In most cars and light utility vehicles, vacuum brake servos (or brake boosters) aid drivers by decreasing the braking effort required. The vacuum pump is a critical component of the system, and even the smallest defect does not meet the stringent quality requirements for manufacturing these systems. Zeltwanger Automation GmbH in Dußlingen, near Tübingen, Germany, assembles and tests 400,000 pumps annually and assigns each its own data record with measured values. The data is contained in a laser-etched Data Matrix code that is placed on each product and read by the Cognex DataMan® barcode reader. The barcode reader decodes the information and transmits the data to the factory network, providing total traceability of the parts.

Testing assures braking force

It takes 40 seconds for a vacuum pump to complete a full rotation on the round stepping table of the Zeltwanger assembly and test cell. The test cell automatically screws on the cover and tests the seal of the pump. After confirmation that all seals have been assembled and all sealing rings are intact, the pump is connected to a servo-controlled drive for testing. The vacuum pump is tested with various speed ranges with measurements of torque and pressure and given a hydraulic test of oil pressure and a flow test with the oil at operating temperature. If all steps of the test are passed, a laser marking system places a Data Matrix code with the measured values and the serial number and the date of manufacture in plain text.

Data adds force to statements

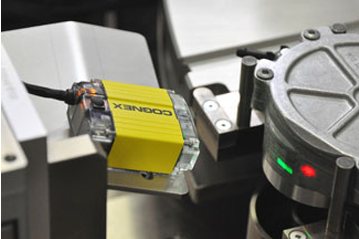

In the next step, the DataMan barcode reader scans the newly etched Data Matrix code and confirms a 100% reliable readout result. It outputs the measured values as a whole. This step ensures that measured values can be accurately associated with each product for its lifecycle.

The DataMan barcode reader ensures all of the required data from the preceding test steps is contained in the code and is readable. If all of the information is recognized and the part passes, the vacuum pump will be released to the next stage. If the information is inaccurate, the parts will be rejected and an adhesive label is applied by the operator to indicate it requires subsequent correction.

Performance that sets a standard

Including the testing values in the Data Matrix code and ensuring it is readable and stored for traceability purposes provides Zeltwanger Automation GmbH with great confidence and process reliability. The DataMan barcode reader provides lighting, imager and processor in a single small, compact housing with industrial connectivity. Even in constricted spaces with demanding ambient conditions, the DataMan barcode reader delivers high, accurate read rates of the 2-D DPM (Direct Part Mark) Data Matrix codes.

In the final process step, Zeltwanger’s new assembly and test cell delivers the data contained on the Data Matrix codes to a gateway PC equipped with two network cards. By doing this, the cell operation is separated from the customer network. If the event of error messages, Zeltwanger’s service staff can intervene directly via remote server control without having to pass through the customer’s system and minimize downtime.

[info]http://www.cognex.com/ [/info]