Datalogic announce the new STS320™, an imager system based on the new powerful Matrix™ 320 reader. The array of readers embeds a superior 2MP sensor, combined with an advanced multicore platform.

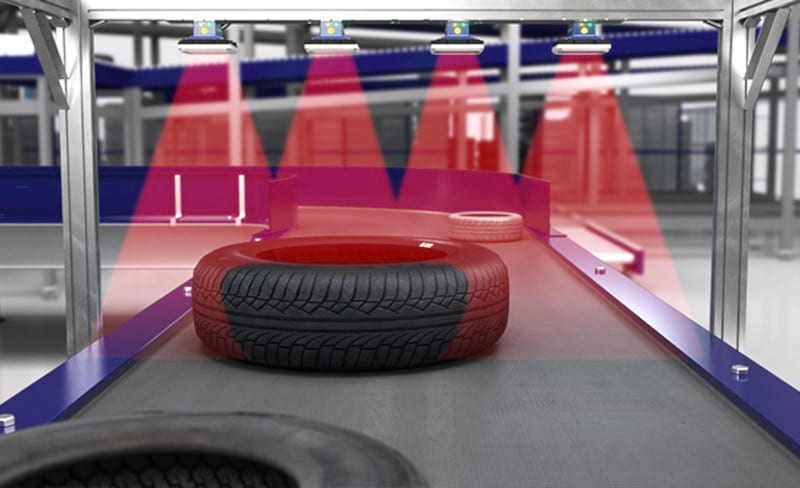

The STS320 provides tire manufacturers with a complete traceability solution for all applications along the supply chain. It uniquely takes customers’ reading performance levels over 99.9%. It leverages an extra-large Field of View (up to 1,250 mm / 49’’) and a high Depth of Field even on high resolution code to cover the full application range even on very large conveyor. The STS320 capability to work with conveyor speeds up to 1.5m/s and with reduced minimum gap among tires significantly increases productivity.

To save customer’s precious time and money, the STS320 is an out-of-the-box, pre-assembled, pre-configured and factory-validated solution. The device is designed to be very quickly and smoothly installed. As a matter of fact, a single operator can install the system in few minutes.

Customers can easily setup, use and monitor the readers through the DL.CODE software and a complete suite of remote diagnostics. The new generation of web interface enables the web Device Discovery and the web image Mosaic view to monitor all the readers for a flexible and intuitive diagnostic. The STS320 can work with Datalogic WebSentinel™ Plus, an advanced monitor and information collector which offers Real-Time Performance at a glance with key features, diagnostics, and insights to end-users.

Gathering information for process quality analysis has never been easier. The run time for Unreadable Code detection will catch and flag any damaged code. A live high speed FTP image transfer allows optimized post-processing performance analysis and diagnostics to increase production throughput.

Customers benefit from a drastic TCO reduction: this highly rugged device ensures undisputed long-term reliability and life cycle, and minimum wear and tear. It is the most cost-effective solution on the market for the full range of tire sorting applications.

The STS320 can efficiently work even in the harshest industrial environments, including during the curing process. It is Sulphur gas resistant, according to ISO EN 60068-2-43, and has IP67 and IP65 rating. The device has a great operating temperature range: from -10° to 50° C, and a storage temperature from -20° to 50° C.