Rollon’s linear technology portfolio is one of the most extensive on the market and forms the basis for efficient and reliable automation concepts. At SPS 2024, the group of companies will present its wide range of products, its extensive system solution expertise and its latest innovations. The trade fair highlights include the new H-Bot gantry system, the extremely compact TLS Telescopic System and the AXNR oval system.

Automation without linear technology? Unthinkable. 99 percent of all automation systems contain linear axes, linear guides and/or telescopic rails. High-quality components, innovative solutions and economical concepts are a must and increase competitiveness. As one of the world’s leading suppliers of linear drive technology, Rollon knows the customers’ requirements precisely and implements effective linear technology solutions for a wide range of applications in industrial automation. The group of companies brings together the established brands Rollon, Nadella, Shuton-Ipiranga, Durbal, Chiavette Unificate and Rosa Sistemi under one roof, thus offering unique development, manufacturing and application know-how. Visitors to the SPS 2024 in Nuremberg can also see this for themselves. Rollon will be on site from November 12th to 14th (Hall 3, Stand 321) and will present its comprehensive range of services.

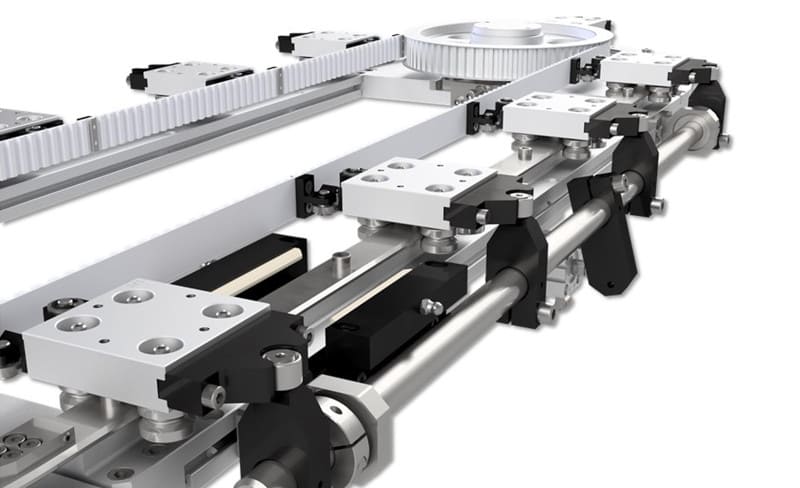

NEW: H-Bot – Innovative gantry system with extreme versatility

Rollon has developed the new H-Bot system specifically for applications that require precision and reliability in confined spaces. It is characterized by an innovative design with a single belt concept and double motor on the X-axis and ensures coordinated and precise movements in a very compact design. By omitting a motor on the Y-axis, the moving masses are significantly reduced, which reduces vibrations and enables high dynamics. The linear axes with toothed belt drive and recirculating ball guides achieve a maximum stroke of 2,500 mm on the X-axis and 1,500 mm on the Y-axis. Speeds of up to 5 m/s and accelerations of up to 50 m/s² with a repeatability of ±0.1 mm are possible in both axis directions. The H-Bot is particularly suitable for handling loads of up to 10 kg – for example in the pharmaceutical industry, the food industry, laboratory automation, 3D printing and assembly, sorting and transfer processes.

Telescopic System TLS: Maximum productivity, minimal space requirement

The telescopic linear axis system TLS is a 2- and 3-stage solution for automation in confined spaces. The use of cost-effective extruded aluminum profiles in conjunction with highly rigid recirculating ball bearing guides and rack and pinion drives achieves optimal performance with high cost-effectiveness. The TLS system is suitable for both vertical installation (limited ceiling height) and horizontal installation (limited lateral installation space) and achieves strokes of up to 3,000 mm and loads of up to 450 kg. Versions with a stroke on both sides are also available. The Telescopic System is an ideal solution for applications in which the travel path of the axis exceeds the distance between the machine and the ceiling or wall. It is versatile, including for machine loading or assembly automation, and can be seamlessly integrated into configurations with multiple axes.

Oval system AXNR: An ideal solution for circular applications

With the Oval system AXNR from the Nadella brand, the company also has a flexible and adaptable system for precise circular applications in its trade fair portfolio. The round rail system is characterized by a high load-bearing capacity, rigidity and precision and realizes smooth, quiet movements and precise positioning. A base made of aluminum alloy and directly connected to the gearbox ensures that space is kept to a minimum and the modular design makes it possible to implement customer-specific modifications and special designs within a very short time.

You can find Rollon at SPS 2024 in Hall 3 at Stand 321.