Procter & Gamble has set new standards for quality, design and innovation for nine decades. To produce innovative, high-quality technical products, Procter & Gamble, one of the world’s largest manufacturers of consumer goods, uses the HMI/SCADA solution zenon in both production and quality assurance.

Consumers throughout the world come into contact with the products of Procter & Gamble four billion times a day. The company, with more than 300 brands and more than 50 leading brands throughout the world, has one of the strongest portfolios of high-quality, proven products in the consumer goods industry. These brands include, for example, Pampers, Ariel, Always, Pantene, Pringles, Lenor, Iams, Oral-B, Duracell, Olay, Head & Shoulders, Wella, Gillette and Braun. P&G employs around 127,000 employees in approximately 80 countries around the world. In Germany, P&G has operated at 16 sites since 1960, including the Braun and Oral-B factory in Marktheidenfeld.

Fully automated production processes

Braun Oral-B Marktheidenfeld is specialized in large-batch manufacturing of electrical oral hygiene products and household goods. The factory is one of the most significant locations within the company. Production at Procter & Gamble is sub-divided into three levels. The first level includes injection molding, printing and prefabrication. The next level includes the brush equipment and the blister packaging equipment for the brushes. On the hird level, the fully automatic final assembly and subsequent packaging of the products is carried out. Today, the employees at the Marktheidenfeld site manufacture a total of 250 million finished products per year. In addition to the 27,000 household devices, the Marktheidenfeld factory produces 80,000 handles for the electric toothbrushes and 600,000 toothbrushes per day.

Customer orientation is of paramount importance

The manufacturing and distribution of products is now flexibly orientated to customer requirements. Procter & Gamble produces to order, so it can keep the storage costs low: „We adapt our production figures to demand on a daily basis, because market orientation is important to us. Flexibility is our strength“, explains Ralf Kaiser, Manager of SME Electric&Sensorics and Cybersecurity at Procter & Gamble in Marktheidenfeld. The production throughput times are less than ten days. In the process, the company places great value on product quality. The rating from Stiftung Warentest, a German consumer organization, is evidence of the high production quality. The Braun Oral-B Triumph 5000 with SmartGuide was the best in their test and the Braun Oral-B Professional Care 500 was the second best. The HMI/SCADA solution zenon from COPA-DATA is now used for the production and quality assurance processes of the Braun Oral-B Triumph 5000. Ralf Kaiser of Procter & Gamble: „We were no longer able to implement our wishes and requirements with the solutions that were previously being used; we had reached our limits. It was time to move in a new direction.“

Prozesstechnik kropf gmbh – the competent partner

Procter & Gamble commissioned Prozesstechnik Kropf GmbH with the implementation of zenon. The company, based in Upper Franconia with 40 employees, offers professional system implementations in the field of process control technology and data technology. Prozesstechnik Kropf has sold COPA-DATA`s visualization and process control system zenon since 1995.

„When selecting new solutions, two criteria always play an important role: Firstly the abilities of the product are of course significant and secondly, a competent provider that also assists us with project implementation on site and provides ongoing support with their expertise. Prozesstechnik Kropf GmbH has already proven their competence in many projects carried out for us“, explains Ralf Kaiser regarding the decision to use Prozesstechnik Kropf. The company has already worked for Procter & Gamble for ten years, having successfully implemented the building services control systems and projects related to the manufacturing of plastic parts. Prozesstechnik Kropf GmbH has also been active in the field of manufacturing for many years and has implemented various assembly cells together with the people responsible for these.

Zenon supports efficient final assembly

In recent years Procter & Gamble has gradually equipped the factory in Marktheidenfeld with new equipment for final assembly of the new Braun Oral-B toothbrush series. In doing so, 98 percent of all equipment and machines that are used are special machines. „This automated assembly is a technically-innovative process with highly complex processes. High equipment performance and a high depth of vertical integration characterize our production today“, adds Ralf Kaiser from Procter & Gamble.

When assembling the handles, the individual components such as the injection-molded plastic parts, the printed circuit boards, the gear mechanism (the oscillating crank), etc. are put together completely automatically.

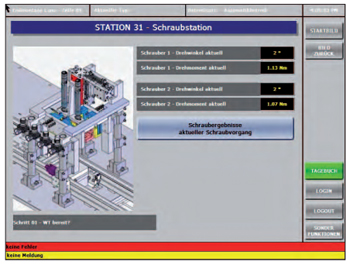

The HMI/SCADA solution zenon is used for, amongst other things, the final assembly line of the Oral-B Triumph 5000 in Marktheidenfeld. Here, the fully-automatic base assembly, a cell where functionality is checked and two manual workplaces are equipped with control panels. The employees operate the manufacturing cells with a zenon-equipped touch panel. Employees can use the individual menu items to carry out tasks such as changing between automatic and manual operation, testing each individual component in setup mode and looking at error messages. Amongst other things, the automatic screw machines are displayed for the base assembly, so that employees can orientate themselves quickly and easily. zenon monitors the angle of rotation and the torque, which are stored as parameters and limits. A fully-automatic check for functionality takes place in the testing cell: First the handles are placed on a rotating table by workpiece carriers in the testing cell. The rotating table with the (four) handles moves to the different testing stations.

The radio test, the press check and the camera check for the ring illumination are then carried out at the stations. Limits are defined for the individual testing mechanisms, which the person in charge monitors, administers and can also change using the zenon application. The employees check the quality of the products and use the touch panels to enter whether the product corresponds to the high quality requirements or if the handle needs to go for repair or refinishing. Here, employees can enter whether a defect in the plastic is visible, for example, or if there are switching errors. The errors that occur are then forwarded to a superordinate system by zenon.

Quality is the trump card zenon and straton are also used at Procter & Gamble for quality purposes. Here, the software supports two charging base test stations and a motor testing station. There, zenon visualizes the current power drain and the voltage and provides – if necessary – warnings in the event of the limit being exceeded. Prozesstechnik Kropf implemented the test cycle for the duration of the motors with straton. In addition, the employees in technical support use a mobile, zenon-equipped logging system in order to be able to log and evaluate data using the connections to various sensors. The employees can thus measure current, or pressure, for example. The information is available as a trend display for further evaluations and can be stored in an archive.

Zenon for the best user-friendliness

The global concern places a high value on modern and userfriendly technologies. Procter & Gamble has actively included all employees who work with equipment in the development of the new zenon application, including the new user interface, in order to be able to display their wishes and requirements in the new application. This also increases acceptance considerably when the solution is subsequently put into use. The employees in charge of software have developed a universal zenon menu, modified versions of which can be used in different cells. This includes machines and equipment layouts for example, which are incorporated into the application and the user interfaces of the individual stations. Employees can therefore immediately orient themselves with a machine or manufacturing cell that they do not use very often. The standard components also include assistance and control elements for the individual cells. „zenon makes it possible for us to implement all desired changes – requirements for quick project implementation, for security and most of all for usability. Here, our experiences with the previous solution showed that we could increase the user friendliness of the control panels. We now use zenon for this reason“, adds Ralf Kaiser. The user-friendly processing of all information includes, for example, the graphic elements on the display, the alarm list, the event list, the design of the controls such as buttons as well as the display of the bus status, including the Profibus participants (network participants). A clear overview of all data points allows quick troubleshooting in the event of a fault and thus ensures short downtimes.

Further expansion planned

Procter & Gamble is also planning to further expand its use of the HMI/SCADA solution zenon, in order to, for example, be able to produce toothbrushes for the lower price segments fully automatically and in large quantities. New cells are gradually being built and existing ones are gradually being converted. In short, a new line is being created for final assembly, with which the new control panels and zenon are to be equipped. Ralf Kaiser sums up: „Our objective is to establish a standard in production and to find a solution that will also be feasible for our equipment in the future. The zenon software is the benchmark for user-friendly guidance and has proven its ability in practice. We would like to establish zenon as a standard.“

[info] www.copadata.com [/info]