Jorns, with its headquarters in Lotzwil, Switzerland, has been developing and manufacturing bending machines and accessories for sheet metal forming applications in the roofing, siding and plumbing industries since 1973. The company produces around 160 machines per year, including 125 standard bending machines, 25 double bending machines and 10 gutter machines, making it one of the front runners in the development, production and sale of this specialty equipment. In 2005, Marc Jorns took over as the second generation manager of this family-run company with 65 employees. With an outstanding dedication to quality and readiness to adapt products to the needs of its customers, Jorns provides a broad spectrum of sheet metal forming solutions.

Perfectly coordinated production processes

In the early 70s, Jorns was still using manual bending machines in production. As this solution became less and less economically feasible, Jorns began investigating alternatives and eventually equipped the first machines with hydraulic components. These were followed by an inhouse developed controller with electronic components. Early on, simple NC control was handled by a constant pressure switch. Since 2000, Jorns machines are equipped with a fully automated CNC control solution developed in-house and tailored to specific customer requirements and supported by the sheet calculation software CopraBend. This evolution of technological advances began with a simple, but powerful, hand movement. Jorns commitment to developing, producing and stocking virtually every component of its systems in-house allows it to perfectly coordinate its production processes.

Following development, Jorns systems pass through metalworking, large and small part milling, turning, coating, warehousing and control system development for final assembly and fine tuning. The systems are fabricated at each of these stations and finally assembled into machines with a length of 3 to 12 meters. The focus of production is on full functionality and reliable availability of the individual components. After all, the systems will later be operated all over the world – including in some countries where technical support involves considerable time and expense. Especially popular with customers are Jorns’ standard bending machine, the TwinMatic-Pro double bending machine and the gutter machine.

Developed in 2001 by former manager Kurt Jorns and his team, the TwinMatic-Pro double bending machine has an upper and lower bending beam that allows the sheet to be folded either upward or downward. This flexibility reduces the amount of handling required and accelerates the bending process, making Jorns a trendsetting frontrunner in the field of sheet metal forming. “We developed the Twin- Matic-Pro bending machine with groundbreaking technology that meets the highest demands coming from the roofing, siding and plumbing industries,” boasts Marc Jorns. Jorns machines continue to guarantee added value when it comes to efficiency, safety and flexibility – as well as an extraordinary openness to its customers’ special requests.

To make operation as streamlined as possible, the fully automated TwinMatic-Pro provides application-specific functions for sheet metal with a thickness of up to 3 mm (400 N/mm²) and an insertion depth of 1150/1300 mm. A unique feature is the programmable air gap, which, depending on the operating cycle (top and bottom bending beam), adapts automatically to the sheet thickness. The machine significantly increases throughput, while also providing the adaptability needed to accommodate a wide range of products.

Assembly and support simplified considerably

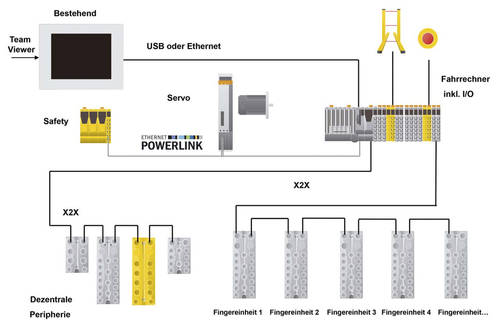

The TwinMatic-Pro double bending machine used to be equipped with Jorns’ own CNC control system. The clamping finger used here required a considerable amount of wiring when assembling the machine, so Jorns decided to pursue a more modern solution. They found what they were looking for at B&R, who are well-known for their modern and innovative automation solutions. B&R solutions have since helped Jorns make the biggest leaps yet in development of the TwinMatic-Pro. The machine has B&R control and safety technology, as well as the ACOPOS drive system. The remote X20 and X67 I/O systems round off the solution. These can be mixed and matched with various components to meet the needs of the application. “B&R gives us the transparency and flexibility we need, as well as the technical sophistication our machines demand,” says Jorns. “For us, the ease of use and comprehensive selection were the decisive criteria in favor of B&R,” reveals Pascal Guyot, department manager, MT Control Systems. Further advantages were gained with B&R’s X20 and X67 modules, for example, which reduced cabling by a third. It used to take three days for Jorns employees to lay the cables, but since they switched to the B&R modules they can finish it in one day.

The I/O modules from B&R are one of the most compact remote I/O systems available and are easy to connect to the control system. This solution allows Jorns to adjust the finger units automatically in advance, so in the future they’re even better prepared to meet their customers’ individual needs, even when this means adding finger units later on. Control quality was also improved by using a servo motor.

Uncomplicated handling with remote diagnostics

Powerful and precise diagnostics proved to be a further advantage. B&R’s remote maintenance solutions provide convenient access at lower cost. When isolating an error, X20 modules can easily be switched out – even without affecting operation. This is made possible by separated terminal blocks, ensuring that the machine’s wiring is not interrupted. The B&R X20 System provides rapid exchange of automation components while minimizing the risk of downtime.

Operation is further simplified by integrated safe update functions and remote diagnostics. The latter takes on particular importance when you consider that Jorns systems are operated all over the world, including locations where on-site service is extremely costly. “We are very happy with B&R’s products and have made substantial improvements to our production processes,” says Jorns, adding: “Since implementation, we’re seeing faster turnaround times and can handle orders more efficiently. The fact that we have a dedicated contact at B&R means we get exactly the kind of personalized service we hoped for.”

[info] www.br-automation.com [/info]