Metal-forming machines rarely enter a fourth decade of service. But when Royal Vendors (Kearneysville, WV www.royalvendors.com), a manufacturer and remanufacturer of cold drink vending equipment, faced declining performance from its key two-axis metal former, it was faced with a crucial decision: refurbish or replace.

The metal former is used to roll, stamp, and cut a complete variety of parts for Royal Vendors products, turning long rolls of sheet metal, up to three feet wide, into the components involved in dispensing cold drinks. It’s involved in manufacturing virtually every Royal Vendors product. Because Royal Vendors is the global leader in the design and manufacture of highquality cold-drink vending machines, that covers a variety of products.

Ultimately, they decided on a drive and control systems overhaul, instead of replacement. “Studies showed that was the most cost-effective option,” says Scott VanMetre, Plant Engineer, Royal Vendors. “Plus, there were the issues of minimizing downtime and disruption involved in replacing the machine, and it’s familiar to our staff.” A rugged and powerful machine, the metal former is so large (35 by 75 feet) that removing it would impact other aspects of the company’s operations.

The metal former has some impressive capabilities. The versatile, two-axis machine features a leveler (one axis) that feeds 8- to 10-ton rolls of material into a straightener (the second axis). The straightener then feeds the material to a preset distance based on a material encoder. The material is then cut to specifications. Two photo eyes determine the distance required for loop control. The machine generates impressive throughput and usually begins the first step in creating complex parts by producing slices of metal that are finished in other plant areas. That helps Royal Vendors create up to 500 different vending machine components, from machine components measured in linear feet to coin return parts measured in Inches.

However, with aging DC motors and outdated analog controls, “old reliable” wasn’t providing the accuracy and precision Royal Vendors needed for creating new generations of complex vending machines. The two axes required two separate inputs, reducing efficiency and consuming energy that drove up electricity costs.

Fortunately, Royal Vendors had the ideal partners for a machine upgrade: Livingston and Haven (Charlotte, NC www.lhtech.com), an Industrial Automation Distributor with whom they’d worked in the past, and Bosch Rexroth (Charlotte, NC www.boschrexroth-us.com) that could supply drive and control components, as well as quality hydraulics components. The partnership could deliver quality work and high performance parts on a tight deadline (the machine could be down for no more than two weeks). Royal Vendors also knew that Rexroth along with L&H would supply engineering and technical support for tasks like operator training and reprogramming machine PLCs.

The L&H team began by assessing the aging machine’s needs. “You could say that the body was still strong and powerful, but the machine needed a new brain and nervous system,” says John Gaddum, L&H Automation and Regional Automation Sales Manager. “We determined that Rexroth controls and AC motors were the best choice.” Royal Vendors, L&H and Rexroth agreed on a retrofit plan to give the metal former greater accuracy, two-axis control from a single input and more reliability with energy and space savings—while preserving throughput and versatility.

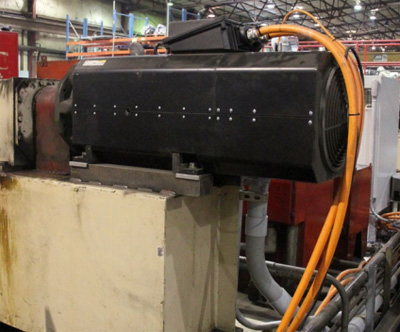

The plan was to replace the antiquated analog controls and DC motors with a combination of intelligent modular Rexroth IndraDrive M servo drives and high-power density, high-precision IndraDyn MAD air-cooled AC motors with high-resolution encoder systems. The operator interface would be set up via a Rexroth IndraControl VCP08 HMI and SERCOS III communication protocol. That would give the machine a performance makeover: precise digital controls, reliable asynchronous motors, lower-voltage motor signaling (24 V instead of 110 V) and an intuitive interface.

The machine operator would have the ability to initiate operations (e.g., roll feed operation) from a single source of input (HMI), including quick machine stop and start. Computer commands would make changes in operating parameters (e.g., dimensions for forming) much easier. Designed specifically for multi-axis applications, Rexroth’s modular IndraDrive M features compact inverters and power supplies with integrated main connections. A closed-loop DC bus would provide the necessary inverter voltage. The IndraDrive M would save space and use less energy. In fact, in combination with new asynchronous motors with regenerative power capability, the new drive could return electrical power, formerly wasted, to the system to reduce energy costs.

The new AC motors would be Rexroth IndraDyn A (MAD 225) fan-cooled units,the most powerful of Rexroth’s IndraDyn A line. The MAD 225 features an output of over 137 kW with 640 Nm of torque. Rugged and reliable, these new motors also offer great accuracy and repeatability.

Rexroth would also provide upgraded reprogramming for the machine’s old, custom controls, putting modern communications protocols in the operator’s hands. The reprogramming included resetting parameters and replacement of the old CCS unit controller with a multi-axis SMC motion control platform—Rexroth’s first installation of SMC with both IndraDrive and MAD motors.

Integrating these components would give Royal Vendors operators more options in how vending machine parts are produced. In automatic mode, a feed angle signal would tell the system to begin feeding the material, and determine the feed angle. Both axes would then work together for high throughput. In manual mode, the operator could run the axes either separately or together, with the leveler in sync with the straightener to allow material feeding for setup. Run separately, each axis could cut parts to a different set of dimensions. At startup of a new steel coil, the operator could run the leveler axis only, to feed the material. Then, once a good first piece (in spec) was created, the operator could then run the system in full automatic mode with both axes in sequence. At the end of each coil, the operator would run the shear side/measuring axis to finish the coil.

The two axes could also be run at separate speeds, the leveler at a constant speed (adjusted by loop control) while the straightener made a complete stop for each cut of the shear. This would save considerable energy by not requiring the leveler to stop and start for each cycle of the straightener and shear.It was the perfect solution—but the retrofit challenge became tougher when the team suddenly learned it would have just seven days to complete the job.

They needed only five.

Within that time, Royal Vendors was experiencing the increased reliability and accuracy of their rejuvenated metal former, with even greater throughput. But the advantages of the new machine go beyond greater precision. Royal Vendors now has the flexibility to run the machine axes separately or together, as the situation demands. The operator has more complete control and diagnostics which leads to greater safety as well, thanks to the upgraded HMI(Human Machine Interface). For instance, instead of having to open a control panel for troubleshooting, the operator now receives error or warning messages and can make changes directly from their workstation. The machine is easier and faster to stop, reducing the risk of injury. When Royal Vendors needs to implement more frequent changes from coil to coil to handle short product runs, the new machine’s efficiency minimizes downtime and keeps throughput high.

The new machine is also much “leaner” than the old. It’s more energy efficient, thanks to regenerative capabilities, and rarely requires electrical maintenance calls. Its accuracy also means less wasted material, and fewer components out-of-spec. Replacement parts and knowledgeable support, are no longer hard to find, so a collection of spares won’t be needed on-site.

Best of all, the machine is easier to adjust, troubleshoot and maintain. “You’re changing software commands instead of having to move physical parts and wires,” VanMetre says. “It’s equally easy to change from one type of job to another.” On the rare occasions when parts are out-of-spec, the machine’s improved diagnostics make it easy to find out why. Peace of mind is truly one of the “new old” machine’s most important benefits.

The irony of the retrofit project was that the L&H and Rexroth team delivered exactly the same benefits that customers get from a Royal Vendors vending machine: a greater variety of easily-selected options, predictable results and quality products delivered quickly and easily. For Royal Vendors, the retrofit process and operation of the upgraded metal forming machine has truly been a refreshing experience.

Challenge:

Upgrade an aging two-axis metal forming machine to increase precision and accuracy, add greater control and flexibility, and make troubleshooting and adjustment easier—with minimal downtime during the upgrade.

Rexroth Solution:

• IndraDrive M drive

• IndraDyn A series MAD motors with regenerative capabilities

• SMC software

• IndraControl VCP08 control HMI

Results:

• Greater precision and accuracy with increased throughput

• More complete operator control (two axes can be operated separately or together)

• Reduced wasted material

• Reduced energy usage and costs

• Easier to obtain parts for maintenance, adjustments or further upgrades

• Easier troubleshooting, maintenance and reconfiguration for various jobs

• Predictable, repeatable output

[info] www.boschrexroth.com [/info]