The space industry is known for the fact that only the best is good enough for it: after all, applications in orbit have particularly high requirements with regard to reliability; and the environmental conditions during launch, operation and, if necessary, landing of space components are also extreme. Therefore, the industry has mainly relied on technologies developed specifically for this case of application so far – and then again and again appropriate applications were found for these on Earth. However, this approach naturally leads to high development costs and, not least because of quite modest number of suppliers, also to high costs for the components themselves and their operation.

For this reason, the space industry – not only the “New Space” companies with their unusual and pragmatic methods – is increasingly taking the opposite approach: what has been successfully proved on Earth can also work in space. The prerequisite, of course, is that the technology meets the additional requirements of the industry. And this is how the suppliers of space robotics came to EtherCAT: the leading communication technology for motion control applications on Earth suits perfectly for corresponding applications in space.

On the Space Symposium in Colorado Springs, which is considered the most important meeting place for the space industry, leading manufacturers of space robots, together with Beckhoff and the EtherCAT Technology Group, have published a white paper on “How Space Robotics benefits from the World Standard for Motion Communication”. This first discusses the general and specific requirements of space robots for a fieldbus technology. In addition to short cycle time and accurate synchronization, these include the availability of radiation-resistant chips, the ability to replace faulty nodes by reconfiguring the network, and the wide range of different devices available for easy setup of test environments and prototypes. Then, the white paper explains and discusses how EtherCAT meets these requirements.

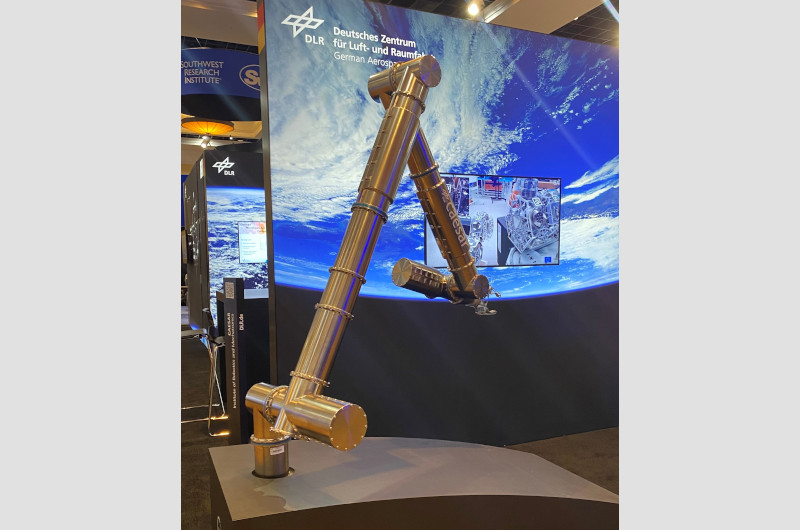

Among the companies involved in the co-authorship of the white paper is mda, the Canadian aerospace company currently developing the Canadarm3 robotic arms for NASA’s Lunar Gateway. Canadarm in the Space Shuttle and the Canadarm2 robotic arm are also from mda. The latter plays a central role in the spacewalks on the ISS. Motiv Space of California developed the robotic arm for NASA’s Mars Rover “Perseverance”, an arm more than 2 meters long with five joints that carries some of the Rover’s key scientific instruments for searching for signs of life on Mars. Tethers Unlimited is the manufacturer of the KRAKEN® robotic arm, which provides the space industry with a compact, seven-degree-of-freedom manipulator that enables small spacecraft to perform assembly, manufacturing, and maintenance operations in space. The Institute of Robotics and Mechatronics at the German Aerospace Center DLR has been using EtherCAT in a variety of applications for many years – and has already had EtherCAT-based systems in use on the ISS. The EtherCAT robot CAESAR (Compliant Assistance and Exploration SpAce Robot) was developed for a variety of tasks in space, such as assembling structures, maintaining and repairing satellites or removing space debris.

CAESAR was prominently displayed at the accompanying Space Symposium exhibition: the ideal place to present the white paper on EtherCAT in space robotics.