Achieve industry-leading cycle time with an arm length of 1,200 mm and a maximum payload of 50 kg

Yamaha Motor Europe announced today that it will expand the YK1200XG model of the SCARA robot YK-XG series and release it in October this year along with the dedicated controller RCX341.

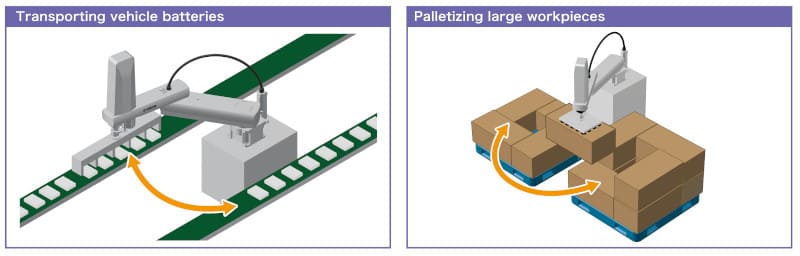

The YK1200XG is a SCARA robot designed for the assembly and transportation of large, heavy objects. With an arm length of 1,200 mm and a maximum payload of 50 kg, it achieves industry-leading cycle times.

The dedicated controller “RCX341” maintains the compact design of the conventional “RCX340” model, but increases the maximum output current, providing stable support for high-speed transportation of heavy objects by the YK1200XG.

The SCARA robot YK-XG series has a completely beltless structure that significantly reduces motion loss and achieves high precision over a long period of time. In addition, since the tip rotating shaft and the reducer are directly connected, the allowable inertia of the R axis is large, making it possible to operate at high speed even with offset work. With the addition of the YK1200XG, the product lineup now has a wide range of arm lengths from 120 mm to 1,200 mm, making it one of the best in the industry.

Market Background

Yamaha Motor is a comprehensive supplier of small robot systems, offering a wide range of products including linear conveyors, single-axis robots, SCARA robots, vision systems, and controllers for automated production lines. The company strives to provide optimal solutions to the diverse needs of its customers by leveraging its extensive product range to improve efficiency and quality in increasingly complex, diverse, and fast-paced production environments.

In particular, since starting to manufacture and sell SCARA robots in 1984, the company has been working to achieve both low prices and high-speed, high-precision performance, and is working to popularize robot products in a market with a highly competitive environment. The YK1200XG is designed to meet the growing global demand for automotive battery manufacturing processes due to the rise of electric mobility. It combines high operational performance with cost-effectiveness, making it ideal for handling weights of 20 to 50 kg, the range most commonly used in automotive battery manufacturing and assembly transport lines.

Main features of the SCARA YK1200XG

High speed

The YK1200XG has an arm length of 1,200 mm and a maximum payload capacity of 50 kg, achieving the industry’s fastest standard cycle time* for a SCARA robot. In addition to this standard cycle time, Yamaha Motor also places importance on cycle times in practical applications. By checking the gear ratio and maximum engine speed, Yamaha Motor has significantly improved the maximum speed compared to the previous model. In addition, because the tip rotating shaft and the reducer are directly connected, the R-axis allowable moment of inertia is significantly higher than in general structures that use a reducer and belt, making it possible to operate at high speeds even with offset workpieces.

*Based on a SCARA robot arm length of 1,200 mm. Yamaha Motor data as of September 2024. Standard cycle time: 0.92 seconds (with a payload of 40 kg).

Internal structure that achieves high rigidity

The direct connection structure of the ZR axle enables a completely beltless design. The beltless structure significantly reduces rattling. It can be used for a long time without maintenance, so there is no need to worry about belt damage, stretching, or deterioration over time.

Main features of RCX341

Compact design and high performance

Based on the “RCX340”, which is known for its high functionality that enables advanced system construction, the internal structure of the controller and inverter circuit has been revised. The case size remains the same at W355mm x H195mm x D130mm, but the maximum output current has been increased. Supports quick handling of heavy objects. The regenerative unit is also designed to match the height and depth of the controller (W80mm x H195mm x D130mm), and can also be installed inside the control panel.