MVTec Software GmbH,will launch version 5.6 of MVTec MERLIC on October 16, 2024. MERLIC is an intuitive no-code software that enables users with little or no experience in industrial image processing to achieve immediate success.

The software also features strong integration into various industrial manufacturing processes. “We will continue to enhance MERLIC’s connectivity in the new version. Customer feedback has encouraged us to continue on this path and make MERLIC as easy as possible to integrate into various operational environments.” “Of course, version 5.6 also includes new image processing methods and improved usability,” explains Ulf Schulmeyer, Product Manager MERLIC at MVTec. With regard to improved connectivity, version 5.6 includes a plug-in for Siemens SIMATIC S7 PLCs. In addition, the existing plug-in for the REST API has been extended with new functions for direct access to image results. New image processing methods include the ability to control the quality of 2D data codes as well as surface reconstruction with photometric stereo, the latter of which is also used for quality control. Customers can also look forward to the expansion of AI-based deep learning applications.

Communicator Plugin Siemens S7

The new version of MERLIC includes a plugin for communicating with Siemens SIMATIC S7 PLCs. Direct access to the widely used Siemens PLCs further improves MERLIC’s connectivity. For customers, the plugin offers improved usability as well as faster and more direct integration into the operational environment.

REST Plugin

The REST plugin is available from MERLIC 5.4 onwards. This interface opens the door to the world of REST API web services. With the new MERLIC version, images can now also be accessed via the interface. This is useful, for example, if you want to embed images from MERLIC directly into an HTML website, allowing users to control and monitor production processes. This means that customers can integrate images from the REST API directly into their applications. In addition, the expanded image memory makes it possible to retrieve images asynchronously from MERLIC via plugins.

New Machine Vision Tools

In MERLIC 5.6, several methods that were previously available for testing have been converted into completely new tools. These tools are “Counting with Deep Learning”, “Image Segmentation with Pixel Accuracy” and “Color Detection”. “Deep Learning Counting” (also known as Deep Counting) allows for fast and reliable counting of large numbers of objects with low training effort. This feature has many applications, including completeness checks. “Pixel-Accurate Segment Images” allows for pixel-accurate localization of learned error classes, allowing users to solve inspection tasks that were previously impossible to solve at all or required significant programming effort. The “Detect Color” feature allows users to reliably recognize colors under a variety of conditions. Furthermore, the results can be further improved by suitable parameter settings. This process particularly contributes to quality assurance, for example for inspection tasks or the selection of suitable components.

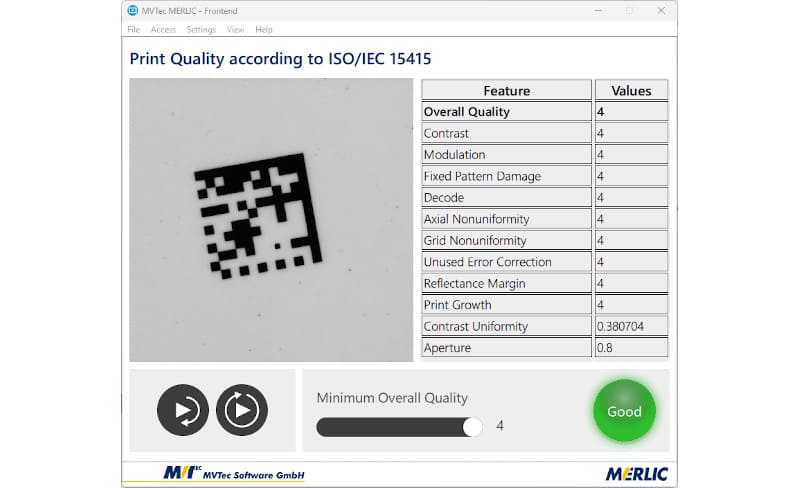

Print quality of 2D data codes

Quality control of 2D data codes is particularly important for the production industry. A new procedure in MERLIC 5.6 not only reads the code, but also evaluates its print quality. The print quality of the code is determined in accordance with the AIM DPM-1-2006 and ISO/IEC 15415 standards. The new method speeds up the process of checking the print quality of product labels, which is very important for many companies.

Reconstructing surfaces with photometric stereo

Photometric stereo is a technique in industrial image processing that is used to reconstruct the 3D surface structure of an object. This approach is often used to detect defects. The corresponding function “Reconstructing surfaces with photometric stereo” is available in MERLIC initially as a concept tool. The lighting required for this technology can be easily controlled within MERLIC via GenICam. Simplified image source parameterization

Image capture parameterization allows you to easily switch between different predefined camera parameterizations. This leads to increased usability and time savings, and allows MERLIC’s machine vision applications (so-called MVApps) to run with specific camera settings, thus enabling new use cases.

Image region optimization in “global context anomaly detection”

Furthermore, the deep learning-based technique “global context anomaly detection” has been further developed for MERLIC 5.6. This technology “understands” the logical content of an image and detects new variants of anomalies. You can now define a specific image region. Image content outside this range is ignored, resulting in more robust results.