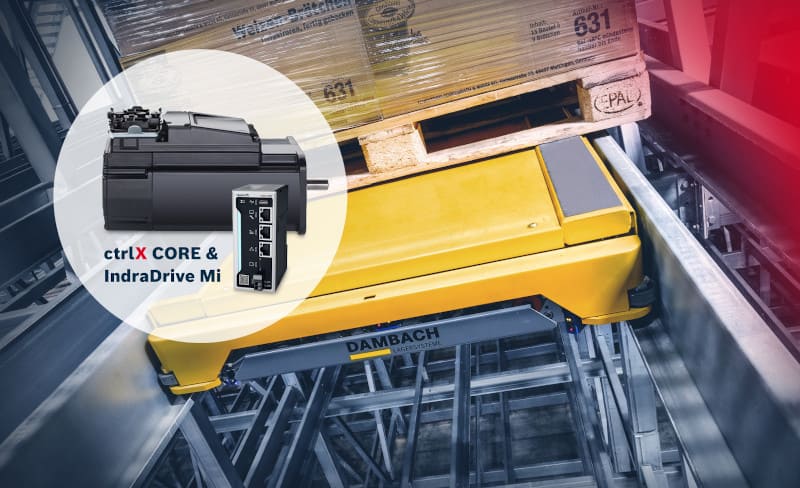

Intralogistics is changing: In many areas, mobile and flexible assistants are replacing rigid transport units or manual processes. The company DAMBACH Lagersysteme is bringing the benefits of automation to the warehouse. The DAMBACH COMPACT SHUTTLE allows pallets in high-bay warehouses to be stored and retrieved even more efficiently. At LogiMAT 2023 (Hall 6, booth D31), Bosch Rexroth will demonstrate how the solution is controlled by the space-saving and high-performance control system ctrlX CORE and how its strengths can thus be optimally exploited.

High-bay warehouses offer great potential when it comes to storage space and handling capacity. With flexible and automated conveyor technology, these factors can be exploited to the maximum compared to manually operated systems. DAMBACH therefore develops automated storage systems which meet both current and future demands for versatility and speed in industry and commerce.

1,500 kilograms pallets stored and retrieved in next to no time

The DAMBACH COMPACT SHUTTLE makes it possible to store and retrieve large load carriers, e.g. EUR pallets, in high-bay warehouse channels. It is extremely quick too: It takes less than two seconds to pick up or put down a load. Up to 1,500 kilograms can be picked up and transported reliably and quickly. Together with storage and retrieval machines or the transport vehicle “CARRIER”, pallets can be stored in a particularly compact manner with multi-depth storage. The storage channels are equipped with runner profiles on which the shuttle moves. It travels along the runner profile to a specific storage area and then picks up or puts down a pallet. Optimized positioning of the shuttle further increases the storage density of the pallets on the shelf. The storage and retrieval machine or transport vehicle then brings it to the relevant loading or unloading point in the warehouse.

Small, light and open: ctrlX CORE controls the shuttle

ctrlX CORE is part of the automation toolkit ctrlX AUTOMATION from Bosch Rexroth and controls the DAMBACH COMPACT SHUTTLE 2.0. One of the unique selling points: The controller works with app technology thanks to the Linux Ubuntu Core operating system. As a result, new functions can be developed and added easily in order to meet virtually all automation requirements.

In addition to the control system, the shuttle uses servo drives controlled by ctrlX CORE for the axis movements “running and lifting”. Among other things, DAMBACH uses the motor-integrated servo drive IndraDrive Mi from Bosch Rexroth. The shuttle runs completely independently with its own power supply. This is provided via PowerCaps for energy storage purposes. As a result the system can run independently of the storage and retrieval machine in the warehouse channels and store and retrieve goods. The PowerCaps can be recharged in just a few seconds on the storage and retrieval machine or transport vehicle, which means that the system can operate 24/7 without interruptions.

Thorsten Veit, Head of Control Technology at DAMBACH Lagersysteme GmbH & Co. KG, explained: “The control system ctrlX CORE is small, light and open. These properties made it extremely easy to integrate. Engineering and operation are equally straightforward. Programming the system requires no specialist knowledge. And the solution grows along with your requirements. It can easily be expanded with apps such as NodeRed for IoT applications. Thanks to the open platform design, new functions can be added to the shuttle at any time, thus ensuring that it remains future-proof and always on the move.”

DAMBACH decided to use components from Bosch Rexroth because of their compact, high-performance design. These properties mean that they have a key advantage compared to other solutions on the market. “It saves even more space in the shuttle and we can use the freed-up space to store our shuttle caps. System performance could therefore be improved further – with an increased operating time. Thanks to the more compact dimensions, the storage density in new projects can be increased significantly. A further advantage is the high resilience of Bosch Rexroth components – they are unaffected by external influences such as vibrations. That makes the shuttle even more robust,” said Thorsten Veit.

Bosch Rexroth will demonstrate this and other solutions for inbound, outbound and intralogistics of the future at LogiMAT in Stuttgart (Hall 6, Stand D31) from April 25 – 27.