Batteries are to have a central role in the future of sustainable energy and mobility. Affordable, high-quality lithium battery packs are needed in diverse kWh ratings to power vehicles ranging from eBikes, drones, and small city cars, to large electric vehicles (EVs), trucks and buses. On the other hand, large, container-sized battery arrays are needed as energy storage for home, commercial, and utility-grade applications to bring stability to tomorrow’s green-powered grids.

Battery Supply and Demand

Through historical investment and planning, Korea and China, have become today’s leading destinations for battery manufacturing. China is the world’s largest maker of lithium-ion batteries, responsible for about 80% of global production . Consulting firm McKinsey & Company expects the total Chinese manufacturing capacity to be about 1220 GWh by 2025.

As western governments have begun to schedule their transition from fossil-fuel mobility to mandate EVs – to meet environmental targets set out in the Paris Agreement – localised battery manufacturing capability is needed. Accordingly, Europe’s capacity for making lithium batteries is increasing as indigenous makers and inward investors gear up to meet demand. Plans have been announced for new factories and expansion of current facilities that could increase Li-ion battery-making capacity to almost 500 GWh by 2025 and could rise to almost 800 GWh by 2030 .

Battery packs for automotive, e-mobility, and general-purpose markets can be built using cylindrical cells in industry-standard sizes such as the 18650 (18mm diameter, 65mm length) form factor, or using flat cells in off-the-shelf or custom sizes. A flat cell can be a prismatic type, typically housed in a square, welded aluminium casing, or a flexible pouch type cell. Whereas cylindrical cells benefit from high strength and durability, flat cells can utilise space more efficiently within the battery pack. Pouch cells, which have no metal enclosure, are the most space efficient and lightweight although extra mechanical support within the battery pack is usually needed.

Building Safe and Affordable Batteries

When building cells of either type, manufacturing begins with preparing and applying active and conductive coatings to electrode sheets and laminating the sheets. Accuracy and repeatability are extremely important to ensure consistency in characteristics such as the coating composition and thickness. Close matching of cell parameters, within the battery, helps ensure safety and longevity.

Speed and efficiency are also critical, particularly when serving markets such as automotive, which is price sensitive. Range anxiety and affordability are two key issues that influence widespread adoption of EVs. The battery contributes substantially to each. Increasing the battery capacity equates to greater driving range, as well as greater vehicle cost.

Cost parity with conventional combustion-engine vehicles is expected by about 2025, and the sale of new combustion-engine vehicles is expected to cease in major western markets and China starting from around 2030. Manufacturers need to reduce the cost of EV batteries. While economies of scale will certainly help, maximising manufacturing productivity is also essential if widespread car ownership is to continue after the combustion-engine ban.

Automation holds the key to achieving the speed and repeatability needed to ensure reliability and economy. Custom automated equipment is often used to handle processes like preparing and applying coatings to electrode sheets, laminating the sheets, slitting into strips, and attaching electrodes by welding.

To build a cylindrical cell, the strips are wound to form the cell core comprising the anode, separator, and cathode, which is then inserted in the cylindrical casing. The casing is grooved to hold the core in place, filled with electrolyte, sealed, and external contacts are attached. Flat cells are produced using a similar sequence, including stacking of the electrode layers, welding the prismatic casing, or forming and sealing he pouch using heat-sealing and vacuum-sealing processes. The cells and battery packs are subjected to electrical testing and automatic X-ray inspection to ensure their performance and integrity.

Flexible Automation

Introducing robots to the manufacturing sequence delivers advantages including fast cycle times and accurate, repeatable operation. Moreover, system integration is accelerated using programmable off-the-shelf robots. Additional advantages include easy scalability, with the flexibility to adapt the factory layout and assembly processes as market demands and customer requirements evolve.

Yamaha has supplied its robots to battery manufacturers throughout China and Korea, the centre of today’s largest and most successful battery-making industries. The robots are performing selected processes in the manufacturing sequence. In fact, more than 3000 SCARA robots are currently deployed in battery manufacturing in China. These are extensively used for loading and unloading the materials, components, and partially completed assemblies as the batteries move from one automated manufacturing process to the next.

Accuracy and high speed are, of course, pre-requisites for these loading and unloading sequences. So, too, are repeatability and reliability; high market demands mean production typically operates 24 hours per day, seven days per week. Major battery brands have chosen Yamaha’s YKXG SCARA robots for these applications (figure 1). Their high-performance beltless drive mechanism, with vertical-shaft motors and directly driven ball screw, enables continuous operation for extended periods, with consistent accuracy. Wasted motion, as well as degradation and the risk of breakage associated with conventional belt-driven alternatives, are also eliminated. The maintenance-free beltless drive also lowers operating costs.

The mainstream adoption of EVs has produced strong market demands for greater driving range. In turn, car makers are specifying battery packs of increasing capacity. The YKXG series has credentials to address this trend, with maximum payload capacity up to 20kg for handling large pouch cells and partially completed battery assemblies. Yamaha’s special R-axis design allows a high moment of inertia that enables the robot to handle a large mass, maximise acceleration and deceleration, and maintain stability, ultimately ensuring a fast cycle time.

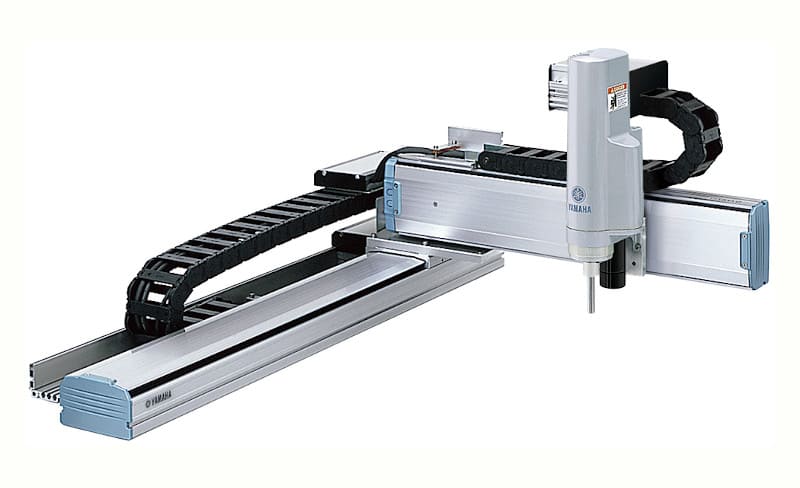

Cartesian robots are also widely used to handle sealing processes in the assembly of square battery cells. Durability and reliability are extremely important to maintain productivity. Yamaha’s cartesian robots (figure 2) contain resolvers for position detection that contain no electronic components or optical elements and therefore cannot become contaminated with grease or dust from the factory. Hence they are extremely reliable and consistently accurate. In addition, the contact guides in the rails of the cartesian robots benefit from a two-point design that minimises friction and prevents alignment fluctuations even when handling high-moment loads.

While single-axis robots are often used within factories of all types, for applications where high-speed transport of items is required, Yamaha’s LCMR200 linear conveyor modules provide high-speed, accurate, and flexible local transport between processes and within assembly cells (figure 3). In battery factories, they are often chosen to transport completed assemblies into X-ray inspection. Because separate LCMR200 modules can be connected and coordinated precisely, installing one on either side of the protective shutter at the entrance to the X-ray machine transports the assemblies into the inspection process and ensure the safety of operators in the vicinity.

Overall, more than 80% of the processes involved in building today’s high-performing lithium batteries are automated, using a combination of traditional factory automation and flexible, programmable robots working together to maximise quality and productivity.

Yamaha, with its extensive experience throughout Asia – including working with leading battery makers and system integrators – is now applying its expertise to assist the expansion of cutting-edge battery manufacturing in Europe.

Conclusion

Choosing robots to automate selected aspects of battery assembly enables manufacturers to build batteries to exacting specifications and within tight cost constraints. Their support for high-speed and high-quality assembly also comes with flexibility and scalability. Robots that have unique features to enhance precision and durability, and are proven in today’s leading battery-making territories, can help ensure a plentiful supply of affordable batteries to meet the growing demands coming from diverse markets worldwide.