itself. “With manufacturers of such machines, everything has to be purchased, e.g. the control system and the machine frame. In our case, however, this was not necessary, as we already have a control system in our fully automatic production line and can thus of course also control the press,” reported Mr Deutsch, Automation Team Leader at Eckerle Industrie GmbH.

“Since we knew that HIWIN is a manufacturer of torque motors, we looked around on their homepage. Rather by chance, we saw that in HIWIN we had found a manufacturer who could supply us with the complete package for the drive train of our servo press.”

As part of the process of selecting the right products, Eckerle discussed the envisaged design with the responsible customer advisor from HIWIN: which motor/spindle combination can apply which forces and how are the loads transferred to the machine frame via the cross roller bearings.

Mr Kistner saw it as a great advantage that all scenarios could be calculated together without having to take into account the component conditions of other manufacturers. “HIWIN was the right choice! After all, there are few suppliers on the market where you can get everything from a single source and, above all, with comprehensive advice.”

Hand in hand for an efficient solution

The Eckerle Group developed the servo press in its own design office. Intended for integration into an internal production line, Eckerle Industrie GmbH goes one step further and now also offers the new press generation together with the complete production line to external customers. The Eckerle Group is thus expanding its range of products and services. Here, everything comes from a single source: from design and engineering to production, manufacturing and assembly. Together with HIWIN GmbH, as a specialist for drive technology, a regional and personal contact in the field of mechanical engineering is created.