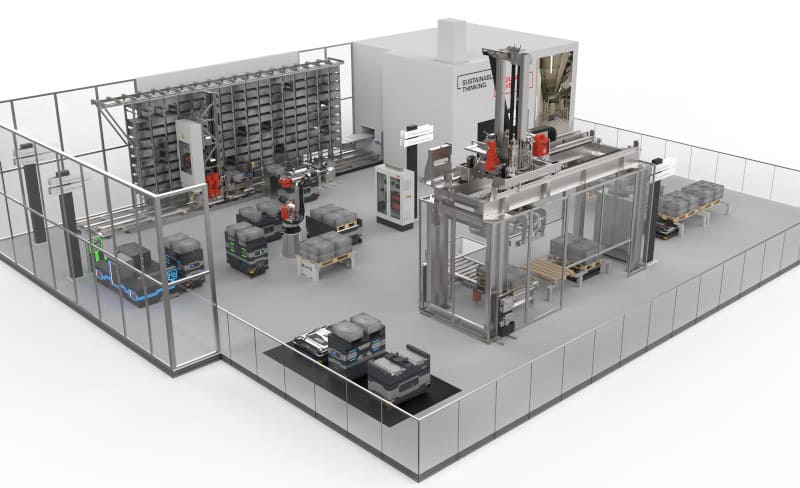

In line with the lead theme of HANNOVER MESSE – “Energizing a sustainable industry” – SEW-EURODRIVE is exhibiting at this year’s trade show under the slogan “Sustainable thinking. Modular drive.” This drive and automation technology specialist offers efficient, customized solutions based on its modular concept to help customers reduce their own carbon footprints, depending on the industrial sector and application in question. The Bruchsal-based company will be demonstrating exactly how this works at its stand that extends across some 1700 square meters – Stand B26 in Hall 6. A particular highlight awaiting visitors is a practical example based on the company’s collaboration with the Knauf Group demonstrating how innovative drive technologies will make it possible to produce construction materials more efficiently and sustainably in the future.

The combination of international climate protection agreements, the decision in Germany to bring forward certain climate-related target dates, and new legal regulations means that sustainability and environmental protection are now part and parcel of every industrial company’s performance specifications. Priorities include conserving resources of all kinds and becoming energy self-sufficient. In the industrial sector, construction materials manufacturers are among the companies that have particularly high needs in terms of energy and resources. This industry is therefore under a huge amount of pressure to reach the climate targets that have been set. One not insignificant factor at play in the consumption of resources and energy in this sector relates to the electric drive technology and associated accessories that are used.

“In the construction materials production sector, hardly any drives operate in 24-hour continuous duty with an unchanging load – in other words, under the conditions that allow our most energy-efficient drive systems to deliver their sustainability benefits,” explains Patrik Menges, head of SEW–EURODRIVE Germany. He is in no doubt about what this means: “If we, as a drive and automation specialist, are to be able to offer sustainable application solutions in this sector, we need to be particularly innovative.” Thomas Krämer, Managing Director of Technology and board member at Knauf, adds: “For us, this is an important reason why we have been working with SEW-EURODRIVE for some time now to consider how we can become even more sustainable in this sector.”

SEW-EURODRIVE has therefore taken the slogan of this year’s HANNOVER MESSE as an opportunity to showcase at its stand – with support from Knauf – solutions that demonstrate how this specific industrial sector can make itself fit for the future. The company is showcasing sustainable technologies and measures specifically geared toward saving resources at a series of stations that vividly map out an entire gypsum production process from the mining of raw materials in quarries to the logistics in the outgoing goods section. These technologies and measures include, for example, reducing the amount of oil a gear unit needs by up to 30 percent, using digital twins for the precise design and dimensioning of a drive, segmented girth gears that allow for a partial retrofit, and using intelligent condition monitoring to sustainably reduce down-time to a minimum.

ECO2 gearmotors without a coating are an option

The company is also exhibiting other solutions at HANNOVER MESSE that fit perfectly with the theme of sustainability. With the ECO2 design for gear-motors, for instance, users can conserve valuable resources while also cutting costs. This is because drives in aluminum housings are also available without any coating or painting, which is perfectly suitable for applications that are in enclosed spaces and are well protected from heat, cold, and moisture. When working in these conditions, the energy-intensive coating and painting process can be completely eliminated, especially since aluminum is not susceptible to corrosion. Another advantage of this is that the coating-free components – unlike painted gear unit housings – can be recycled later in a much easier and much more environmentally friendly manner. What’s more, they don’t need to be recoated after repairs, so another energy-intensive process is avoided.

Energy-efficient IE5 modular motors

The new motors from SEW-EURODRIVE are yet another testament to the company’s commitment to staying one or two steps ahead of the applicable energy efficiency regulations. For example, the DRU.. series of asynchronous motors (line-operated motors) and the DR2C.. series of synchronous motors already meet the highest efficiency class defined by standards for their particular class and design. DRU.. motors offer energy efficiency in line with IE4, with DR2C.. motors and CM3C.. synchronous servomotors even achieving IE5. A particular added benefit of the modular principle is that almost all options and accessories in the SEW EURODRIVE modular system of motors are available for each of these motors, regardless of whether they are asynchronous or synchronous.

Safe and efficient systems thanks to power and energy management

In addition to highly efficient drives and a green energy supply, drive solutions with intelligent energy management functions are yet another example of pioneering technology. The Power and Energy Solutions from SEW-EURODRIVE ensure that energy present in the system is kept in the system. This is an innovative way of enabling users to utilize energy more intelligently while also reducing energy consumption from the public grid.

Decentralized technology for greater flexibility and efficiency in production

In the area of decentralized technology, too, systems can be designed to use less energy. For example, the MOVIMOT® performance ELV extra-low voltage drives offer a very high level of efficiency thanks to their compact design and DC energy recovery. Besides featuring an integrated decentralized inverter, the MOVIMOT® advanced drive unit can be fitted with either an IE3 asynchronous motor from the DRN.. series or an IE5 synchronous motor from the DR2C.. series, and can be adapted to suit the efficiency requirements of the specific customer application.

Condition monitoring with the DriveRadar® IoT Suite

The DriveRadar® IoT Suite from SEW EURODRIVE is yet another solution that boosts efficiency. Since system operators can use this condition monitoring system to reliably predict the behavior of their drives and system components, they can plan maintenance and repairs in advance and use their drives more efficiently.

Experience efficiency in a fun, interactive way

At SEW-EURODRIVE, it’s all about using less and less energy more and more effectively. Visitors to HANNOVER MESSE can have fun experiencing this for themselves. For example, the AI in a pick-and-place model ensures that the integrated robot can perfect the task it is required to perform. With this interactive exhibit, visitors can wipe the robot’s memory and watch it learning everything from scratch once more. Visitors can also interact with a didactics-related innovation in the form of a new app that is adding augmented reality to the teaching aids for gear technology. Users simply put on a HoloLens head-set and can then assemble a gear unit themselves with the help of visual overlays and spoken instructions.