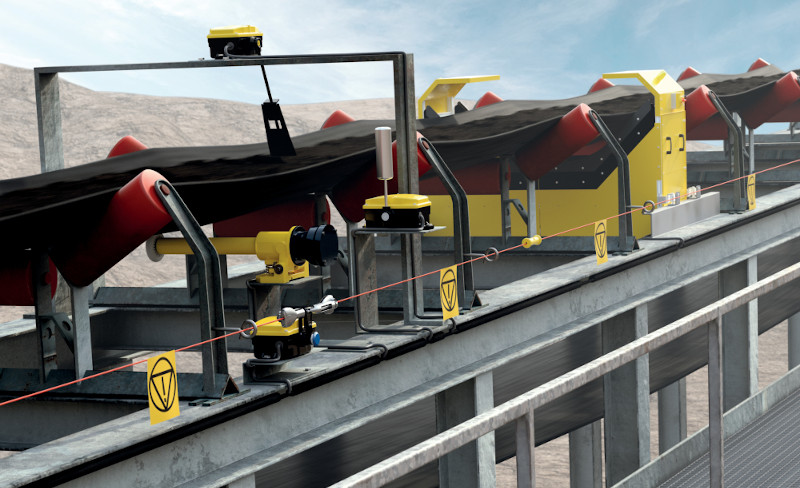

The Schmersal Group will use SOLIDS 2022 to showcase a number of innovative systems for safe and efficient design of bulky goods conveyors using a demo conveyor system. One particular solution will be Schmersal’s option for condition monitoring – the capture and evaluation of process and diagnosis data from system components to enable predictive maintenance, to increase availability and to ensure the conveyor system’s efficient operation.

The HX270, a new online monitoring system for conveyors from Schmersal’s system partner ROXON, will be on display at stand K22 in hall 5.

Systems for machine and personal protection

Schmersal’s systems help to safeguard the safety of people and processes, and in some cases with just a single device. The modular HDS series offers a number of functions in a single device platform – an emergency stop as an emergency pull-wire, and belt misalignment monitoring, which constitutes a key element in conveyor system process protection.

Switches in the HDS series can be optionally connected to the Dupline installation bus allowing them to be connected in series and thus enabling better transmission of diagnosis data. The transmission of status information allows anomalies to be identified and faults to be rectified more quickly, in turn reducing downtime. Schmersal is currently testing a prototype HDS switch with integrated wireless element for the wireless transmission of status information over large distances.

Systems for plant and investment protection

Conveyor belt monitoring systems help to boost the availability of a system. In additional to proprietary components and systems designed to boost machine safety, Schmersal is now able to offer an online monitoring system for existing or new conveyor systems through its system partner ROXON. The HX270 enables optical 3D belt surface sampling in real time both for the material side and running side of the conveyor belt.

With high-speed precision scanning using novel 3D image analysis algorithms, the system can detect any change or damage to the belt surface fully automatically, 24 hours a day. In addition, optional belt thickness measurement gives the system a full-fledged condition monitoring solution for smart maintenance and servicing. This helps to lower process costs and the costs incurred during production downtime.

Systems for material and quality monitoring

The elementary composition of bulky goods can be determined online and in real time while on the conveyor belt on the basis of a PGNAA analysis. This measuring process helps the coal, cement, mineral and steel industries to sustainably improve their processes and overall quality assurance.

Visit Schmersal at SOLIDS 2022 in Dortmund (Germany) on 22 and 23 June 2022: Stand K 22, Hall 5