In the drive to reduce packaging and its resultant waste, a specialist machinery builder has developed a pressureless queuing conveyor for collating quiches prior to baking.

Western Mechanical Handling (WMH), of Callington in Cornwall, designs and builds innovative production machinery for the food, pharmaceutical and similar industries where the product is delicate and requires careful but high speed handling. Its automation department, WMH Automation has over the years developed considerable expertise with, amongst other technologies, Mitsubishi Electric precision servo drives. Uncooked quiches are difficult to handle, the filling being liquid and the raw pastry being soft. But when manufactured in commercial volumes they need to be moved quickly through the production process, so are in danger of collapsing and thus disrupting production.

In the past the solution was to use an aluminum foil dish to hold each quiche as it was made and cooked. The quiches could thus be handled relatively robustly, bumping against the side of various machines and often being bunched together against a stop bar at the end of a continuously running conveyor. The dish then became part of the final packaging, and often the quiche had the double protection of the dish and an outer cardboard box or sleeve.

However, as social awareness of environmental issues has increased, consumers have begun to demand reduced packaging. In the case of quiches and similar products there is a move to paper flan dishes, similar to but larger than those used for cup cakes and muffins. This has created a dilemma for many food manufacturing companies, because the customers still expect their purchases to be pristine and undamaged on shop shelves.

“We have addressed this sort of issue several times in recent years for different customers,” says Matt Hurley of WMH. “We have developed two or three concepts that can be adapted for a number of different applications.”

“The quiche project gave us a chance to perfect what has become known as pressureless queuing or collating. In fact it is applicable to any product, pies and pizzas for instance, although it could also be used way beyond the food industry.”

The problem WMH had to solve was collecting randomly arriving raw quiches into neat rows of set numbers with orderly spacing between them so that they can be transferred onto a conveyor oven for cooking.

The solution they developed was an in-line servo-controlled collating conveyor and intelligent sensing system. Quiches are delivered to this from the main conveyor at random time intervals, the sensors identify the position of the next quiche on the main conveyor, calculate the time until its delivery and adjust the collating conveyor to optimise the spacing between the quiches. If there is a long wait until the next quiche arrives, the collating conveyor will pause.

When a line of quiches is complete they are transferred laterally into the oven, through which they pass to emerge cooked and then proceed into a freezer to reduce their temperature ready for wrapping and boxing up.

Like all the best machine designs the principle is simple. This means we are able to easily adapt it or add in some extra capabilities for specific applications,” explains Matt. “For the quiche job, the collator is actually made up of three smaller independently controlled conveyors.”

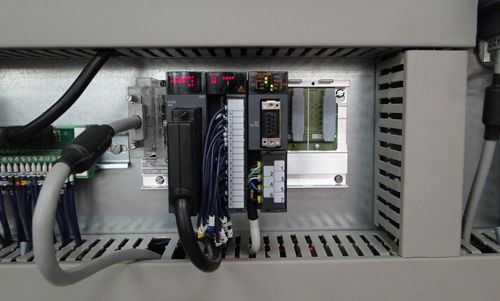

Each of these is driven by a Mitsubishi HF-KP73 servo motor and associated MR-J3-70B servo amplifier and co-ordinated by a system Q controllers.

Mitsubishi Electric recognises that servo drive systems are used for many different tasks, from simple repetitive point-to-point programmes of moderate accuracy to fully synchronised multi-axis applications where live data feeds are constantly resetting operational requirements. To this end it offers a wide range of servo options, including its SSCNET bus controller.

The HF-KP73 motors used by WMH, for example, are low inertia units that respond well to rapid changes in speed and are energy efficient. As loads in the quiche project are predictable, small and do not fluctuate much low inertia motors are ideal; high inertia motors tend to be used where speeds and loads fluctuate more.

The MR-J3 servo amplifiers offer motion control performance to a high level of precision and are popular with many machine builders because of their plug and play installation and simple operation. Of the many MR-J3 functions WMH found the advanced vibration suppression system particularly useful considering the quiche filling is liquid, while the advanced real-time auto tuning ensures maximum precision for aligning and positioning the quiches. Also their compact size was useful for the physical build.

The MR-J3 series is available in several versions; the B-variant was specified by WMH because of its capability to handle complex, multi-axis movement sequences and for its communications options which allow it to network with the PLC, sensors and HMI.

The Mitsubishi Electric system Q PLC is a multidisciplinary automation platform that combines all the elements of common automation systems into one compact, integrated, high performance system. It has twin CPUs and a backplane onto which application specific controller modules are easily mounted to build bespoke controllers.

The Q170MCPU used in the quiche project provides combined motion and logic control in a single module. Communications ports, an external encoder interface and high speed registration inputs allowed WMH to develop a dedicated high-performance system in a compact footprint.

Once the row of quiches is aligned with the front of the oven, a lifting plate is lowered and transfers them onto the oven’s conveyor for cooking. This is not a precision motion, so is accomplished using a Mitsubishi FR700 inverter drive. In fact this is one of 10 FR700s on the machine, all of which control non-precision axis. Despite this all the inverters co-ordinate with the servos on the collating section! The inverters are all controlled over a RS-485 network via a QJ71C24N, one of the control modules selected for the PLC.

In operation the collating conveyor currently has to adapt to four different sizes of quiche: four-inch which are formed into rows of 10; six-inch grouped into eights, and large rectangular family-sized quiches which fit four across. However WMH knew that it was essential to build even more flexibility into the conveyor, because the one constant in the food industry is change – it is a certainty that new quiche sizes and shapes will be required on a fairly regular basis and that this will lead to different collating requirements.

“Fortunately, all the Mitsubishi equipment is designed for just this sort of eventuality,” says Matt. “It is a simple task to re-program the conveyor for new requirements. We could even have it swapping between quiches, pies, flans, tarts and pizzas on an hourly basis if required!”

To ensure the simplest, clearest possible operation, WMH have fitted the machine with a Mitsubishi GOT HMI, in this case a GT1665M-VTBA, which communicates with the PLC over an Ethernet connection. The 8.4 inch touch screen is used not only to keep the shopfloor operators informed but also as the local control point for data entry, parameter resetting etc. The HMI also includes VNC – virtual network computing – allowing remote control from say Cornwall.

The programming for the PLC was performed using Mitsubishi’s GX-Works 2, new configuration software that can be used for all Mitsubishi PLCs; for the HMI GT Designer 3 was used, and for the servo it was ME Developer 2E. All of these are part of the Mitsubishi iQ Works Suite. This is designed to drive efficiency into the programming stage of projects by allowing use and reuse of modularised programmes and by being compatible with five different programming languages.

“It is very easy for machine builders to underestimate the time and effort required in programming the control system of a complex installation,” observes Matt. “GX-Works 2 takes a lot of uncertainty out of the process.”

[info] www.mitsubishi-automation.com [/info]