With the launch of MOVIMOT® performance ELV, SEW-EURODRIVE is adding network-capable designs to its range of decentralized compact extra-low voltage drives with a 48V DC power supply. Using drives with Ethernet-based communication interfaces enables users to implement highly flexible process control and systematic material flow monitoring, particularly in facilities with complex transport systems.

The latest addition to the portfolio fuses together the benefits of compact extra-low voltage gearmotors and the advantages offered by the latest generation of the MOVI-C® communication platform and the MOVISUITE® engineering tool from SEW-EURODRIVE. MOVIMOT® performance ELV combines a permanent-field synchronous motor with a dynamic drive controller and high-performance communication interface. Users can temporarily harness up to 350 percent of the motor’s continuous torque for acceleration procedures or peaks in the material flow. This makes it possible to achieve decentralized drive solutions that exhibit considerable power density and high efficiency.

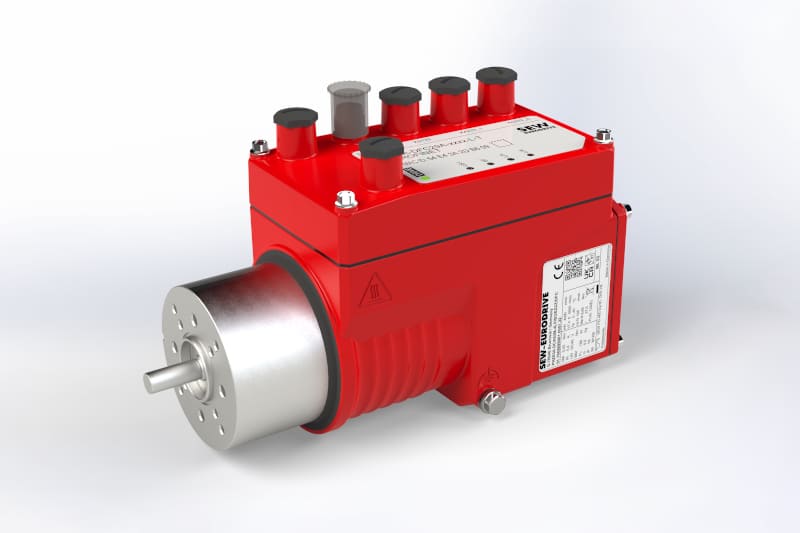

All connections are made consistently via standardized and standard-compliant M12 plug connectors that are coded differently. These ensure installation can be carried out quickly and without errors, even when working under time pressure or difficult on-site conditions. The fully plug-in protective extra-low voltage design eliminates the need for certain installation measures designed to ensure electrical safety and means there are fewer requirements that staff carrying out the work have to meet.

When combined with tried-and-tested planetary, right-angle and parallel-shaft helical gear units from SEW-EURODRIVE’s modular system, MOVIMOT® performance ELV gives users flexibility and enables them to plan projects in line with needs when integrating the drive into the relevant application or system. The drives are available with a choice of PROFINET, Ethernet or EtherCAT® interface. They enable users to establish horizontal communication between drive modules as well as vertical communication with the system control level. Comprehensive device and system status analyses are supported by the electronic nameplate and the continuous availability of status and load data.

The high-resolution encoder is essential for applications where torque, speed or position are to be controlled. Typical areas of use for the entire drive portfolio include applications in intralogistics and distribution logistics, such as linear and accumulating roller conveyors, rotary units, lifting modules and corner transfer units. SEW-EURODRIVE’s compact extra-low voltage drives are the perfect solution for stationary and mobile storage systems such as conveyor modules, load handling devices, and shuttle travel drives.