From November 23 to 25, 2021, Nabtesco will be visiting the SPS in Nuremberg and presenting its extensive precision portfolio. The highlights include the innovative servo gearboxes of the Neco® series as well as an update on the project “The most precise robot in the world”.

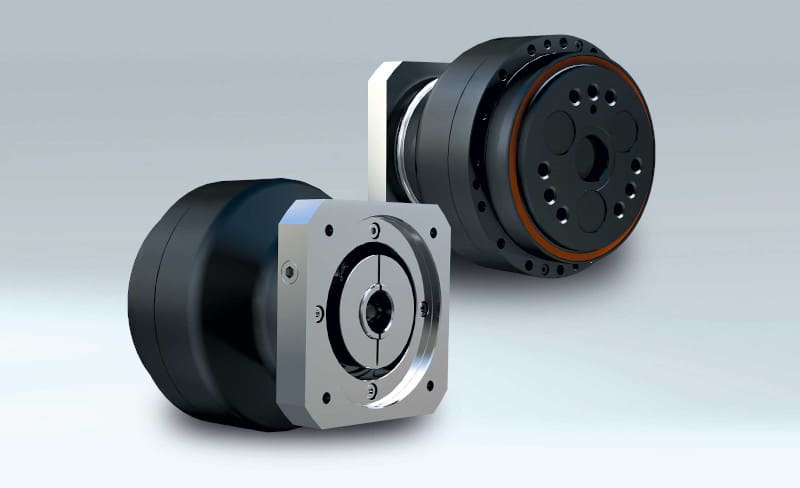

In the early summer of 2020, Nabtesco opened a new chapter in the field of cycloid gears with the Neco® series. The precision gearboxes with solid shafts have been consistently tailored to the needs of customers and set standards in terms of performance, flexibility, user-friendliness, design and economy. Within a very short time, the innovative concept blossomed into a successful model. However, due to the corona, the future-oriented servo gearboxes have not yet been exhibited at any trade fair. Nabtesco is now making up for that. At the SPS 2021, the gear specialist with European headquarters in Düsseldorf will be showing the complete Neco® family with all five sizes (25, 42, 80, 125 and 160) as well as the two available housing shapes (screw connection from the motor or from the application side).

Precise in any size

Under the motto “Precise in any size”, Nabtesco will also be presenting further solutions from its extremely broad portfolio in Hall 3A at Stand 426. Among other things, visitors can look forward to an update on the project “The Most Accurate Robot in the World”. The aim of the cooperation between Nabtesco and the control expert KEBA is to enable customers to manufacture robots with point or path accuracy in the hundredths of a millimeter range.

The integration of condition monitoring into the robot controller based on real serial number-related transmission data is new. This additional function enables an individual snapshot of the robot utilization and thus a consideration of the remaining service life of the transmission. This opens up new, fascinating possibilities for robot, machine and system builders.

“After a long absence from the trade fair, we are very much looking forward to finally being able to meet our customers, business partners and suppliers in person again. We have sorely missed the interaction and direct face-to-face communication at the booth in the past few months. Feel free to come by and find out what advantages cycloid gears can offer your applications, ”invites Daniel Obladen to stop by the Nabtesco stand.

Cycloidal gears offer unbeatable advantages

Whether mechanical engineering, robotics, electromobility, medical technology or intralogistics: Cycloidal gears are the first choice wherever precise positioning and absolute reliability are required. The power transmission via cams and rollers ensures a high degree of efficiency, a long service life and extremely low play (hysteresis loss 0.5 to max. 1 arcmin).

Their special design also leads to excellent behavior in terms of dynamics, resilience and smoothness. Even with large loads or very fast and abrupt movements, the gears ensure precisely executed movements and position with high precision. The integrated angular contact ball bearings absorb axial and radial loads and bending moments and contribute to the high torsional rigidity and resistance to impact and overloading (up to 500% of the nominal torque).