The Engineered Materials Group (EMG) of Parker Hannifin Corporation, the global leader in motion and control technologies, will be showcasing a wide range of products for electric mobility at EV Tech Expo Europe at Messe Stuttgart (Hall 10, Booth C30), from June 28 to June 30, 2022.

The products to be featured by Parker EMG’s LORD, Prädifa and Chomerics divisions specifically address the exacting requirements of fully electric (EV) and hybrid electric vehicles (HEV) in the areas of:

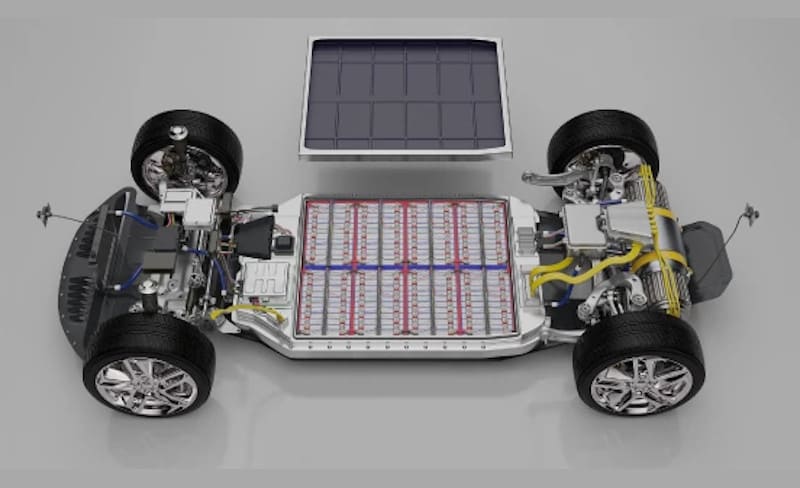

Energy Storage Systems

A wide variety of materials and product solutions are used in energy storage/battery systems for EV and HEV. Parker offers a wide range of sealing solutions for housings, cooling system connections, cable-feed throughs, battery mounts and vents, and maintenance hatches. They ensure reliable protection of moisture-, dirt- and dust-sensitive lithium-ion batteries as well as of 48-volt batteries supporting onboard electrical systems.

For direct bonding of battery cells to cooling plates, enabling higher pack energy densities and reduced manufacturing costs, Parker offers the required adhesive product solutions. They deliver strong adhesion, substantial thermal conductivity, low density, improved flow characteristics, and low dielectric constant.

Energy Converters/Electric Motors

An extensive product portfolio for e-axles in fully electric vehicles encompasses tailored materials and system-integrated sealing solutions for housings and cooling units. Examples of applications include xC housings (i.e., integrated sealing and EMI shielding, and thermally conductive components), cooling connections, drive shafts, and plug connections.

Power Electronics

Sealing solutions for power electronics of electric vehicles range from simple housing seals to dimensionally stable composite solutions, covers with integrated seals, EMI shielding, and heat-dissipating components. They are used in inverters, DC/DC converters, plug connections, cooling connections, and xC housings.

For all heat transfer applications between electronic components and heat sinks Parker offers thermal pad and gap filler solutions ensuring complete conformability (with low clamping forces) and lowest outgassing and providing an effective thermal interface wherever surface irregularities, air gaps, or rough textures are prevalent.

Transmission/Clutch Systems

For the specific requirements of EV transmissions, a wide range of radial shaft seals from elastomers or PTFE compounds is designed for performance across a wide motor speed range with higher rotational speeds. The range of products for HEV clutch systems ensures the requisite reliable and robust sealing performance and extends from wipers to rod, piston, and static seals.

Thermal Management

As a leader in thermal management materials, Parker offers customizable products that help achieve longer EV range, faster charging and higher reliability by managing heat in batteries, chargers, motors, and power electronics. Parker’s CoolTherm® solution represents the latest advancement in thermal management and infuses high-performance thermal interface materials. The product portfolio includes gap fillers and pads, thermally conductive structural adhesives, potting and insulation materials, and materials for semiconductor packaging.

The extensive product portfolio for sealing EV thermal management cooling circuits includes O-rings, flat, and housing seals as well as multi-component parts such as seals with integrated temperature sensors for compact designs. They are produced from tailored materials exhibiting very good temperature stability and compatibility with media such as water-glycol and dielectric dip cooling media such as Novec.

Technology Highlights for Electric Mobility Applications

Sealing Technology

Press-in-Place seals for optimum sealing of housings and prevention of micro leakage.

ParFab and Keyhole ParFab seals specifically for reliable sealing of larger housings.

Warp seals for compensation of tolerances in various axial directions.

The CliPHvent pressure relief valve keeps environmental media from entering the housing and makes it possible for a surge of overpressure being released from the housing to the environment.

Composite technology (bonding of elastomer to plastic or metal parts) for multi-component seals with an expanded scope of functional features, reducing the number of required parts and assembly requirements, and resulting in related cost savings.

Adhesive Technology & Thermal Management

CoolTherm® Cell-to-Pack (CTP) adhesive technologies, including a new TC urethane adhesive, offering strong adhesion, substantial thermal conductivity, low density, improved flow characteristics, and low dielectric constant, for direct bonding of battery cells to cooling plates, enabling higher pack energy densities and reduced manufacturing costs. One-component and two-component variants are available.

THERM-A-GAPTM PAD 30 and 60 for all heat transfer applications between electronic components and heat sinks ensuring complete conformability (with low clamping forces) and lowest outgassing, providing an effective thermal interface wherever uneven surface irregularities, air gaps, or rough textures are prevalent. Typical applications include electronic control units (ECUs) and battery management units (BMUs) as well as vibration-damping applications.