The inductive sensors include integrated measured value filters with five pre-set filters, which significantly simplifies the evaluation process through the parameterization of the primary sensor function via the IO-Link interface and reduces the variant diversity. Applications with very high demands for resolution or speed can be resolved with a single sensor type. This benefits the users of inductive sensors, who are faced with increasing complexity when choosing a suitable sensor and thus require a great deal of time to develop a good solution.

Particularly fast or with micrometer precision? Diverse application requirements can be resolved very reliably with one and the same sensor

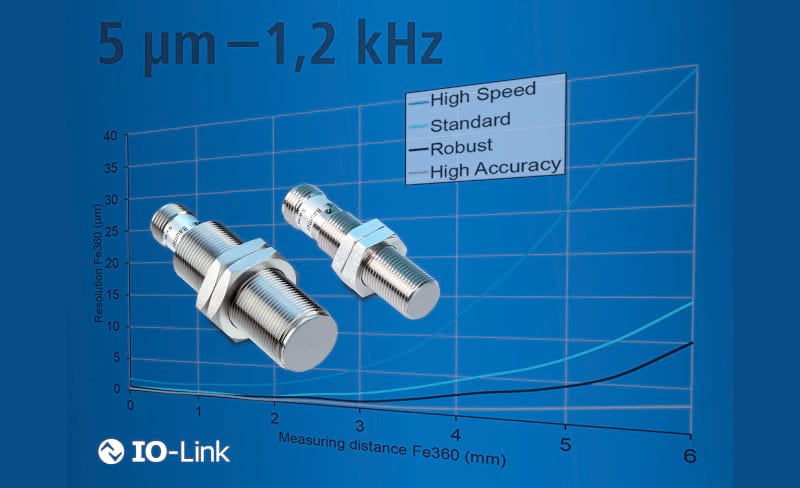

Next to the standard setting, the measured value filters offer four additional optimization options: high speed, high accuracy, robust, and high pass. The high speed mode is especially reliable for tasks involving fast moving parts with a speed of up to 1.2 kHz. However, high speed is detrimental to the precision of the measured values, which is still surprisingly high at up to 10 micrometers at half the measuring distance – precision is a special characteristic of the inductive distance sensors from Baumer.

However, if highest precision is required instead of speed, for example, for the detection of material expansions ranging from three to five micrometers, then high accuracy is the correct choice. Selecting the robust filter allows applications to be handled even more reliably than in the standard mode. With a speed of up to 100 Hz, the detection is still sufficient for many applications. With the integrated high-pass filter, either frequencies under 300 Hz can be hidden or frequency peaks above 300 Hz can be detected during frequency measurement.

These integrated setting options are unique in the inductive sensors market, and Baumer additionally complements them with the option of parameterizing the output scale (input scale). Prevailing installation tolerances due to the environmental and application-based pre-damping depending on the type of metal can thus be very simply compensated via the software. Manual setting of the sensor on site is no longer required due to the new options that are made available by the IO-Link interface. This facilitates and significantly reduces the time required for commissioning the sensor.

The Baumer portfolio of inductive sensors with measured value filters and individual output scales that are parameterizable via the standardized IO-Link interface currently includes cylinder sizes from 6 to 30 mm.