Don’t go airborne, but better safe than sorry if your application or its environment is at risk of explosion. TWK introduces a new safety encoder for explosion protection according to ATEX, Zone 1 / 21. Additionally with certificate for functional safety SIL2 / Performance Level d. There are many different applications. Simple and complex. Inexpensive and expensive. Non-hazardous and hazardous. Some of them are even explosive. The medium-sized company TWK has suitable sensor technology for almost all areas of application to convert mechanical into electrical measured variables or into electronic data.

The basic principle is: Safety first. In the context of the risk of explosion, the product range has been expanded with regard to sensors with ATEX certification. In addition to the sensors for zones 2 (gas) and 22 (dust), which have been available for a long time, a new generation of encoders with the future-oriented PROFINET interface is now offered (also with PROFIsafe profile), which is also suitable for zones 1 (gas) and 21 (dust).

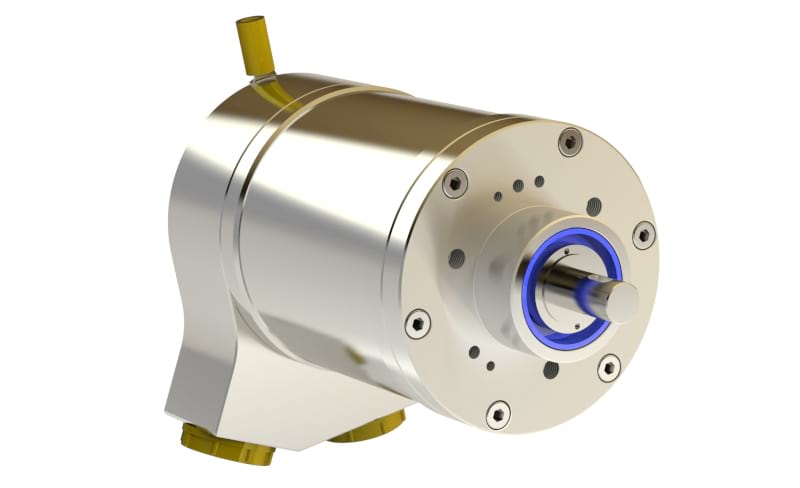

These are compact enclosures made of aluminium or stainless steel with cable connection, which not only offer the well-known robustness and reliability, but also unrestricted use in potentially explosive atmospheres as devices of ATEX group II, cat. 2, gas up to IIC and dust, as well as group dust IIIC. The certification is valid for, among others: ATEX, IEC-Ex, North America Class 1/2 Div. 2 and EAC-Ex. Of course also with SIL2/PLd certificate, if desired.

A wide field of application is the oil and gas industry. The vapours and gases that occur are explosive and any assemblies that come into contact with them must have the appropriate suitability. For example, if loading cranes, which are usually equipped with ample sensor technology – e.g. encoders – are used in ATEX zone 1, the new TRT78/S3-ATEX encoder with PROFIsafe interface can be used. It offers functional safety (SIL2/PLd) and explosion protection for Zone 1: safety in a double pack. The explosion protection is achieved by means of a flameproof enclosure with special cable glands in which the electronics are inserted. It withstands the explosion of a defective component. No sparks or heated gases can escape through the openings. Furthermore, the enclosure prevents dust from penetrating (IP6x). Since the surface temperature of the enclosure does not exceed 100 °C, gas and dust cannot ignite.

Although the features of the sensors are increasingly complex and the functions more extensive, the prices have not exploded. On the contrary. Optimised designs and production methods significantly increase efficiency and reduce costs.