If one were to ask manufacturers of gearboxes whether demand for precision products will everexceed demand for standard products, they would likely say no. After a 70% increase in precision gearbox shipments from 2009 to 2011, approximately 13% of the 12.5 million gearboxes shipped in 2011 were precision, according to IMS Research’s, recently acquired by IHS (NYSE: IHS), 2012 edition of the Precision Gearboxes and Geared Motors study. Precision gearboxes are typically attached to servo motors in applications where higher torque and high accuracy are required. Although precision gearboxes are not needed in the majority of industrial applications, original equipment manufacturers (OEMs) are investing in precision gearboxes in greater numbers for their low maintenance requirements, high torque densities and precision capabilities. While shipments of precision gearboxes may never outnumber shipments of standard gearboxes, these products are emerging as a viable alternative to standard gearboxes in some applications.

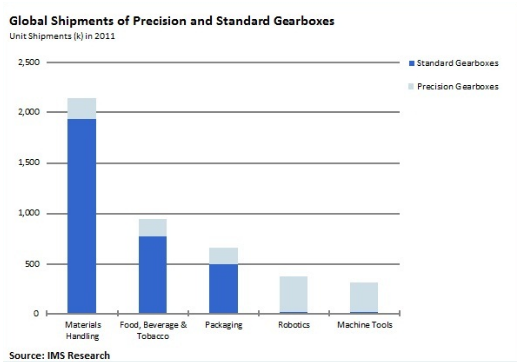

40% of precision gearboxes were used in machine tools and industrial robots in 2011, compared to less than 1% of standard gearboxes attributed to these sectors. In absolute terms, precision gearboxes outnumbered standard gearboxes by more than 5 to 1 in the machine tool and robotics segments in 2011, which shows a clear preference for precision gearboxes over standard gearboxes in these industries. While most machine tools don’t require a gearbox at all, the large number of servo and stepper motors used in this equipment lends itself to being a much larger potential market for precision gearboxes. Many industrial robot manufacturers will often source their gearboxes from precision gearbox suppliers in order to produce industrial robots with higher torque output and a high degree of accuracy.

Industry sectors where precision gearboxes and standard gearboxes tend to come into direct competition with each other include materials handling, packaging and food, beverage & tobacco. In 2011, precision gearboxes used in packaging, materials handling, and food, beverage & tobacco machinery respectively accounted for 25%, 10% and 18% of all gearboxes sold into these sectors. Most applications in these industries don’t require a high degree of precision, which makes it easier for OEMs that are cost conscious to select a standard gearbox. Precision gearbox suppliers have successfully penetrated these industry sectors primarily due to their strong marketing efforts. Most OEMs will carefully consider both the cost and the performance of the gearbox before making a buying decision; however, there are OEMs that will purchase a precision gearbox under the assumption that they require high levels of precision when they actually do not.

Although marketing efforts targeted to grow the precision gearbox market in other industry sectors, such as chemicals and pulp & paper, have been a major source of growth for precision gearbox suppliers in the past, the future outlook for the market for precision gearboxes is not as positive. According to the findings of the Precision Gearboxes and Geared Motors study, weakness in the global economy is expected to adversely affect precision gearbox sales over the next five years, with shipments forecast to grow by an average rate of 3.6% annually from 2011 to 2016. Standard gearbox sales are expected to outperform precision gearbox sales from 2011 to 2016, meaning standard gearboxes will remain the industry standard for the foreseeable future.