At the world’s largest exhibition for the sheet metal working industry, being held in Hanover from 23 to 27 October, Panasonic Robot and Welding Systems is showing in Hall 13 at Booth C07 an expanded product portfolio. With its new handling robots of the HS-G3 Series in combination with Panasonic welding robots, the three robot and welding systems with integrated welding power source: TAWERS Weld Navigation, TAWERS Active Wire Process and TAWERS TIG the company is presenting “All from One”-solutions in the field of robot and welding applications.

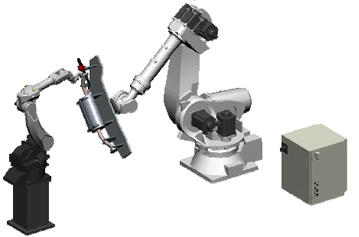

Panasonic Robot and Welding Systems Europe is proud to announce the release of the range of handling robots: HS-G3 series provides an additional field of application capabilities within the existing robot product range. Offering payload capacities of up to 200 kg and a maximum working range of 2.66m. The HS-165 /-200 G3 provides enhanced benefits for production automation solutions requiring work handling.

Used in combination with a Panasonic welding robot, the movements of both robots can be fully synchronized using the “Harmonizer Function”. This feature ensures the relative welding torch position to the work piece is maintained automatically. The programming of the weld position becomes as easy as working with a fixed work piece, ensuring that outof-position welding can be avoided.

Programming and operation takes place by using the G3 controller and the light weight teach panel – exactly matching the control method of the G3 Panasonic welding robots. This G3 controller has a 600% faster main processor than the previous G2 controller, ensuring the acceleration and deceleration processes occur 10% faster than the previous model. The G3 teach panel weighs less than 1 kg and has an improved LCD screen. An additional benefit of the new HS-G3 robots is their flexible adjustment to different workingprocesses. The new Panasonic handling robots will allow both loading and unloading work pieces automatically, helping the realisation of both faster and improved cost-effective production.

Panasonic now offer a comprehensive range of robots for both the welding and handling of work pieces. Production systems and automated lines can now be provided with the innovative TAWERS welding technology and Panasonic handling robots, utilizing just one controller type for all applications.

[info] www.panasonicrobotics.eu [/info]