UniversalAutomation.Org is a recently created independent non-profit association. What is your philosophy and goals?

UniversalAutomation.org has been formed by a diverse group of industrial leaders and pioneers who have joined together to advance the world of industrial automation.

For the first time, IT, OT and software vendors, end users, systems integrators, OEMs, start-ups and higher education institutions share a common automation software layer across their products and solutions—regardless of brand. This new level of shared technology provides the basis for an ecosystem of portable, interoperable, “plug and produce” solutions and creates an entirely new category within industrial automation.

This common automation software layer is a runtime execution – based on the IEC 61499 standard – that enables the decoupling of automation software from the hardware it executes on creating an entirely vendor-agnostic ecosystem for automation software development. Decoupling hardware and software will ease and support the merge of both the information technology and operational technology worlds to unleash the full potential of Industry 4.0.

UniversalAutomation.Org is based on the IEC 61499 standard for distributed automation, can you explain what this standard consists of?

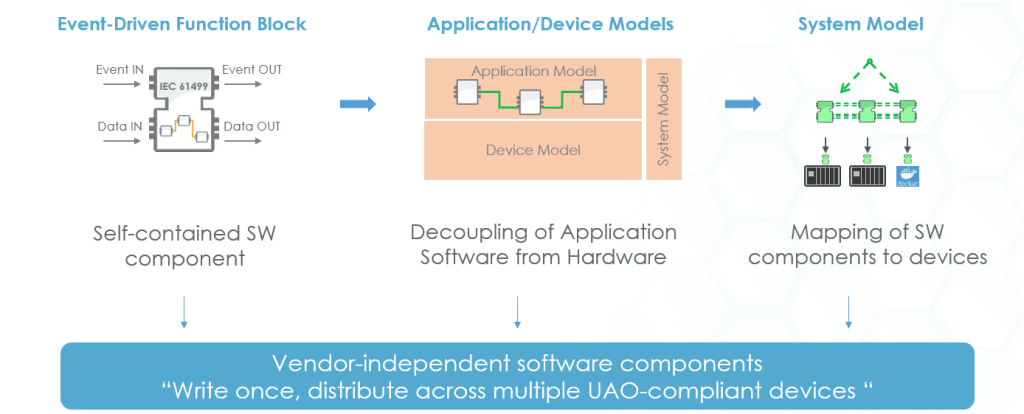

The IEC61499 standard is the technology enabler behind UniversalAutomation.Org which makes the decoupling of hardware and software possible. It is a system-level design language for distributed measurement and control systems which solves the problems of ensuring portability, configurability, and interoperability of application software across vendors and, at the same time, permits software and hardware decoupling.

It starts with event driven function blocs with are only accessible through their interfaces. Those function blocs can be easily understood by people coming from the IT as being stand alone, hardware independent software components. The application model rules how to create an application by plugging together multiple software components. The device model describes on which devices the application will run onto. And last, but not least, the system models that describe the mapping of the software components to the different devices. You can already see that the decoupling of hardware and software comes directly from the standard itself and enables the reusability of software components. Imagine that tomorrow you want to connect your machine or process with a digital twin, instead of having to create this connection yourself, you just need to go and find the proven-in-use software component that just does it. “Stop reinventing the wheel!”

What companies are part of the project?

UniversalAutomation.Org current members include a diverse group of industrial leaders and pioneers – including IT, OT and software vendors, end users, systems integrators, OEMs, start-ups and higher education institutions.

Members will develop and adopt the next generation of universal automation solutions—software components that bring unique values to users, based on the IEC 61499 standard. They will also increment a shared runtime and champion its use. Members will have access and the ability to shape the runtime implementation. Applications for membership are open to all, everyone is encouraged to join.

A full list of members includes: Aalto University, Actemium, Advantech, ASRock, Asus, Belden, Cargill, Dynamic Process, eaw Relaistechnik GmbH, ESA, ETP, ExxonMobil, Flexbridge, gr3n, Hirschmann, HTW Berlin, Huazhong University of Science and Technology, Intel, Jetter, Johannes Kepler University Linz, Kyndryl, Kongsberg Maritime, Luleå Technological University, Lumberg Automation, Mayer, Phoenix Contact, ProSoft, R. Stahl, Schneider Electric, Shell, TaoTech, Upstate Automation, Wilo, Wood and Yokogawa.

A current list of members can be found on our website: UniversalAutomation.org

How can users benefit from this New Automation Era that offers UniversalAutomation.Org? How is the response from users?

Users will benefit from the fact that more and more UniversalAutomaiton.Org-compliant products will be available on the market.

After only one year of existence, there are already more than 5 offers available which support hardware independent programming.

Hardware independent programming means:

• More cost effectiveness: write once & re-use, regardless of the vendor

• More reliability and safer using proven-in-use software

• The possibility to incrementally improve over the lifecycle of the plant

• End-of-life proof: re-use software even when the automation hardware is obsolete

• Embed & re-use IP to protect competitive edge and gain a better return on invest on increasing software development

• Train you team in one system only instead of multiple as it is done today

How would UniversalAutomation.Org differ from, for example, PLCOpen?

UniversalAutomation.org is a technology enabler for other initiatives aiming at a more open automation world.

We see for example the first implementation of the UniversalAutomaiton.org (UAO) technology to implement the MTP standard or the use of UAO on a OPAF test bed led by ExxonMobil.

UniversalAutomation.Org is not creating a new standard. UniversalAutomation.org is managing a reference runtime implementation of the IEC 61499 standard on a shared source basis which is similar to what is done in the IT world.

You could give us an example of what plug and play automation with vendor independent automation would be like thanks to UniversalAutomation.Org

This combination of a technology enabler of hardware and software decoupling combined with a community of users and vendors committed to the technology will enable our plug-and-produce vision where complex automation applications will be solved simply using proven-in-use software components: As an example, if I want to send data to Amazon Web Services, or if I want to connect my machine or process to a digital twin, or if I want to implement an advanced model-based control algorithm… Go find the proven-in-use software components instead of having to recreate it yourself.

What current PLC programming software is compatible with the UniversalAutomation.org runtime?

Schneider Electric’s EcoStruxure Automation Expert is built on the UnviersalAutomation.Org runtime and is already available today for you to test and try out. With the creation of UniversalAutomation.Org, products from other vendors embedding the UniversalAutomation.org runtime are already in prototype stage and will be commercialized in the coming months.

Is UniversalAutomation.Org the golden dream of standardized PLC programming capable of running on hardware from different manufacturers?

One of the principle aims of universal automation is to ensure that a) application software can be deployed to hardware from different vendors and run without any modification, and b) that an application can be distributed to multiple controllers from different vendors and those controllers will interoperate with each other automatically to execute the distributed application.

The shared source principle is used to ensure this portability of applications and interoperability of hardware by avoiding multiple incompatible versions of the runtime in the market. The development of this universal automation runtime is managed by the UniversalAutomation.Org members using a voting system. The number of votes of each member is determined by the member’s membership level.

What is your vision on how leading manufacturers in the sector and with proprietary systems (Siemens, Rockwell, Omron) will welcome this initiative?

We see that more and more initiatives coming from both users and vendors are created around more Open Automation and UAO answers exactly to this demand.

Interoperable and portable application software is an essential enabler for next-generation industries. The more vendors can offer this new standard to customers, the faster we can unleash the potential promised by the Fourth Industrial Revolution.

Adopting a shared automation layer, common across vendors, will provide limitless opportunities for growth and modernisation across industry. The ARC Advisory Group found this move could save the industrial market $30 billion each year that is currently spent servicing and maintaining the install base of proprietary systems.

UAO proposes a unique platforming possibility so that different suppliers can work together on a common runtime execution engine and increment it to better answer the demand of the automation users. UAO will welcome any member who wants to contribute to broaden the ecosystem of universal automation products.

What is the vision of UniversalAutomation.Org on the current crisis of components and the problems that many OEMs have to be able to deliver their machines and how UniversalAutomation.Org can be part of the solution to this type of problem?

Decoupling hardware and software surely helps especially now because OEMs could switch hardware without having to adapt their software. This is a huge gain compared to the present situation.

UniversalAutomation.Org will be present at the next SPS 2022 fair, what can visitors to your stand see?

At SPS 2022, we will officially disclose our demo wall with products from different suppliers that supports portable software application and a real customer use case of the technology in the sustainability domain with the company Gr3n.

Finally, what are the objectives of 11. UniversalAutomation.Org in the short and medium term?

We want to grow in term of members to support the initiative and have more products available on the market. The goal for 2023 is to double the offering that we already have today. UAO is open to everybody so feel free to contact us and join this initiative. On a side note, UAO also provides training to its members and access to a free programming

Greg Boucaud, Chief Marketing Officer at UniversalAutomation.Org