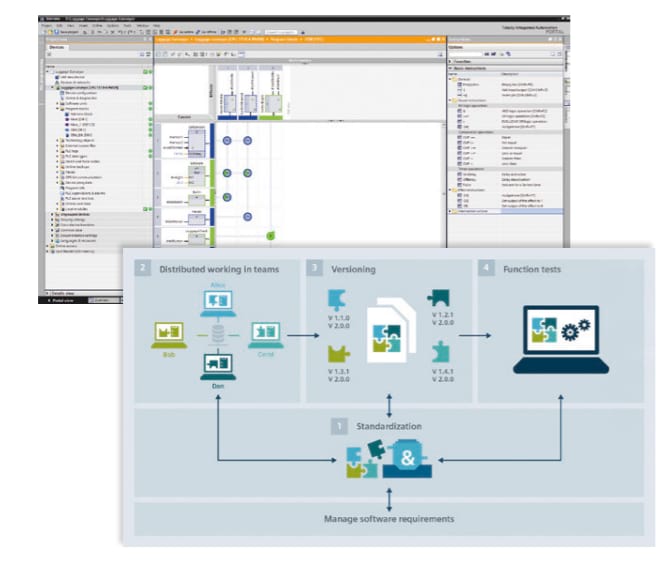

The parallelization of work steps can significantly increase engineering efficiency – provided that workflows are appropriately standardized to ensure that the processes work together smoothly and flawlessly.

TIA Portal provides users with a continuous engineering workflow and offers end-to-end standardization of automation through TIA Portal libraries that store tested modules for its user’s programs. TIA Portal also enables fully integrated engineering workflows based on the model of Continuous Integration, in which developers work as a coordinated team on automation projects.

Efficient engineering also means designing applications instead of programming them. Two new control program editors have been added to TIA Portal V17 for graphical configuration. The CFC Editor for Simatic S7-1500 can be used to interconnect function blocks as a continuous function chart (CFC) and therefore easily configure a signal flow diagram.

This is especially valuable for users who already use CFCs in other projects and can now use the familiar

program structure in TIA Portal as well. Developers can also create functions as a cause-and-effect matrix (CEM) by simply interconnecting ready-made logic modules in the CEM Editor for Simatic S7-1500 and S7-1200.

Using a matrix, developers can configure the dependencies between the modules according to the principle of cause and effect. This type of configuration is especially straightforward thanks to the graphical user interface. It’s also very useful for troubleshooting logical connections between machine states, because relationships between modules are displayed at a glance.

Highlights TIA Portal V17

◾ Standardization with more flexible library concepts

◾ Collaborative work on projects with the project server and multiusers

◾ Increased software quality with TIA Portal Test Suite

◾ New functions for user management

◾ Centralized reporting and diagnostic concepts with OPC UA Alarms and Conditions

◾ Creating simple web-based visualization solutions with Unified View of Things

Users can currently test all the functions of TIA Portal in the cloud free of charge for 21 days. Subscription licensing models for TIA Portal will be available in the future, both in the cloud and with local installation. For even more flexible use in automation projects, TIA Portal Cloud will be offered with TIA Portal V17 for the first time as a subscription model for commercial use.

Siemens TIA Portal V17 – Highlights & Download

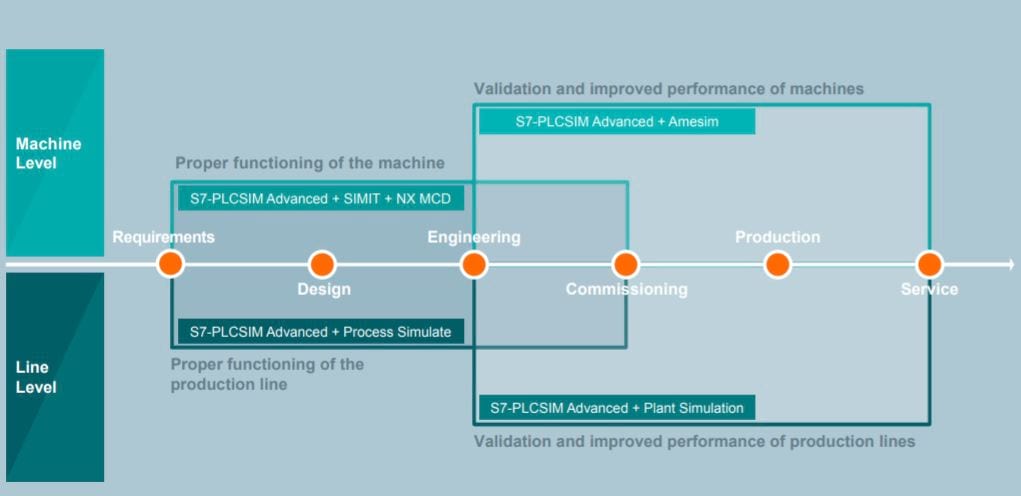

Simulation and virtual commissioning with TIA Portal

The virtual commissioning of machines and plants helps save valuable time during commissioning on-site. By simulating machine and plant behav ior with a digital twin, that same twin can be used across the entire lifecycle of a machine or plant – right up to customer acquisition, or as a realistic model for the virtual showroom.

When production machines are being developed, the simulation of automation, electrical, and mechanical systems can be used to parallelize the design and engineering processes and test them in advance in a digital development environment. A corresponding model can also be used to verify entire production lines prior to physical commissioning. By eliminating the time-consuming process of coordinating individual components, the line can be put into operation faster

A digital twin can also be used to map logistics and material flows: for example, to design conveyor lines and to identify the optimal operating parameters for the conveyor technology. Simulation also helps boost the productivity of machines and plants in operation. A model can be used to determine whether motors and other components contain sufficient reserves for improved performance, whether a higher load will result in vibration, and whether the automation response times are sufficient.

A coordinated portfolio of modeling tools and powerful automation hardware is the foundation for all these applications. From the virtual PLC and the modeling of mechatronic and mechanical components to solutions for modeling physical parameters, users can develop a digital twin to meet their needs in their TIA Portal project – and optimize their processes as a result.