Baumer encoders from the “Hübner-Berlin” brand have set the standard in HeavyDuty applications for 70 years. With the new HOG800 series, Baumer introduces the next generation of these successful encoders, offering improved resistance to corrosion, shaft currents, overvoltage, and mechanical stress. That’s novel: Baumer has integrated the intelligent features of its extensive industrial encoder range to cater to HeavyDuty applications. Certain smart functions include intelligent adjustment of resolution, output level, and rotation direction, integrated within the Baumer Sensor Suite. Additional features for tracking sensor status, temperature, and operational duration are now accessible.

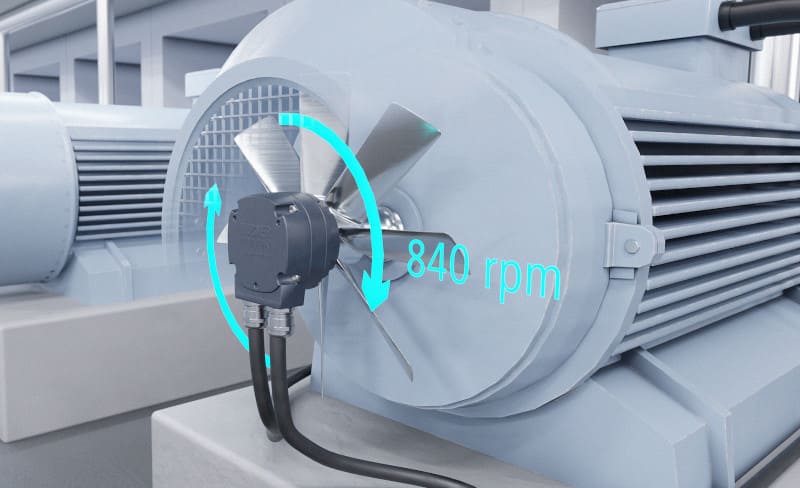

The HOG800 series offers high-performance encoders designed for challenging applications that require the utmost reliability and accuracy. These exceptionally sturdy HeavyDuty encoders are ideal for use in asynchronous motors, cranes, hoists, and cold rolling mills. Featuring a compact design and adaptable protection, the HOG800 series is an ideal option for speed detection in asynchronous motors operating in challenging environments.

Remarkable durability and intelligent extra features

The built-in intelligent features of the HOG800 series make commissioning and maintenance easier: The Baumer Sensor Suite enables straightforward reading and labeling of electronic nameplates, as well as the parameterization of resolution and output circuit, along with status information inquiries. Ongoing surveillance of sensor performance, output, temperature, and duty cycle detects any possible malfunction at an early stage.

The HOG800 series also stands out with its compact size, featuring housings that are just 84 mm wide. The sealed and easy-to-use design enables convenient installation in the field, even under challenging conditions. Another advantage is the enclosed sensing unit, which is safeguarded against dirt and dust during terminal box installation with an IP40 rating. Additionally, the terminal box featuring plug-in terminals guarantees straightforward and secure wiring. The cables within the terminal box are kept apart from the shaft to avoid being tangled or harmed.

The products of the HOG800 series are HOG840, HOG860, HOG870 and HOG890:

HOG840 is the cost-efficient variant particularly designed for wind turbines and machinery. It features high C4 corrosion protection according to DIN EN ISO 12944, is capable of operating temperatures ranging from -30 to 85 °C and cable lengths of up to 200 meters (HTL-P).

HOG860 has been designed for demanding applications at machines and asynchronous drives. Unlike HOG840, HOG860 features extended electrical protection, specialized parameterization options, status monitoring as well as extended temperature range from -40 to 100 °C. And, HOG860 features CX corrosion protection for particular resistance to corrosive environments.

HOG870 is a redundant HeavyDuty encoder with redundant sensing and evaluation with 6 additional outputs. This encoder is designed for safety-relevant applications.

Further to incremental signals, HOG890 features three digital switches for long-distance transmission of standstill, speed, direction and status information to the control unit.

The HOG800 series from Baumer sets new standards for HeavyDuty encoders. With further enhanced robustness, maximum user-friendliness and smart functions these HeavyDuty encoders ensure reliable operation and simplified commissioning in demanding applications.