Do you know Andrew Ng, Lenze CEO Christian Wendler asks his guests upon arrival. “No? But you should, absolutely.” Wendler interrupts the Google search: “Ng is one of the most important AI pioneers of our time, millions of people around the world have taken his courses – including many Lenze employees. The American founded Google Brain, was a lecturer at Stanford, and co-founder of the world’s most popular machine learning course on Coursera.”

Wendler has clearly taken a liking to this man. And this man from Silicon Valley, the home of large data sets, has been talking publicly about smaller data sets for some time now. This made Wendler sit up and take notice, as this is also his story. The focus should be on the quality of the data in order to exploit the full potential of artificial intelligence, and Ng refers to this approach as data-centric AI. In the past, the main focus has been on developing, improving and fine-tuning algorithms. Can Silicon Valley ultimately learn something from discrete manufacturing, from the industry that has had to operate with small data sets for years? Perhaps, but what is much more astonishing is that Silicon Valley companies are discovering the industry for themselves and the many use cases on the factory floor. European companies are pleased about this, but new competitors are also entering the market – including industry-specific application knowledge.

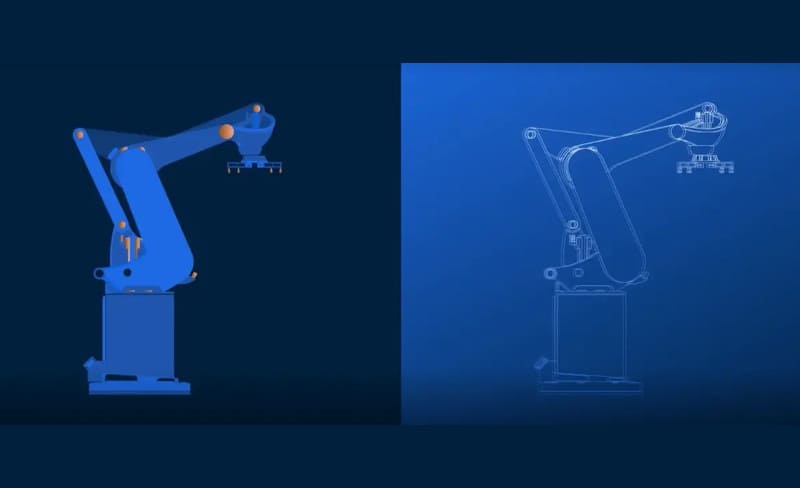

“Ng founded his own company just for this,” explains the CEO of German automation specialist Lenze. That shook him up. The entrepreneur knows that less data is generated in industry and that it is usually unbalanced. What’s more, data in industry requires domain knowledge of the production process. This means that companies need expertise in labeling the data. At the same time, engineers require their models to be explainable. Wendler is aware of the Americans’ ambitions. Like Ng and his colleagues, he relies on a data-centric approach with small data sets that are then turned into smart data. “In a big data approach, the user looks for correlations and patterns. One example is traffic planning. A machine or plant is a completely different application. Thanks to our process knowledge, I can specify search patterns to detect anomalies. I specifically extract only the ‘right’ data and evaluate it with my knowledge,” summarizes Wendler. He is proud of his team. His engineers rely on the digital twin. “The data from my machine flows into the digital twin – that’s the data pool, so to speak. I only fish out the data that I really need for my application. That’s my small data. And with my domain knowledge, I transform my small data into smart data,” adds Wendler. It is important to him: “We don’t always need deep neural networks; we can also quickly identify what works how and where there is potential for optimization in the digital twin.”

OEE optimization generates 45 billion euros

Together with their customers, the automation experts have identified four smart data approaches. “When engineers in Germany plan a new machine, they play it safe. After all, German engineering has always been a seal of approval for top quality and reliability. Even today, many engineers oversize the requirements because they want to ensure that the system over-performs,” reports Wendler. Experts refer to this as the cascaded buffer syndrome. This leads to unnecessary waste. “We can test the exact, performance-oriented design in the digital twin of the machines,” says Wendler enthusiastically. This saves energy, material, weight, and transport costs.

The CEO calculates: “If we use the data in the twin andour smart data approach for even just 25 percent of the 50 million electric motors worldwide, i.e. 12.5 million motors, we will save around 500 million euros in electricity costs per year and over 2 billion euros in manufacturing costs.” Wendler is now in his element. He picks up a brown parcel. “We can save an enormous amount of energy in the e-commerce warehouse,” he promises. Many conveyor belts run at full capacity for 20 hours a day. “But we have to take a close look at the utilization data and then it becomes clear: The customer only needs the maximum load for one hour a day.” The electrical engineer takes a block and does the math. “With the digital twin and thus intelligent load-optimized motion control and efficient motors of the latest generation, I can achieve an impressive result: The energy consumption of a typical e-commerce facility with 800 motors extrapolated to 13,000 parcel centers worldwide saves 31 TWh. That corresponds to the CO2 emissions of around four million mid-range cars. We assume that such an approach would enable energy savings of up to 50 percent for all production machines and conveyor systems.” He underlines the 50 percent with two dashes. “These are values. We use data to create real added value,” says Wendler proudly.

And then he puts a big number in his mouth: “The OEE is hovering at 60 percent worldwide. We have calculated a potential for improvement of 45 billion euros. Deloitte says the same thing. 45 billion,” he pronounces the figure slowly. The assumption: In 36 months, 82% of plant operators worldwide have at least one unplanned machine downtime, most of them two or more. Many systems are still maintained according to the “run-to-fail” principle, which means that machine parts are only replaced when something breaks. And: on average, production systems at every manufacturer are down for 800 hours per year. Car manufacturers estimate a loss of turnover of around 20,000 euros per minute of downtime. “And this is where we come into play with our machine learning models. Thanks to predictive maintenance, trained on a small data set, I know when my timing belt will break and the customer can order and replace the part in good time.”

But does he have all the skills in-house? Ng and his colleagues do nothing other than train AI models. “Yes, we have them too, and they also know the customer’s plant and work with the plant’s digital twin. We can reduce design effort and JBN time. We swap models, can quickly adapt them to other customer systems and save money, time, energy and resources.” And Ng? He would love to meet him and show him our Mechatronics Competence Campus. Wendler jokes that his team can soak up domain knowledge there. “The invitation has been extended.”