IXON, provider of solutions for remote machine service and maintenance management, today launches the new IXON Cloud 2 platform. The completely redesigned IXON Cloud is refined in many ways to satisfy customer demand for improved collaboration features and allows users more freedom to customise and set up the platform to best fit their specific needs.

IXON’s mission is to stimulate and accelerate the IIoT transition among machine builders by providing a secure cloud environment with all the technology needed to make IIoT directly accessible for every machine builder around the world.

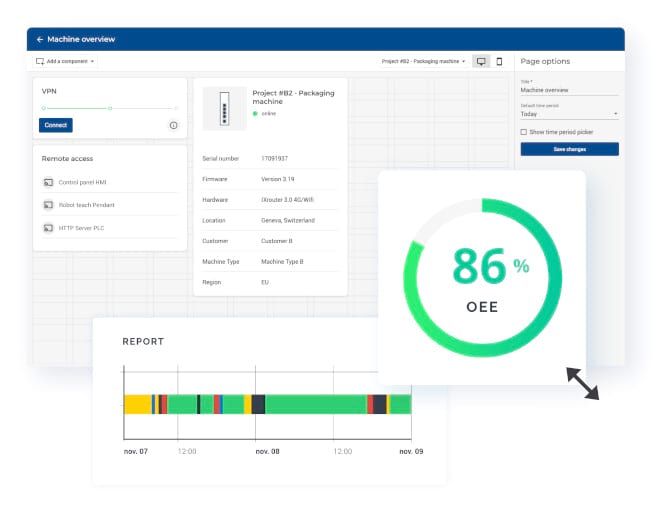

Today, IXON Cloud is the most complete IoT platform for the machine builder, allowing them to create their own IoT portal, connect machines, collect data, create alerts and remotely troubleshoot as if they were on-site – with just a few clicks.

To take things one step further, IXON has been hard at work behind the scenes on IXON Cloud 2. New features of the IXON Cloud 2 platform include:

- Clean intuitive interface to eliminate distractions and bring focus to your daily tasks;

- IXON Studio for portal customisation and dashboard building;

- Role-based user management for advanced, fully customisable access and control rights.

Willem Hofmans, CEO at IXON, said: “Collaboration is the central pillar of IXON Cloud 2. Collaboration to allow a machine builder to maintain relationships with its customers for decades. We are on the eve of a significant transition where machine builders start using all their knowledge and skills not only in the development, construction and installation of a machine, but where their knowledge and skills are of great value throughout the entire life cycle of a machine.

“IXON pledges to help guide companies along the transition and to support the machine builder at all times in the best way possible. This allows machine manufacturers to focus on the core of this transition: their business processes.

“Figuring out, together with partners and customers, how to combine machine data and extensive process knowledge to provide highly valuable information and advice. To prevent stagnation and ensure that machines are continuously improved and fully empowered during their entire lifespan.”