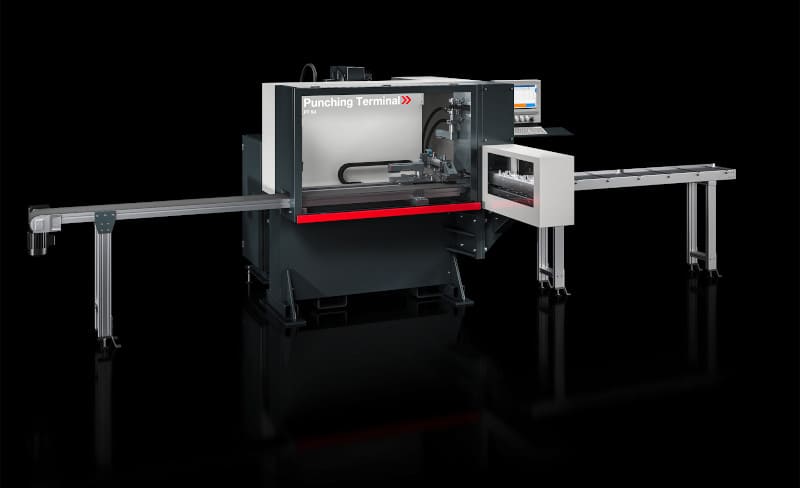

Getting started with automated busbar processing is often a big hurdle for smaller switchgear manufacturers, but the new PT S4 punching terminal from Rittal Automation Systems makes it easy to get started – even if you only process a small amount of copper per year. Despite its compact design, the new machine features three exchange tools and one tool for cutting busbars to length, as well as a connection to the RiPanel Processing Center for digitalized order processing. Another advantage for users is the coordinated and consistent interaction of Eplan’s planning and building tools across the entire plant engineering value chain, from planning to machine operation.

Conductor rails are a large growth market and demand is constantly increasing due to several factors. Electrical energy is becoming more important in all sectors, from electrical energy generated directly by photovoltaics and wind turbines to e-mobility. Digitalization itself also consumes large amounts of energy, due to the increase in large data centers. In addition, major economies such as the United States have changed their technical regulations, which means a switch from cables to busbars in all types of enclosures.

The ever-increasing flow of energy that needs to be distributed means that more busbars will be needed. The new PT S4 punching terminal also offers smaller switchgear manufacturers the opportunity to enter this future market and expand their customer base independently from suppliers.

Machining of copper and aluminium

The basic version of the Punching Terminal PT S4 processes flat copper, but the system can also be designed to process aluminium if needed. The PT S4 processes bars with a thickness of 3 to 16 millimetres and a width of 15 to 127 millimetres.

Four tool stations are installed to fit standard tools with a quick-change system, including a separation unit. Thanks to the strong tool springs and the resulting high retraction forces, even thick copper bars can be punched extremely cleanly so that no reworking is needed.

Digitisation for efficient punching

The interaction of Eplan engineering tools across the value chain, from planning to machine operation, is particularly beneficial. The Punching Terminal PT S4 is supplied with data from the digital software solutions from Eplan, such as the Eplan Pro Panel with the Eplan Copper module or other applications. The machining centre reads the geometry and then independently punches the holes and recesses desired into the blanks supplied. The system can also be integrated into the Rittal RiPanel Processing Center software. Then, orders and processes can be automatically distributed and digitally monitored. Furthermore, the networking of punching and bending machines with a shared database enables work on multiple machines. Programming can be performed directly on the machine and from the office workstation.

With the Punching Terminal PT S4, Rittal Automation Systems also offers smaller companies working with just a few tonnes of copper busbars a year the chance to get involved in automated busbar processing. In such applications, the new, compact machine will pay for itself in two to three years.