Whether in the electrical and electronics industry, especially in automotive or general mechanical engineering or in other material processing: Modern solutions are making automation more and more digital, smarter – and at the same time more energy-efficient. The specialist for electrical and pneumatic automation will show why SMC is no exception here from November 8 to 10, 2022 at the leading trade fair smart production solutions (sps) in Nuremberg. These include precise and robust electric drives, fieldbus systems for extensive communication and a plug-and-use solution for energy transparency, which SMC will be presenting at the leading trade fair for smart and digital automation.

After a two-year break, the leading trade fair smart production solutions (sps) is opening its doors again this year in Nuremberg. The leading manufacturer, partner and solution provider for pneumatic and electrical automation technology SMC will also be there, presenting exciting new solutions from its extensive product portfolio in Hall 4, Stand 371. Among the highlights are the high-precision electric drive of the LEKFS series and the electric drive of the LEY-X8 series, which is particularly suitable for harsh environments, the wireless fieldbus system of the EX600-W series and the fieldbus system of the EX260-FPS1 series, which ensures high machine safety and finally the plug-and-use solution EnergieTransparenz@SMC, which is installed and ready to use in just a few minutes.

Move precisely under all conditions

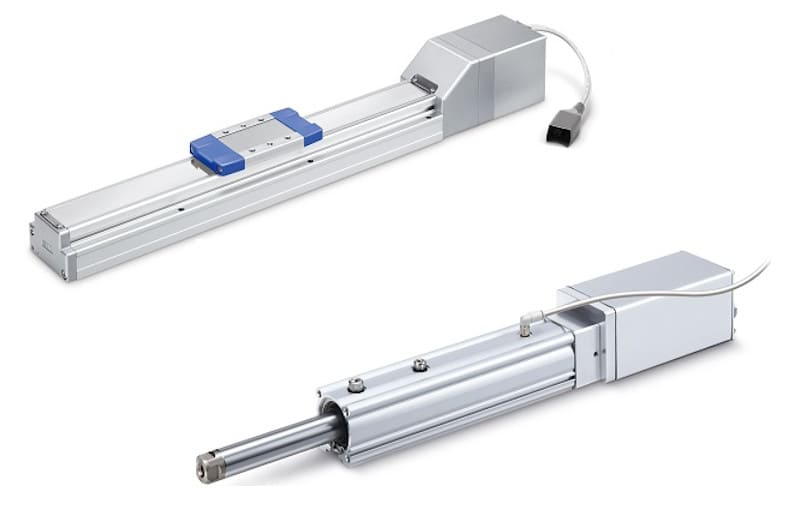

Whether for pushing or pulling movements or general transport systems: Electric drives have become indispensable across all industries. In order to be well equipped for particularly precise tasks that require a high level of safety, SMC is presenting the LEKFS series at the trade fair. In addition to a positioning accuracy of ±0.01 mm, the smart construction has a high level of rigidity, which means that the deviation in slide play is 0 mm for all sizes. In addition, the electric drive is extensively compatible with all common communication protocols (including EtherCAT, EtherNet/IP, PROFINET, IO-Link) and the version with a 24 DC stepper motor can also be ordered with a battery-free absolute encoder.

For applications that take place under adverse conditions such as dusty environments up to temporary submersion in water, SMC will present the electric drives of the LEY-X8 series in Hall 4, Stand 371. Because in addition to protection class IP65, they also have protection class IP67, which makes them particularly resistant. While payloads between 12 and 90 kg can be moved in the horizontal direction of movement, they are between 7 and 52 kg in vertical operation. The LEY-X8 series achieves a high precision repeatability of ±0.02 mm and, thanks to a battery-free absolute encoder, can continue operation immediately from the last position without reference travel after a power loss.

Communicate securely and reliably

If tools such as welding tongs or grippers on robot arms are changed frequently, a wireless connection to the units used makes the work much easier. This is also the case with the EX600-W wireless fieldbus system that SMC is presenting in Nuremberg: Thanks to the fast connection establishment (250 ms), tools can be changed in a short time and are ready for use again. By encrypting the transmitted data, resorting to frequency hopping (5 ms – with 79 available channels) and hiding certain channels, a secure and interference-free connection is achieved. The remote modules can be used over a distance of 10 m, which makes them ideal for large automation systems. In addition, they are compatible with the most widespread network protocols EtherNet/IP™ and PROFINET.

With the fieldbus system of the EX260-FPS1 series, SMC is showing another communication solution at the trade fair that can be used to meet particularly high standards in terms of machine safety. With the integrated safety output for the PROFIsafe protocol, not only can a separate safety output unit be dispensed with, but there is also no wiring between the fieldbus module and the safety output device. This saves space and hardware costs – at the same time, the fieldbus module allows users to meet the safety standards ISO 13849-1 PL e (highest performance level) and IEC 61508/IEC 62061 SIL 3 (second highest safety integrity level). This ensures a particularly high level of machine safety.

Good for the wallet – and the climate

The use of compressed air is indispensable for numerous applications in industry and at the same time a real cost factor. Using the plug-and-use solution EnergieTransparenz@SMC, SMC will show at the sps how unnecessary consumption can be identified, for example due to leaks. Consisting of a compact and ready-to-plug assembly and an IoT platform, it is ready for use in less than ten minutes. In this way, users quickly receive an overview of consumption data such as pressure and flow values in real time and can analyze medium and long-term trends in order to prevent unnecessary consumption. This saves costs, reduces CO 2 emissions and the data can be used as a basis for ISO 50001, for example.

Trade visitors will find SMC at sps 2022 in Nuremberg from November 8th to 10th. in Hall 4, Stand 371.