The Swedish company Cognibotics was searching for the perfect robot controller when it came across KeMotion. The challenge was to solve the challenge of automating goods picking in logistics facilities using a new innovative robot with an unparalleled combination of speed and reach.

The legendary meeting between Cognibotics and KEBA took place at automatica 2022 in Munich. Fredrik Malmgren, CEO of Cognibotics, began the meeting with a clear statement: “KEBA Industrial Automation was the right choice because the Swedish company based in Lund had exactly the right piece of the puzzle.” What was still missing for the market launch of the innovative high-performance robot HKM1800 for material handling was KEBA’s robot solution, KeMotion, based on the Kemro X automation platform.

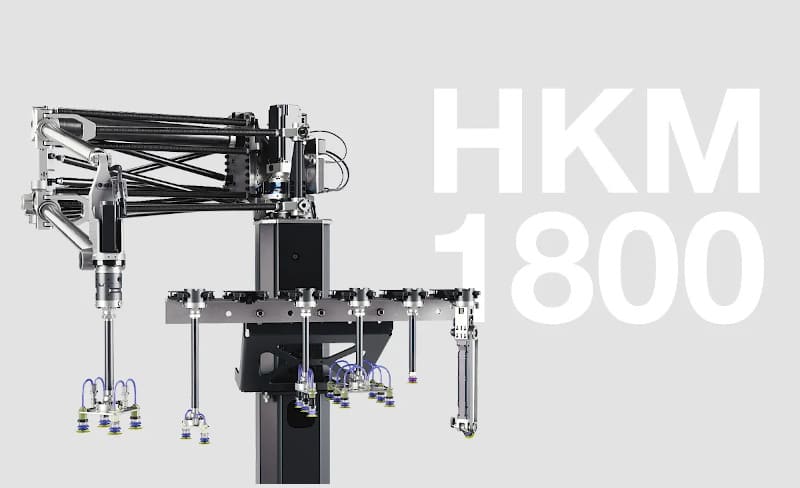

HKM stands for Hybrid Kinematic Manipulator

The name comes from the combination of the advantages of serial and parallel kinematics. It is an innovative hybrid. This design allows for minimal moving masses in large circular working areas and the shortest cycle times.

“After reading the name of the KEBA software interface call, we realized that this system is not a simple robot add-on for a PLC, but a ‘real robot controller,’” say developers from the Malmgren team. For more than two years, they have been searching for a suitable control and platform solution for the HKM1800, a handling robot for order picking that could revolutionize the entire industry. Malmgren explains: “We needed a sophisticated and complete robotics platform that would allow us to fully utilize our own know-how. Only the KEBA robotics environment could provide this, and we were able to integrate our technology there without any problems. The result is a unique product that cannot be easily replicated.”

Cognibotics was founded by Klas Nilsson in 2013 with the aim of developing advanced robotics technology and state-of-the-art industrial robots for material processing and handling applications. The company currently employs more than 40 people. Fifteen of them come directly from science, many others have decades of practical experience in industrial automation or industrial robotics. “We were never a typical startup. If you add up the robotics experience of all our colleagues, we easily reach 100 years,” says Malmgren.

After the trade fair in June, Cognibotics and KEBA immediately started their cooperation. The HKM is expected to be on the market within a year. Michael Garstenauer, product manager at KEBA, explains: “The challenge for Cognibotics was to enter the production sector with the HKM1800, which places high demands on reliability, service, availability of spare parts and technology.”

Thanks to Cognibotics’ precise requirements, this ambitious goal was achieved. After only a short time, Cognibotics was even more amazed by KeMotion’s capabilities. “In fact, we ran the system for a few days and it didn’t crash or freeze. We were very surprised,” says Malmgren. Six months later, in January 2023, the HKM1800 was finally fully functional in the lab and ready to be delivered to the customer world. “We knew the schedule was ambitious, but by using KEBA’s robotics solutions we were able to reduce our development time by a factor of four, which is something we would never have been able to achieve otherwise.” “This short time to market is crucial for the future market success of the HKM1800,” says Malmgren. Global supply bottlenecks have led to some uncertainty as to whether the project will be completed as planned in 2022. Computer parts such as the engine were also affected. “Thanks to KEBA’s own products, we were able to overcome this challenge much better than the market,” Malmgren recalls with a laugh.

Four times faster than humans

High-performance robots open up completely new possibilities for robot-assisted picking processes. This is especially true when multiple pick-and-place positions cover a large working area, as is often the case in warehouses and distribution centers within logistics facilities. Malmgren explains: “While a human can maintain a pace of 300 to 500 pick-and-place cycles per hour, the HKM 1800 can reach much further than a human can, allowing it to exceed 2,000 cycles per hour.”The -and-place robot can sort complex goods such as fruit, vegetables and flexible items into boxes four times faster than a human.

Compared to conventional SCARA, Delta and 6-axis robots, it is optimized for pick-and-place applications with superior performance and the right degrees of freedom. The HKM1800 has a maximum load capacity of 7.5 kg, a reach of 1,800 mm and a working area of 10 m². “We based our design on a German truss bridge. It’s made from lightweight, high-performance materials, with the arms made from carbon fiber and the joints in aluminum,” says Malmgren. “We placed all the servo motors and gearboxes in a central point that barely moves. We’re using the laws of physics, which means that all moving masses are super light and all heavy masses are essentially stationary,” enthuses Malmgren. The HKM1800 is constructed with almost no moving mass, delivering maximum performance with minimal energy consumption.