Linear technology forms the basis of modern storage and conveyor systems and is therefore of essential importance for the implementation of automated processes in intralogistics. Rollon will show how linear technology solutions and an expanded product portfolio help to achieve cost reductions and increases in productivity at LogiMAT in Stuttgart from March 19 to 21, 2024.

As a specialist in linear motion systems and a long-standing partner in intralogistics, Rollon offers a comprehensive portfolio for the automation of the internal flow of goods. In 2023, this was significantly expanded in the area of components and actuators through the merger with Nadella. Since then, customers have benefited from an expanded range of products and services, a broader range of applications and a denser sales, manufacturing, support and service network. At LogiMAT 2024 in Stuttgart, the company will be presenting, among other things, its wide range of services for warehouse automation, an efficient, integrated telescopic rail solution for shuttle systems, an innovative oval system for circular applications as well as ball screws, rod ends and spherical plain bearings.

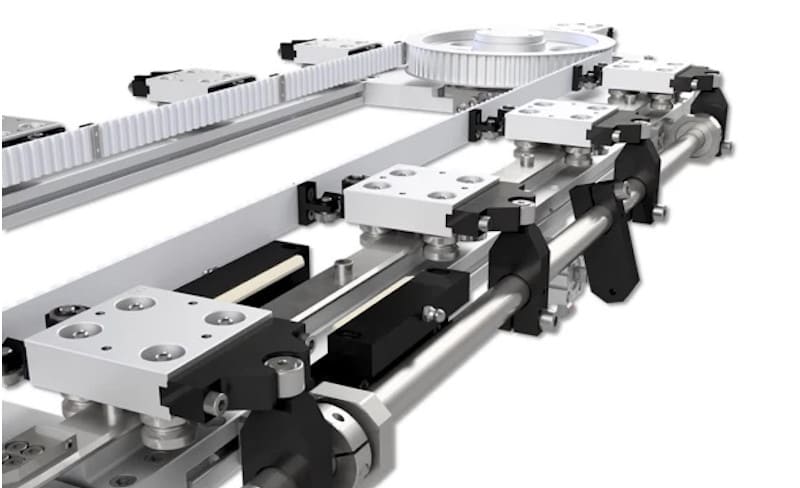

Efficient, integrated telescopic rail solution for shuttle systems

Based on the Telescopic Rail , Rollon has developed an efficient and integrated linear technology solution that offers manufacturers of shuttle systems enormous time savings. The modular system with telescopic rails, rack and pulleys is pre-configured, pre-assembled at the factory and easy to integrate. A demo model with two ASN partial excerpts illustrates what this looks like in practice. The linear guide system ensures smooth and consistent running and is an efficient solution for shuttles, miniloads and mobile robots in automated warehouses.

Oval system AXNR: powerful, compact, flexible

With the oval system AXNR from the Nadella brand, the company also has a flexible and adaptable system for precise circular applications in its trade fair portfolio. The round rail system is characterized by a high load capacity, rigidity and precision and realizes uniform, quiet movements and precise positioning. A base machined from an aluminum alloy and connected directly to the gearbox

ensures a small space requirement and the modular design makes it possible to implement customer-specific modifications and special designs within a very short time.

Diverse product portfolio for intralogistics

Whether automated shuttles, storage and retrieval machines (RBG), automated guided vehicle systems (AGV), tower/shuttle systems or packaging and palletizer applications: The company’s diverse portfolio ranges from linear guides, telescopic rails and linear axes to ball screws through to rod ends and spherical plain bearings and almost covers everything all requirements. The result is flexible, user-friendly and economical automation concepts with the highest level of precision, dynamics and reliability.

You can find Rollon at LogiMAT 2024 in Hall 5 at Stand 5D05.