With the motto “It’s not just about industrial automation, it’s also about turning your ideas into reality” KEBA was presented at the SPS 2023 fair held last week.

As last year, the complete industrial automation provider based in Linz, Austria, focuses strongly on exchange and dialogue. During the SPS 2023 celebration, KEBA showed interesting new developments in its portfolio of solutions for industrial automation.

Robotics solutions

When it comes to robotic solutions, there are several highlights. The drag&bot team (part of the KEBA Group since November 2021) will present the simple integration of robotics with a demonstration. The drag&bot module is now an integral part of KEBA’s Kemro X automation platform.

Another focus of attention in the field of robotics is the official announcement of the cooperation with RoboDK. RoboDK was founded in Canada in 2015 and specializes in offline robot programming and simulation. Offline robot programming is programming outside the production environment. Its goal is to eliminate production downtime caused by programming robots on the shop floor.

Simulation and offline programming allow multiple scenarios of a robotic work cell to be studied before setting up the production cell. This includes optimal positioning of the robot to minimize cycle times, avoid singularities or ensure accessibility. In-office preparation reduces commissioning times.

The functionality currently available allows the creation of robot programs in the KEBA KAIRO language within the RoboDK environment based on 3D models of parts and systems. An easy way to transfer programs to KeMotion controllers is also available. The execution of the robot’s movement can be monitored in a digital environment as well as with the real robot controller within RoboDK. Other improvements include workflows for system design and implementation, as well as after-sales support.

KEBA KeDrive D3-AC

Modular machine concepts require flexible and compact drive systems. The new KeDrive D3-AC from KEBA is a servo controller that integrates AC mains connection, mains filter and braking resistor, as well as three-axis controllers in a single device. The three-axis servo controller was developed by focusing on three-axis manipulation kinematics.

Especially Cartesian robots often require higher drive power in one of the axes. For this reason, variants with rated current of 4 A/4 A/6 A or 8 A/8 A/12 A are available for the three-axis drive.

If a central control cabinet is used in one solution, in the other solution the drive technology is integrated directly into each module. For the core solution, the first option is energy-efficient multi-axis drives with common DC power. In the modular solution, where normally only a few units are used, it is important to use compact all-inclusive units.

The new KeDrive D3-AC is an integral servo drive that integrates the AC power supply, a line filter and the braking resistor. A special feature is that up to 3 axis controllers have been integrated into one device. This allows for a very compact design and an extreme reduction in wiring effort. The portfolio also includes single- and dual-axis servo controllers.

KeDrive D3-AC is part of the KeDrive D3 family of drives. The KeDrive D3 multi-axis drive system is an economical solution for machines with a higher number of axes. For a smaller number of axles, KeDrive D3-AC is now an even more cost-effective solution.

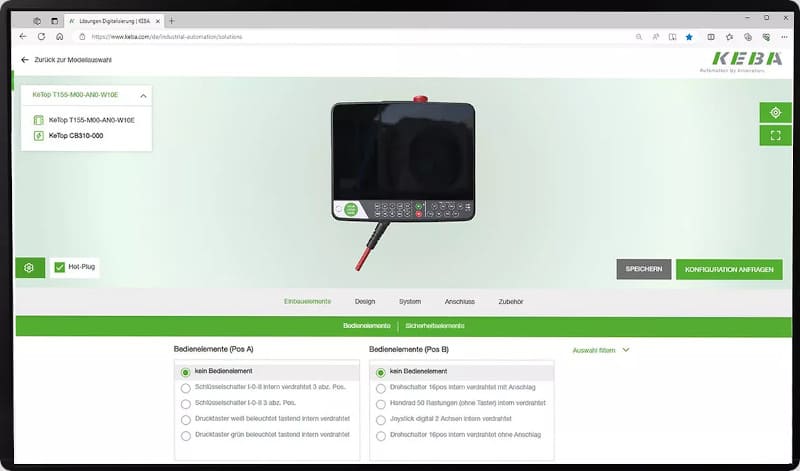

Mobile handheld KeTop T135

In the area of HMI, the KEBA team has shown several highlights at SPS 2023. In addition to Safe-Wireless and the adaptive rotary push button “KeWheel”, a product configurator will be presented for the first time. In this configurator, users can configure mobile and fixed KeTop panels according to their own needs or requirements with just a few clicks. Users can choose from a large selection of KeTop “Basic” handheld computers and configure the desired keyboard and layout, as well as mounting hardware, in just a few steps. Appropriate accessories such as junction boxes and cables can also be configured.

After online configuration, visitors can assemble the portable terminals themselves at a dedicated station: all integrated elements can be plugged in themselves.

The KeTop T135 is equipped with a 7″ multi-touch display and, thanks to the browser, can be used for all modern display tasks and, thanks to the Ethernet connection, with any control system. The T135 convinces with its ergonomics, its Compact size and very light and the keyboard located on the back allows practical one-handed operation.

The KeTop T135 can be equipped with up to three control elements. Discover the wide range of configuration possibilities thanks to the large selection of optional control elements.

Artificial intelligence

The Artificial Intelligence team demonstrated through a game how artificial intelligence can be integrated into a control process, for example to recognize and track objects in real time. The team will also present the KEBA AI development kit. The DevKit, which is currently in prototype status, consists of a Linux-based KEBA C5 controller that includes I/O cards and the AI extension module.

This extension module was developed specifically for AI applications in an industrial environment in compliance with all relevant standards. The toolchain it contains includes all the tools to train models for the AI plugin.

Additionally, function blocks are available that allow models to be run directly in the PLC code. In this way, industrial companies that need AI can quickly enter the world of neural networks and add the added value of AI to their plants.