Despite more than two years of uncertainties as a result of the pandemic, manufacturers of products using technology from PROFIBUS & PROFINET International (PI) have reported very positive figures for 2021. This is especially true for PROFINET and IO-Link, thanks to years of consistent development of the technologies and coordination with users. The latest example of this is the publication of specification documents on Ethernet-APL.

“Ethernet-APL hasn’t contributed to the current figures just yet, but it’ll ensure the widespread use of PROFINET throughout process automation in the near future. The reason for this optimism is the very highly rated demo systems of users in the chemical industry,” said Dr. Jörg Hähniche, head of the APL project.

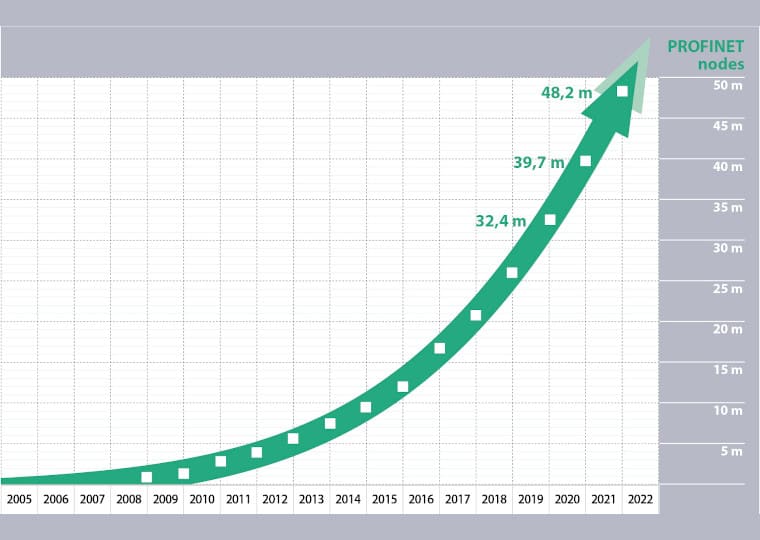

8.5 million PROFINET devices were installed in the market in 2021 – the largest annual figure yet. This corresponds to an increase of more than 22% and a total of 48.2 million devices. Though the 1.5 million PROFIBUS devices installed in 2021 is somewhat less than the previous year, the total number of PROFIBUS and PROFINET devices installed came in at a record 10 million for the year.

The biggest year-over-year increase in 2021 was 30% seen by IO-Link. This is nearly the same growth rate as the prior year and proof that development of IO-Link is pointed in the right direction by active experts in the working group. They have also been making consistent progress with IO-Link over SPE. The annual figure of IO-Link devices installed amounted to 6.3 million nodes, and the total number is now over 27 million.

The figures for PROFIsafe (2.6 million) and PROFIBUS in process automation (0.8 million) remained steady in 2021 compared to the previous year. The total number for PROFIsafe is now close to 19 million, and a total of nearly 15 million devices have been installed altogether for PROFIBUS in process automation.

“The continuing positive trend for products with PI technology on the market is based on the user’s trust in having bet on the right horse. And this is no coincidence. In our active working groups, a large community is continuously developing sustainable communication and information standards, which offer our users technologies for implementing digital production in line with Industry 4.0,” said PI Chairman Karsten Schneider. “Motivated by market success, our working groups are deeply committed to a number of projects. We hope to be able to present our technological developments in person at this year’s Hanover Fair after being away for more than two years,” added Schneider.