In automated environments, quality control relies on the continuous measurement and monitoring of test data. Engineers need systems that ensure accurate and safe positioning of test parts, essential for reliable and accurate measurement results.

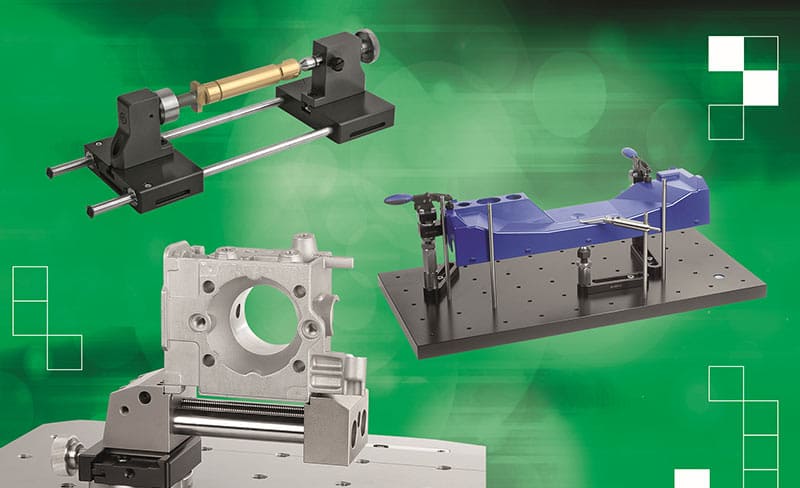

To solve this problem, Norelem has introduced an innovative new modular clamping system (34005) line for metrology. These new clamping systems offer engineers and technicians great benefits as they offer flexible modular solutions that adapt to the evolving needs of different industries.

Unlike traditional clamping technologies that require large forces, norelem’s systems are designed to require minimal clamping forces, making them ideal for fast and efficient assembly of even the most complex structures. For engineers, this means faster workflows, less fatigue and fewer errors, leading to increased productivity and greater measurement accuracy. The system’s flexibility extends to a wide range of applications, from marking and laser technology to handling and the food industry, ensuring that it meets the diverse requirements of modern manufacturing.

Norelem CEO Marcus Schneck comments: “Even if additional steps are required, the modular design ensures that engineers are always one step ahead, as the system can easily adapt to these specific requirements.”

“At Norelem, we offer solutions that support a wide range of measurement techniques, from tactile measurements with CMMs to optical metrology and surface and contour measurements. Our systems are designed to give engineers the flexibility they need in every scenario.”

The modularity of Norelem’s clamping systems is further enhanced by a large number of combinable standard components, such as basic holders, assembly modules, operating units and clamping elements. This means that engineers can quickly put together new configurations or reconfigure existing setups with minimal interruptions.

The system is resource- and cost-efficient, saving time and materials. A uniform interface also simplifies the measurement process and reduces the risk of user error, as all measurement points are accessible in a single setup.

Schneck added: “We simplified the assembly and reconfiguration process by developing clamping part sets specifically designed for CMMs, surface and contour measurement and optical measurement systems. These kits contain a predefined selection of foundations, mounting and clamping parts, allowing users to easily create both simple and complex setups.”

Norelem clamping systems offer a long service life due to their wear-resistant and maintenance-free design, making them ideal for reuse without recalibration. In addition, the introduction of a new quick-change pallet system allows external changeover of optical measurement equipment, further reducing downtime and increasing productivity.