In rotary axes that always rotate in the same direction, whatever it is, since, if the number of encoder counts for each turn of the axis is not an integer, the decimal part will be lost and will accumulate in the form of position error.

It is explained in detail below.

What happens on a linear axis?

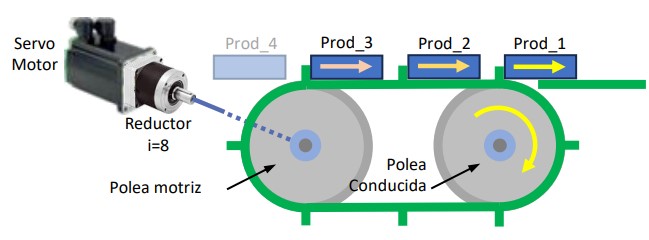

Firstly, we define linear axis as one that has limited its stroke by physical stops, as would be the one in the figure below. This axis causes a linear movement in the carriage driven by a belt and toothed pulley system.The carriage can not move beyond position 0 and 2438 mm.

We calculate how many counts/mm result from this system. 1 Rev/Mot = 1024, 1 Rev/Pulley Drive = 1024 x i; = 1024 x 8 = 8192 C/Rev; 1 Rev/Pulley = 120 * π = 376.99 mm; 8192 / 376.99 = 21.73 Counts/mm

In the table we see several values according to the gear ratio i. For each value of i the number of counts/mm,

the number of counts for the entire stroke and the error due to the decimal part for full stroke are shown.

The column on the right. It indicates the corresponding error in μm, which is totally negligible in general purpose applications. Error is absolute so; it can not be not cumulative.

Therefore, the value of the gear ratio does not affect anything other than the number of counts/unit at all and does not accumulate because the axis has limited stroke. The bottom axis, is another example, may appear rotary, but it is still linear since it has mechanical position limits. The table also shows the absolute error, in this case in Arcmin, due to units are degrees.

Conclusions on a linear axis.

- It does not matter if the number of counts/unit is not integer, since the error is not cumulative, it is an absolute error of negligible value for general purpose applications.

- The counts/unit value should be at least 50, it will depend on the resolution of the encoder and the gear box ratio.

- It is usually easier to design the mechanical transmission for linear axles than for rotary ones, which we will see below.

- In case of applications that require a high precision, linear scales of high resolution and precision are used, so the reduction ratios matter even less for precision purposes.

What happens on a rotary axis.

Suppose a mechanical system like the one shown in the following sketch:

In this application it is about making an advance every time a product arrives, so the axis will always rotate in the same direction. As long as a full turn of the drive pulley corresponds to an exact number of encoder

counts, there will be no problem and the system will be able to operate 24/7/360 without any error accumulating. The units of measurement in the example are steps and the system has 8 steps.

In the event that the gear ratio causes a turn of the drive pulley not to correspond to an exact number of encoder counts, that decimal part that physically does not exist will accumulate in the form of an error and the position of the axis will be out of phase.

The table below shows an analysis of the accumulation of the error, considering a production speed of 80 cycles per minute, for each of the gear ratios and with an encoder of 1024 counts /Rev.

It is noted that, if the reduction ratio is exact, the number of counts / Rev. logically will also be exact. It may even be the case that, with a non-exact relationship, but with “limited” decimals such as 3.5 or 4.5 the number of counts / Rev, it comes out exact and therefore there is no problem of accumulation of error.

Conclusions on a rotary axis.

- A rotary axis always moves in the same direction and its position usually goes from 0 to a value called period, which is usually 360 degrees, but it can be a step, a product, or any other user unit.

- If for any reason the number of encoder counts per axis turn is not accurate, since the decimal part does not physically exist, it will accumulate in the form of an error.

- The error may be minimal, but it grows continuously and after hours or days will cause a machine stoppage.

- To avoid this problem, you must design the axis so that one turn assumes an exact number of encoder counts.

- In many cases this is not considered and then it is when the programmer has to fix the mechanical design flaws by software, with a sensor that indicates the zero position of the axis and redefining its position on the fly every so often operating time.

- It’s important to eliminate problems at the root and not have to do software magic.