STEMMER IMAGING has been an expert in machine vision technology for 35 years. In its anniversary year, the company is now presenting its new embedded vision concept “STEMMER IMAGING Modular Embedded”. Setup as a comprehensive ecosystem, Modular Embedded relies on a powerful hardware selection combined with a wide range of state-of-the-art cameras, the best software tools and individual service packages.

Everything from a single source and with expert knowledge that customers can rely on to realise sophisticated machine vision solutions on modern embedded technology quickly and without major development effort.

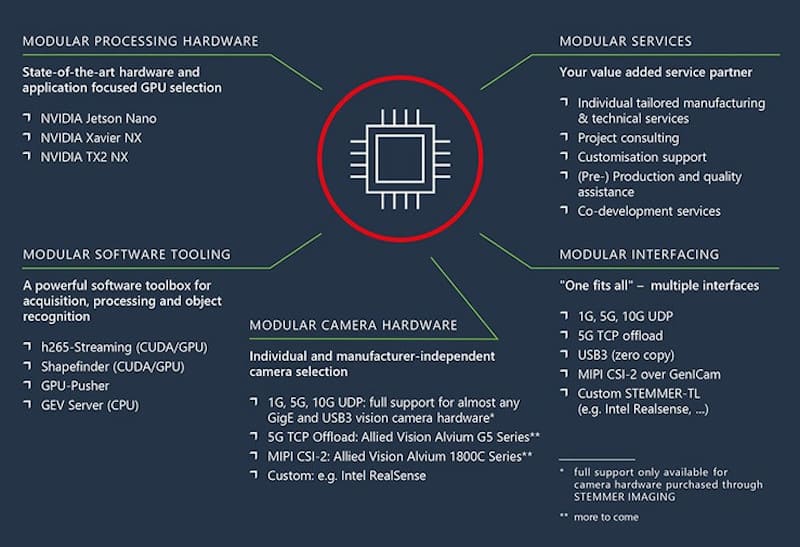

The core of the system is STEMMER IMAGING’s proprietary Modular Embedded Carrier Board coupled with STEMMER IMAGING’s own generic driver stack, both designed for flexible use in vision applications in a wide range of industries.

The board enables manufacturer-independent camera use. It is based on the latest, most powerful NVIDIA Jetson hardware and offers plug and play efficiency for the rapid development of embedded vision and AI projects.

On the software side, Common Vision Blox (CVB), STEMMER IMAGING‘s software library, offers the well-known flexibility and performance for image acquisition and processing. GPU-accelerated algorithms for local preprocessing and data reduction are the perfect foundation for building complex applications with maximum reliability and performance, both in prototyping and series production. TCP offload technology for image capture offloads the processor while enabling the maximum performance to be achieved with a low power consumption.

Full GenICam compatibility opens up a comprehensive selection of cameras for all common interfaces (GigE, USB, MIPI) without the need for special programming skills.

The hardware is ready for immediate use and releases users from customised board developments. Equipped with a decent number of 10GigE, USB3 and MIPI interfaces, the Embedded Ecosystem’s hardware modules are particularly suitable for demanding vision applications supporting a high bandwidth and multiple simultaneous cameras.

Hardware I/O and a separate GigE interface provide communication with an automation controller or a connected host PC. The integrated M2 interface allows access to a wide range of peripheral hardware. Due to its compact design, the board can also be easily used in space-constrained vision systems.

Customers benefit from comprehensive service packages

A comprehensive and flexible range of service packages round off the Modular Embedded Ecosystem and offer customers the best possible opportunity to achieve their project objectives. These range from feasibility studies, assistance to select the right products along with comprehensive support of the technology through product training and consulting services followed up by lifecycle management services. Customers thus benefit from calculatable costs, maximum transparency, receiving an easy-to-use all-in-one solution for their project.

Embedded Vision for all industries and applications

“We want to enable developers to integrate embedded vision into their devices easily, quickly and flexibly by supporting them in the best possible way. Our Modular Embedded Ecosystem is the most flexible offering on the market and is easy to integrate into a wide variety of applications,” says COO Uwe Kemm, describing the advantages of the concept.