This document describes architectures and components in water and wastewater technology as they most commonly appear. The hardware configurations in the example are for illustration. They may differ in real projects.

Description of the automation in a small wastewater treatment plant for 5,000 to 10,000 inhabitants or more. The plant needs to be controllable both through the on-site hardware as well as centrally with a graphical user interface.

Small sewage treatment plants can be economically constructed from innovative energy- and motor-management systems for drives with SIMOCODE pro V PN, ET200SP motor starters up to the 7.5 kW range, soft starters or frequency converters from the SINAMICS G120 X family and SENTRON PAC 3220 devices.

Three possible automation concepts are described below.

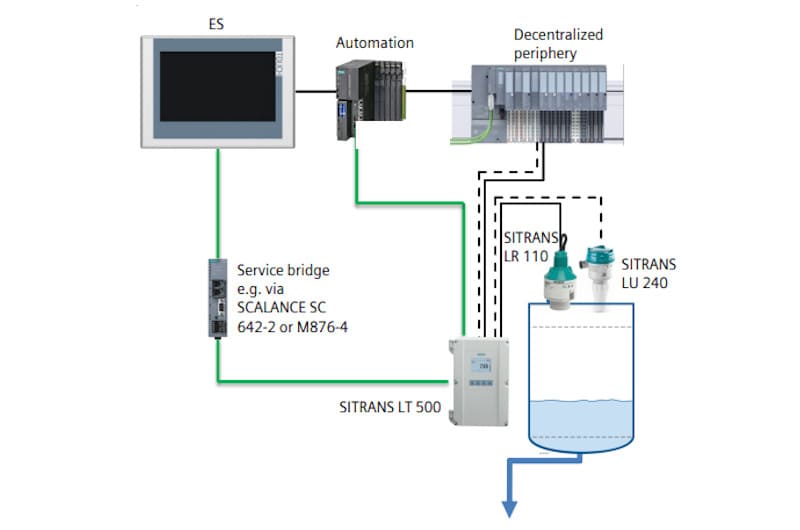

- Concept 1 (page 7) consists of three SIMATIC controllers. All equipment and measurements are linked to the controller via conventional input/output modules. Local monitoring & control (M&C) in this concept is effected with a TIA Portal-based Comfort Panel.

- Concept 2 (page 10) consists of a SIMATIC soft PLC (WinAC). Wherever possible, all equipment and measurements are linked to the controller via PROFIBUS DP. Local monitoring & control (M&C) in this concept is effected with WinCC Unified, based on TIA Portal.

- Concept 3 (page 13) is designed as a full-fledged SIMATIC PCS 7/PCS neo process control solution. The majority of the equipment is connected via PROFINET to the central 410-5E SIMATIC CPU. The non-PROFINET-capable instruments are connected via conventional AI/AO modules (4…20 mA). Local monitoring & control (M&C) is effected with an ES/OS single station in PCS 7/PCS neo.