At the interpack from May 4 thru 10 2023, the main focus will be on the circular economy, resource conservation, digital technologies and product safety. In Hall 13, Stand E32, Baumüller will be showing, among other things, how, with intelligent drive and automation technology, machine manufacturers and end users can determine and optimize the CO2 footprint of their machines and systems in order to significantly reduce energy costs.

The circular economy meets energy efficiency: Baumüller has applied itself to this topic for many years. Above all, direct drive technology leads to significantly lower energy costs. Baumüller has also developed the smart energy monitoring software tool for optimizing processes in, among other things, packaging machines and presenting the energy costs transparently.

The integrated control mode enables the detection of vibrations in machines with a challenging design, to analyze them in realtime and to automatically optimize the process immediately. This measure increases the quality of the end product, since, for example, the sealing time for foil packaging in the process remains constant.

The following highlights will be presented on the exhibition stand:

Boost your Performance. Reduce your Footprint:

Alongside the current b maXX 5000 series, Baumüller will be showing the most important innovation in its product portfolio, the future servo controller generation, the b maXX 6000. This offers even better scalability as well as additional safety features, and smart Industry 4.0 functions, such as the energy monitoring integrated in the drive. Maximum control quality and dynamics as well as high power density are required in packaging machines – the ideal area of use for the space-saving b maXX 6300 module system. The new controllers are faster and more reliable than ever before. Despite the expanded functional scope, the firmware is fully compatible with the preceding b maXX 5300 family – a changeover is therefore possible without new programming or parameterization.

Smart Energy Reduction:

In a 3-axis exhibit, drive-based energy monitoring is used to present the drive system’s energy consumption transparently. This new software function assists in determining the product carbon footprint (PCF) and prepares for future documentation obligations within the scope of the EU’s Sustainable Product Initiative (SPI). With this function, for example, after a reference run, the travel distance can be optimized in energy terms and thus the CO2 footprint of the end product can be reduced.

Efficient design and open interfaces:

The ProSimulation software includes ready-to-use models for the Baumüller drive components and therefore enables dynamic machine simulation: Especially in complex applications, e.g. with non-linear kinematics or energy stores, drive components can be dimensioned efficiently. In addition, platform-independent models are available for motors and drives, which thanks to open standards such as FMU can be imported into an existing machine model, which was created with other commonly used simulation tools. Baumüller offers the creation of simulation models as a service.

IoT data exchange with ProDataX:

With ProDataX, Baumüller offers a new software tool for communication via the control technology through to the drive level. This makes platform and manufacturer-independent data transfer via OPC UA possible. ProDataX can run not only on the Baumüller control hardware but also on standard PCs with the Windows operating system.

Modular engineering for web processing machines:

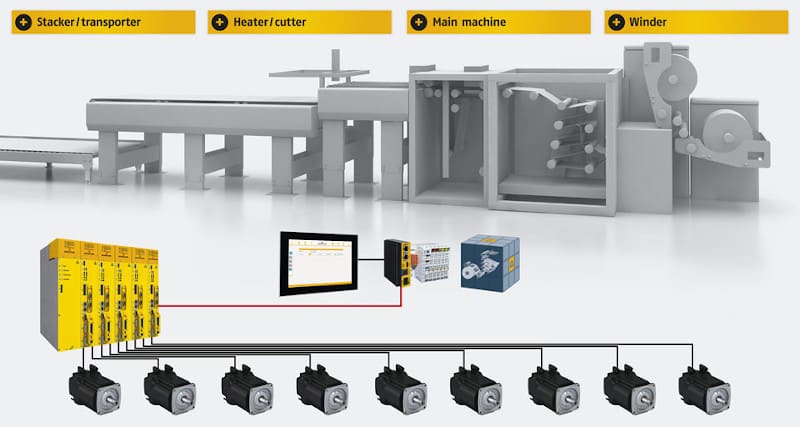

With the Web & Foil software template specifically for web processing machines, Baumüller is expanding its machine templates to include another industry solution. The template is suitable for machines and systems for paper and foil production, e.g. in foil bag, corrugated board and folded carton machines. It saves users time-consuming programming work since, alongside motion modules, it also contains templates for functions such as alarm handling or prepared visualizations. For the machine manufacturer, this means a faster time-to-market and significantly reduced development costs. Basic functions such as recipe or error management are implemented. Furthermore, machine-specific modules such as a cam controller and a register control are also integrated.

Water-cooled servo motors:

Water-cooled motors have many advantages: The active cooling increases the power density. In addition, close installation of multiple servo motors is easily possible due to the good heat dissipation. This saves space in the machine and the many axes is a positive aspect, particularly for packaging machines. Baumüller also offers all sizes of its servo motors with water cooling.

Life-cycle management worldwide

In addition to the development and manufacture of automation components, as a group of companies, Baumüller provides numerous services for plant and machinery manufacturing and for machine operators. From project planning, design and engineering through assembly and commissioning to maintenance, retrofitting and relocation, Baumüller offers support over the entire life cycle of machines and systems. With over 40 branches worldwide, Baumüller is a reliable service partner with decades of experience. Baumüller attaches particular importance to the sustainable and resource-saving production of intelligent drive and automation solutions.

interpack, May 4 – 10, 2023

Hall 13, Stand E32 – Messe Düsseldorf GmbH, Düsseldor