When Mercedes-Benz wanted to expand their AGV installation, they called HMS. HMS provided the wireless expertise, products, and hands on support to ensure the AGVs moved efficiently and safely around the factory.

Mercedes-Benz, a globally recognized automotive manufacturer, is renowned for its innovative technology, craftsmanship, and luxury design. At their state-of-the-art automotive factory in Ludwigsfelde, over 70 AGVs move automotive parts to the assembly line. These AGVs transport everything from heavy engines to smaller electronics across distances ranging from 300 to 800 meters. Each AGV is equipped with an on-board Programmable Logic Controller (PLC) from Siemens or Schneider Electric, which ensures their efficient and safe navigation.

Good communication is key

Guiding the AGVs effectively relies on good communication between the AGVs and the factory’s control system. This communication enables the factory to track the AGVs’ whereabouts, cargo, and real-time status.

Mercedes-Benz’s previous AGV system used Bluetooth technology and HMS’ Anybus Wireless Bolt and Anybus Bridge products. However, they wanted to improve the system’s efficiency and be able to comply with the Machinery Regulation (EU) 2023/1230, which becomes mandatory in January 2027. Maximilian Lichan explains: “While Bluetooth worked well, we now want to enhance our AGV system to support higher throughput, fast roaming, and lower latency. We also need to comply with the soon-to-be mandatory EU safety regulations. Equally important, we want the equipment and experts from the same company, and we want them to come onsite, install the equipment, and verify that everything works”.

Time to see how HMS helped implement a wireless system to meet the needs.

HMS wireless experts pave the way

Mercedes-Benz provided key information, such as floorplans, to HMS’ wireless experts. Using this information, HMS first conducted a predictive site survey to determine the optimal placement and number of access points required. HMS then visited the factory to verify the accuracy of the survey and make any necessary adjustments.

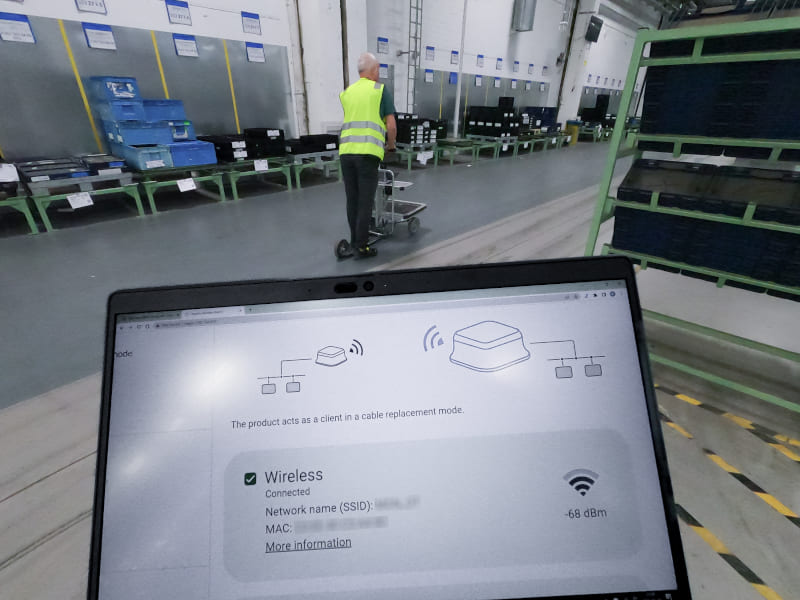

Mercedes-Benz used the updated predictive site survey to install the required power outlets and network cabling. Once the required infrastructure was in place, HMS returned to install and configure the Anybus Wireless products before verifying that the installation worked as planned.

Anybus wireless products

The wireless infrastructure uses Anybus Access Points powered by Anybus PoE L2 Managed Switches, with an Anybus Wireless Bolt II mounted on each AGV. The Anybus Wireless Bolts handle communication from the AGVs to the traffic control system and connect to the 12 different access points in the factory’s ceiling. As an AGV moves out of range of one access point, it transitions to the next, ensuring uninterrupted communication.

The results

With the wireless expertise of HMS and their Anybus Wireless products, Mercedes-Benz successfully achieved its goal of efficient and safe transportation of goods within the factory. Maximilian happily reflects on the outcome:

“Everything worked as we hoped. The connection is very stable, and we are now able to comply with the safety machinery regulation. The support for more bandwidth has even allowed us to manage and configure the AGVs remotely, which, while not a key objective is a nice bonus”.

Finally, what are your tips to users who are thinking of going wireless?

“A key factor for us was that HMS were on hand to design and install the wireless infrastructure. That was important for us. We wanted to have wireless experts onsite to ensure that everything went smoothly. We’re not wireless experts, HMS are. We make cars, which you probably already knew”, Maximilian adds with a smile.