With the continuous development of industrial automation, robotics and CNC machine tools, servo motors play an important role as a motor that can accurately control Angle, speed and position. The power of the servo motor, that is, its rated power, is an important indicator to measure its output capacity. However, when choosing a high-power servo motor, we need to consider a variety of factors, including voltage, speed, torque and efficiency. This article will explore the key factors in choosing a high-power servo motor, and use Wacoda as an example to introduce its solution focused on motion controllers and servo systems.

When choosing a high-power servo motor, we first need to understand the demand for motor power of the production equipment we use. In general, 100W-750W servo motors are the common power range. The high-power servo motor generally refers to the motor above 1KW. Therefore, we need to choose the appropriate power servo motor according to the actual needs of the production equipment. In order to ensure that the selected motor can meet the requirements, we can choose a motor with similar power to test, and use it after the test is qualified.

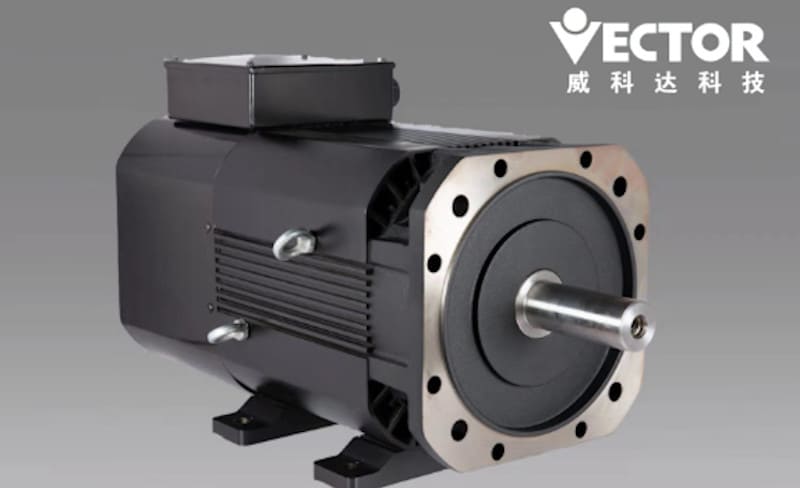

As a company focusing on motion controllers and servo systems, Vector is committed to providing professional, personalized, simplified and applicable motion control solutions for middle and high-end equipment manufacturers. Over the years, Vector has been focusing on research and development, production and application, and constantly promoting the development and innovation of servo motor technology. Through continuous improvement and optimization of products, Vector has established a good reputation in the field of servo motors.

When choosing a high-power servo motor, we also need to consider the following factors:

- Power requirements: Determine the required servo motor power range according to the needs of the production equipment, and select the appropriate power level.

- Load requirements: Considering the requirements of torque and speed of production equipment, select the servo motor that can meet the load requirements.

- Control system: Ensure the compatibility of servo motor and control system to achieve accurate Angle, speed and position control.

- Efficiency and stability: pay attention to the efficiency and stability of the servo motor, choose a motor with high efficiency and stable performance to improve production efficiency and product quality.

To sum up, choose the right high-power servo motor needs

Power requirements, load requirements, control system compatibility, efficiency and stability are taken into account.