A laser photoelectric retro-reflective sensor generation that is redefining the state of the art and setting new benchmarks for performance, reliability, user friendliness and future proofing – that’s the new W12L product family from SICK. Of their numerous highlights, the MultiMode operation concept of the photoelectric proximity sensor really stands out: the user can select between seven different operating modes either on the device or via IO-Link. This versatility in a single sensor ensures maximum flexibility for tackling the wide variety of challenges in object detection.

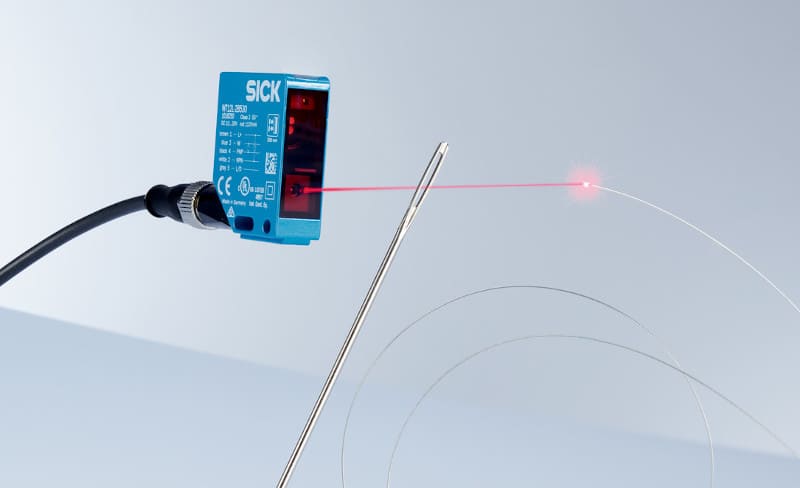

The W12L product family comprises photoelectric retro-reflective sensors with a sensing range up to 12 m, and photoelectric proximity sensors with sensing distances up to 1.2 m. Reliable detection over large distances can just as easily be master as detection tasks in the near range. The extremely precise light spot produced by the class 1 laser light spot of the sensors also allows even filigree objects and features to be detected – even through very small holes or cutouts, depending on the mounting situation. In applications where objects with perforated, structured or uneven surfaces need to be detected, the LineSpot technology with its line-shaped light spot ensures an optimal detection reliability.

Photoelectric proximity sensors with MultiMode: impressive versatility in a single device

A single sensor for a wide variety of requirements and demanding applications – this desire of many users for an all-rounder with maximum flexibility has now been met thanks to the W12L photoelectric proximity sensor with MultiMode functionality. A total of seven different operating modes can be selected. The background suppression, foreground suppression, two-point teach-in, and teach-in of two independent switching points modes ensure an optimal detection reliability in the respective tasks. Window mode can be used to detect objects within a defined detection window.

The ApplicationSelect mode allows the sensor to optionally be configured for a faster response time or a higher sensitivity. It is also possible to output a measured distance value. Thanks to this MultiMode selection, the W12L can be optimally configured for almost any application. The design department therefore always has a suitable sensor in its parts list – and the inventory control department has the right sensor solution in stock at all times. The installation and commissioning staff are always working with the right sensor in the machine, and the service team has a matching replacement sensor on hand at each deployment. That saves time and money.

BluePilot user assistant: the convenient quick start feature

Using the BluePilot operating concept, users are able to start the W12L in a matter of seconds. The sensors can be intuitively configured via a Teach-Turn control element – quickly, precisely and reliably. For the photoelectric retro-reflective sensors, the blue LED display gives the user direct feedback on the optimal alignment, and for the proximity sensors it displays the configured sensing range. Furthermore, during operation the BluePilot activates a visual indicator should the detection quality drop due to contamination or vibration. This allows faults to be corrected and prevented early on, avoiding unplanned system downtime.

Rugged in every respect

SICK also thought of everything with regard to the ruggedness of the W12L. The stable zinc die cast housing masters even the toughest mechanical, chemical and thermal loads. This ensures a high availability and service life even in harsh application environments. From a detection technology standpoint, the geometric filtering of the received signal in the W12L allows the sensor to reliably distinguish between a sensor reflection and ambient light or depolarizing objects, for example safety vests, foil-wrapped packaging and containers, or adhesive parcel tapes. This detection reliability minimizes the risk of erroneous switching and thus process disruptions.

Data provider for diagnostics and monitoring

As a Smart Sensor with IO-Link communication and internal logic, the W12L is able not only to provide a wide variety of status information and data for networked production and control processes but also execute independently defined Smart Tasks. The sensors also deliver comprehensive data for self-diagnostics during operation as well as for predictive and needs-based sensor and system maintenance. The W12L therefore not only offers maximum availability but also long-term investment certainty and a future-proof solution.