Modern non-residential buildings place many high demands on building automation. These range from energy-efficient and sustainable building operation and comprehensive energy management through to the charging infrastructure for electromobility and fulfilling new legal requirements for recording energy and consumption data. This can be optimally implemented with EtherCAT-based control technology from Beckhoff, which provides an efficient central automation architecture thanks to ultra-fast data communication. In addition, a wide variety of network topologies can be implemented based on the client’s needs, and all established sub-bus systems can also be integrated into the topology with a high degree of flexibility.

EtherCAT celebrated its 20th anniversary in 2023, confirming its success as a high-performance real-time Ethernet system and open IEC standard for a diverse range of applications. These include a wide range of functions in industrial and functional buildings, such as air conditioning, lighting and shading, technical control centers for supply systems, event technology and measurement technology in energy distribution systems.

Fast, consistent, and reliable data acquisition is becoming increasingly important. Legislation now requires energy and consumption data for non-residential buildings to be recorded, which can only be achieved efficiently and cost-effectively with high-performance communication technology. The importance of a high data transmission rate is also confirmed by the VDI 3814 standard, Part 1 (Building automation and control systems (BACS) – Fundamentals). It states that the response times of building automation systems have a significant influence on their usability, as when a room automation system has limitless flexibility, fast communication between all segments, rooms, and areas is required.

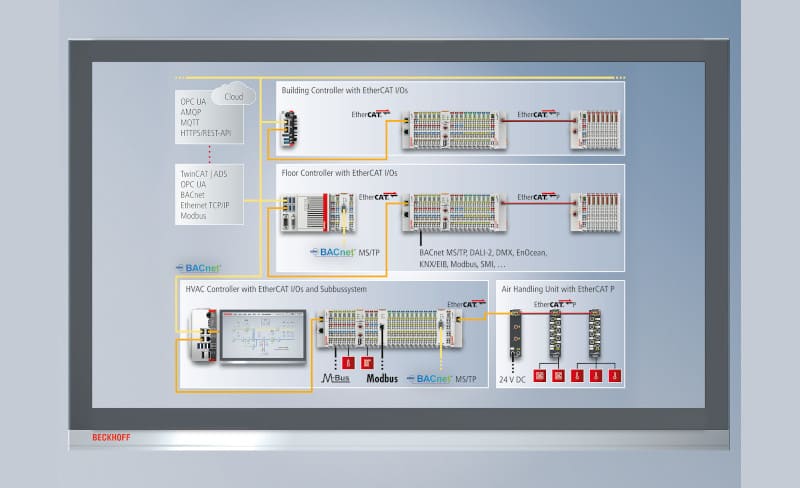

Specifications can be optimally implemented with the EtherCAT-based central automation philosophy. This is based on centralized control technology. This means that the control is distributed to one or more industrial PCs as required. This technology is supplied with the required data via decentralized I/Os and fast EtherCAT communication. A cost-optimized structure can thus be set up with as few controllers as possible which can then operate the required number of I/O components as an alternative to the more complex conventional approaches which generally have many controllers which only operate a few I/Os each. This central philosophy is supported by the openness of the EtherCAT-based system solution: EtherCAT provides a technological foundation for integrating all building automation fieldbus systems and thus avoiding the subsystem bottleneck that often occurs with conventional data transmission. BACnet/IP, BACnet-MS/TP, DALI, DMX, EnOcean, KNX/EIB, Modbus, M-Bus, MP-Bus, and SMI, for example, can be seamlessly integrated via the relevant EtherCAT Terminals and bus terminals.