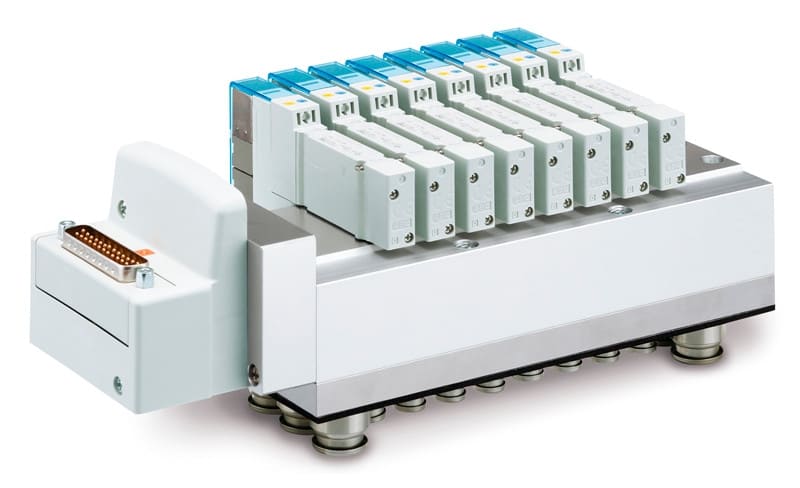

The new JSY3000-S is a bottom-ported manifold with stainless steel plate and FDA-compliant fittings that delivers extended operating life in food and beverage manufacturing environments. Part of SMC’s extensive directional control valve family, the new plug-in JSY3000-S is cabinet-mounted with a robust bottom seal and the piping connections facing outwards. This design configuration helps to protect the valve against both corrosion and splashes from water, ensuring its suitability for location near any type of equipment that requires wash-down procedures.

Wash-downs have a major effect on automated system components such as valves, particularly those lacking the engineering robustness needed to prevent issues such as corrosion. To help extend operating life in these conditions, SMC’s JSY3000-S deploys a corrosion-resistant plate made of stainless steel 304, complemented by one-touch fittings manufactured from stainless steel 316. The fittings are FDA compliant, ensuring their safe use in process industries such as food and beverage.

No flooding

A further requirement of automated systems for food and beverage plants is the ability to protect against the ingress of water and detergents. Poorly protected valves can easily flood, leading to downtime and costly maintenance. In contrast, the JSY3000-S prevents any potential for penetration by water with its robust EPDM bottom seal.

Another key feature is a decorative trim plate. Available as an option, the trim plate delivers a clean look that masks a roughly cut control cabinet. Furthermore, if the wall of the cabinet is thin or the gaskets are non-uniform, the trim plate ensures an adequate seal.

Remote communication

Users of the SMC JSY3000-S benefit from the important ability to communicate remotely. It is possible to control and monitor up to 32 outputs via a wide variety of serial interface communication protocols, including EtherNet/IP, PROFINET, EtherCAT, DeviceNet, PROFIBUS DP and IO-Link.

Both serial and parallel wiring manifolds are available. Users can opt for SMC’s EX serial interface units, with centralised and decentralised solutions, such as the company’s innovative wireless fieldbus system. The wiring can be single wiring or double wiring. For single wiring configurations, the JSY3000-S is available with 8, 12, 16, 20 or 24 valve stations, while double wiring versions offer 8, 12 or 16 valve stations.

Design versatility

The new bottom-ported manifold is lightweight and compact, supporting location in control cabinets with reduced dimensions. Indeed, for a valve of such small size, the JSY3000-S delivers considerable flow rate, ensuring its suitability for use in both mobile and compact applications. As a final point, the valve’s inherent design versatility ensures simple installation with no requirement to mount and seal individual bulkhead connections.

Automated systems for food and beverage plants, or any equipment subject to wash-down procedures, can enjoy extended service life with the new SMC JSY3000-S. The resulting reductions in downtime and maintenance serve to enhance important metrics such as productivity and OEE (overall equipment effectiveness).