The updated Movotrak™ CTU 7th axis includes collision detection options for innovative programming and control advantages. A new industrial robot transfer unit (RTU) has been introduced, which can seamlessly integrate with a user’s chosen motor and drive.

With a horizontal operating range extending to 10 meters, the Movotrak cobot transfer unit (CTU) distinguishes itself through collision detection that halts the cobot upon encountering an obstacle, enhancing collaboration and boosting productivity.

“By expanding the collaborative features along the 7th axis, manufacturers can utilize cobots to collaborate more effectively and adaptively with humans.” Utilizing the same cobot across multiple workstations enhances productivity and maximizes the return on the initial cobot investment. “We are excited to introduce this revolutionary enhancement to the realm of collaborative robotics,” stated Kyle Thompson, Product Innovation Manager at Thomson.

Transforming Collaborative Robotics

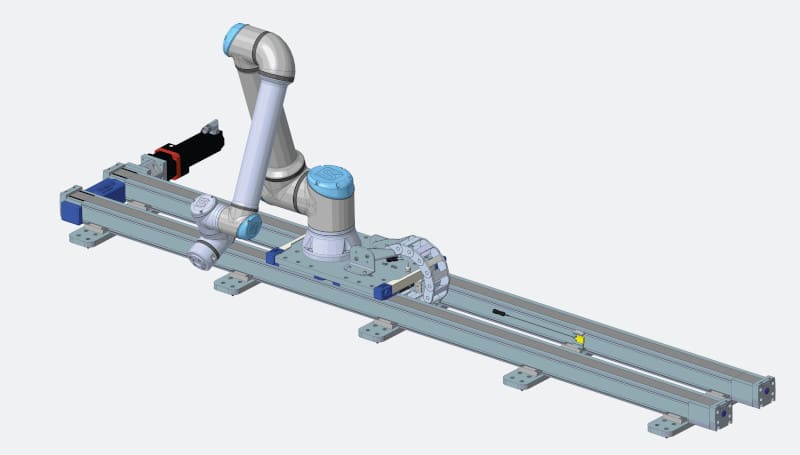

Commonly referred to as a range extender, the Thomson Movotrak CTU 7th axis includes a Kollmorgen servo motor and linear-unit-driven guide rails that transport a cobot assembly between different task locations. Nonetheless, in contrast to all other 7th axes, the Movotrak CTU features collision detection capabilities akin to a cobot joint. During setup, users modify collision sensitivity settings on a control tablet, while the Movotrak CTU motor drive and digital I/O handle collision monitoring and shut down the system.

The collision detection system also monitors current continuously, detecting position errors in the motor, and providing comprehensive anti-collision capabilities along the entire 7th axis. The system includes a small reverse-move feature that eliminates pinch points following a stop.

The Movotrak CTU 7th axis integrates seamlessly with many cobot sizes and brands, including Universal Robots (UR), which allows all programming to be done directly through a URCap interface on their UR Teach Pendant. All collision monitoring and safeguard logic runs in the Thomson drive, so bandwidth competition with the UR controls is minimal.

Easy learning

Similar to the freedrive of cobot joints, the Movotrak CTU 7th axis freedrive functionality enables hand-driven setting of linear waypoints during programming. Users manually slide the cobot where they would like it to be in a sequence along the 7th axis and register that with a simple push button. A good use case example of this feature is an aircraft quality inspector who needs repeated images of the same area over time. Another might be a welder who wants to carry out welding sequences at multiple locations.

Robust and versatile

The Movotrak CTU 7th axis distinguishes itself through its innovative dual-linear unit solution, delivering exceptional moment load capacity and stiffness. This design ensures peak performance, even when fully extending the cobot arm, setting a new standard for reliability. Moreover, it offers unparalleled flexibility. The 7th axis can be seamlessly mounted in a horizontal, inverted or wall-mounted configuration, making it an adaptable choice for diverse applications. Notably, the Movotrak CTU 7th axis is well-equipped for compatibility with even the largest cobots, such as the UR20 and UR30, meeting the specific needs of Thomson customers and responding to the high demand for such configurations.

A quick integration alternative for industrial robots

For those with a preferred servo/auxiliary axis motor and drive, Thomson is also releasing a new industrial RTU, which allows users to quickly and easily equip their robotic applications with a 7th axis. With a Thomson RediMount™ motor mounting adapter kit included, users can integrate their motor in less than a minute and use their own robotic controller to take advantage of the RTU. Compatible with many robot brands and sizes, the industrial RTU features the same dual-linear-unit design and carriage-mounted mounting plate as the Movotrak CTU to ensure optimal precision for your application.

Available immediately, the Thomson Movotrak CTU 7th axis ships as a kit, including the linear units, gearhead, motor, drives, control box, software, end-of-stroke limit switches and cable management. The Thomson industrial RTU is also available and includes dual linear units, gearhead, motor mounting adapter kit, mounting plate, end-of-stroke limit switches and cable management.