Heinen Freezing uses planetary gear units from SEW EURODRIVE in its spiral freezers. This means the customer benefits from the drive manufacturer’s modular system, complete solutions from a single source and extensive service network.

Heinen Freezing GmbH & Co. KG in Varel near Wilhelmshaven has worked in partnership with the food industry for 40 years as a system manufacturer for industrial processing and product preservation. The company supplies high-quality standard models and customized solutions – from individual machines to complex lines. Customers always receive top-notch, high-quality technology. The high-performance, robust drive technology from SEW EURODRIVE plays a part in this.

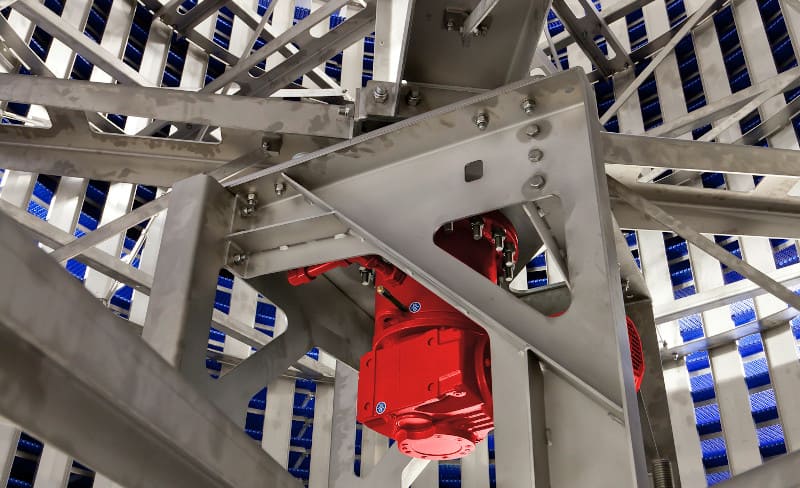

Heinen Freezing uses large series P industrial planetary gear units in spiral systems for continuous pasteurization, proofing, cooling or freezing. The most important property is the combination of extremely high torque and compact installation dimensions. The wide temperature range that the gear units are exposed to presents another particular challenge. This range extends from -35 °C during operation to +40 °C during the cleaning of the spiral freezers.

The SEW EURODRIVE planetary gear units are fitted with reinforced bearings and their output shaft is connected to the input shaft of the conveying system to transfer the high torques via a multi-cone coupling developed in-house. In this setup, the gear unit serves as the lower bearing point of the conveying system shaft. It is exposed to heavy mechanical strain due to the changing load on the conveyor belt and input shafts, which can be up to six meters in height.

To meet the requirements of the food industry, the manufacturer builds a shared oil chamber for the planetary gear unit and the preliminary stage helical-bevel gear unit. As a result, the food grade H1 lubricant designed by SEW EURODRIVE can easily be emptied completely. Furthermore, the Bruchsal-based drive specialist tailors the planetary gear units to the food industry’s needs by applying robust coatings that do not flake off.