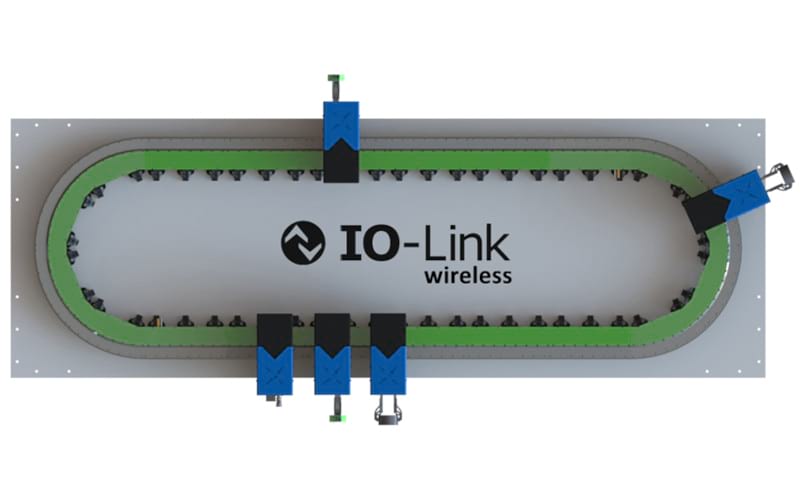

PROTION and CoreTigo are cooperating to develop innovative and unique transport track systems. PROTIONS’s new Orboter solution is based on CoreTigo’s IO-Link Wireless technology and products. The Orboter was developed to drive capacity and flexibility to their maximum and enable adaptive manufacturing for various industrial fields, such as food & beverage, automotive, material handling and packaging.

The collaboration between PROTION and CoreTigo is a result of an increasing need in factory automation for enabling real time communication, data collection and smart applications on independent mover transport track systems. Typically, the movers on these systems neither support energy supply nor data communication for real-time control of actuators on the movers, nor can they communicate sensor data reliably from the movers. This is simply not feasible to achieve with cables on these fast-moving transport systems.

A robust and reliable wireless communication on each mover is required.

The new Orboter solution combined with IO-Link Wireless communication is the perfect answer. It can be deployed on standard transport track systems in the market. The Orboter is equipped with numerous ProBots, which are the smart independent movers of the Orboter that handle parts or objects while in motion. ProBots can manipulate objects with a variety of tools, such a grippers and suction cups. The ProBots can all have the same function or each ProBot can have a different function. Depending on the application, ProBots can collect multiple objects and parts, assemble products, detect objects, determine their position or measure parts.

CoreTigo’s IO-Link Wireless technology enables the communication with the actuators on the ProBots. Products are processed while in constant motion in the most agile and synchronized manner. The built-in IO-Link Wireless communication is designed to ensure low latency (5msec), cable-grade reliability (6 orders of magnitude more reliable than other conventional wireless technologies), real-time control, a synchronized system (micro-seconds), deterministic behavior and scalability to support communication on 100’s of ProBots within a single machine area.

The Orboter with IO-Link Wireless communication brings processes, such as packaging, to a new level of speed. Changeover and setup times are eliminated or carried out parallel to production. It enables manufacturing facilities maximum machine flexibility to support a variety of products, increased production capacity and predictive maintenance. Furthermore, less mechanical components are needed outside the movers, which reduces machine footprint and maintenance. All these are driving adaptive manufacturing even further by enabling small batches at high capacity with maximum production line flexibility to handle different product types and configurations.