Cincinnati Incorporated (CI) has been building sheet metal manufacturing machinery for 125 years and supporting those long-lasting machines for decades. The company can do this because it develops everything in-house, from hardware to software. But further developing its own control technology became too costly and difficult to support. According to CI engineers, since switching to PC-based control, there are only physical limitations to development.

Cincinnati Incorporated The Harrison, Ohio, company continues to be a leader in metal fabrication. Its reliable, high-performance equipment for bending, shearing, laser cutting and more has made it an iconic brand among U.S. machine manufacturers. At Cincinnati Inc., an “Own It” philosophy drives every aspect from product development and sales to long-term service and support, says Matt Garbarino, business unit manager, new equipment sales. “Machines we delivered decades ago are still in use and in many cases supported,” Garbarino says. “We still make replacement parts for equipment from the 1940s.” Of course, supporting both new and old devices is a challenge.”

Increasing pressure to innovate

With the CLX fiber laser system, CI had to develop more than just a next-generation laser cutting machine. Most important to its customer base (about one-third OEMs and two-thirds repair shops), the CLX had to be fast, intuitive, and reliable. Downtime is unacceptable for a laser cutting system because it creates a domino effect throughout a production facility. “If the laser breaks down, you have to send your press brake operator home, and then a few hours later you have to send your welder home,” says Troy Wilson, product manager at Cincinnati.

In the ’80s and ’90s, the company was a market leader as one of the first laser cutting machine manufacturers in the United States. But back then, it typically took about three years to be able to add or remove features or change the way we worked. Now it’s six to 18 months,” says Wilson.

Now, machines are becoming more complex, with handling systems being added to feed material during the metalworking process and remove finished parts. But CI’s old motion control system, provided by the previous vendor, wasn’t scalable and used a programming language outside the IEC 61131-3 standard. This slowed development and reduced the talent pool for hiring new engineers. In addition, CI’s customers wanted their machines to be periodically adjusted for higher wattage lasers and other features. Competitors required customers to purchase new machines, but CI faced excessive labor-intensive efforts to accommodate such demands. Future platforms would therefore require flexibility to allow devices to be connected and disconnected, and to easily change software parameters.

Always on the cutting edge of technology

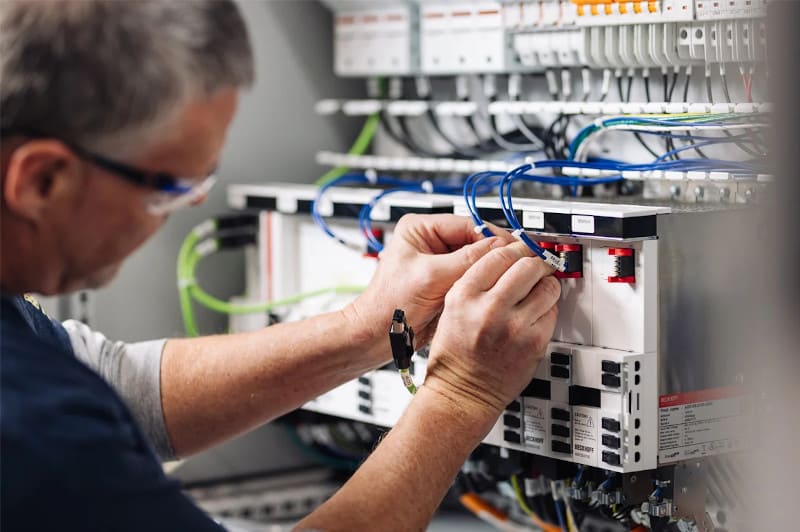

CLX fiber laser systems use an ultra-compact industrial PC (IPC) C6030 to control the entire CNC machine. The scalable machine controller provides ample computing power combined with flexible interface options. Best of all, obsolescence issues are eliminated. Beckhoff develops its PC-based controls and software to be backwards compatible and with future technological developments in mind.

“The big advantage that led us to Beckhoff was the promise that we would no longer have to worry about control obsolescence – Beckhoff takes care of this for the customer,” says Matt Garbarino. “At Beckhoff, IPC upgrades are a natural part of product development.” When we were building our own CPUs, it would be a disaster if a chip or other component broke. Having one supplier take care of all of this is a game changer for us.”

Choose from the latest programming standards

As a universal engineering and runtime platform, the TwinCAT 3 automation software also ensures future-proof scalability. From IEC 61131-3-compliant PLC languages with object-oriented extensions, to user-defined and predefined function blocks, to IT standards, the integration of TwinCAT into Microsoft Visual Studio® allows engineers to write programs in the language that best suits their application. This was a major step forward from the previous vendor-proprietary scripts.

The software-based oscilloscope TwinCAT Scope helped with debugging. Another advantage is the free engineering environment of TwinCAT, which only requires a license at runtime. “Creating a prototype system with TwinCAT is not expensive, and thanks to the programming flexibility we can regularly copy and paste software modules from one program to another,” says Zachary Bischoff, Head of Electrical Engineering at Cincinnati Inc.

Through the CLX user interface, access to the controls during machine operation has become even more intuitive. Operators and maintenance personnel no longer have to go through outdated ladder logic to troubleshoot errors or adjust the machine. The 24-inch dual-screen CP3924 control panel, mounted on a mounting arm, offers a generously sized and elegant user interface, customized with Cincinnati Inc. branding. Flexible automation with EtherCAT

Beckhoff’s EtherCAT industrial Ethernet system and servo drive technology provide even greater performance and scalability. In addition to fast real-time communication, EtherCAT offers free choice of network topology and manages up to 65,535 nodes in a single network. As an open protocol, it simplifies the connection to other industrial communication protocols. CI also uses TwinSAFE to add functional safety to the same I/O segment as non-safety devices.

“We use the wide range of EtherCAT I/O modules from Beckhoff,” says Zackery Bischoff. “The hot connect feature to plug and unplug EtherCAT devices during operation has proven to be very powerful, especially when used with our Automatic Nozzle Changer (ANC). This flexibility will become even more important as we integrate robots and even press brakes into our overall production line.”

The AX8000 multi-axis servo system offers a powerful motion control solution in a space-saving form factor. Each dual-channel drive can drive two AM8000 series servo motors, and thanks to One Cable Technology (OCT), a single cable can supply the motors with power and feedback signals. In addition, the Beckhoff servo solution offers high dynamics and precision.

“With our previous machines, we were limited by the control hardware and network. “That’s no longer the limit,” says Troy Wilson. “Physics is no longer our limit.”