TWK will be attending this year’s Automate Show from May 6th to 9th. The event, which takes place in Chicago, Illinois, offers the safety specialist an exceptional platform to present the latest solutions in safety sensor technology to a global audience of industry professionals.

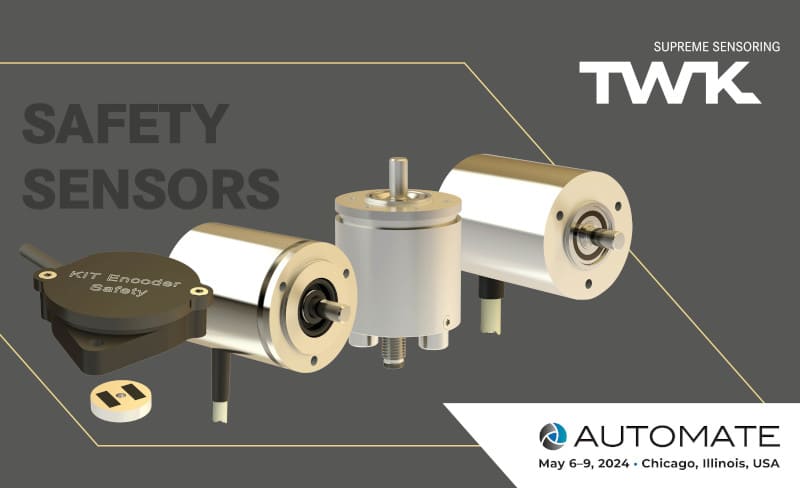

At a time when automation is increasing in all areas of industry, safety has top priority. TWK contributes to safe automation with advanced sensor technologies. The product portfolio includes encoders, inclinometers and vibration sensors that have been specially developed to meet the requirements of modern automation and production technology. The term “safety” is associated with various requirements that must be met. This includes certifications such as SIL2 / SIL3 and PLd / PLe level according to IEC 61508 and ISO 13849-1 or devices with EX protection Zone 1 and 2 according to ATEX / IECEx. Besides, devices with UL® approval according to UL 61010-1, those with ASIL-D according to ISO 26262 and others with E1 approval from the German Federal Motor Transport Authority are available. The safety sensors are also extremely compact and lightweight, with a diameter of just 38 mm for single-turn versions and 42 mm for multi-turn versions.

TWK is excellent in providing flexible and customizable sensor solutions that can be integrated easily into a wide range of system architectures. With interfaces such as PROFIsafe via PROFINET, Failsafe over EtherCAT (FSoE), CANopen Safety or incremental options, they offer a wide range of configuration options to meet the specific needs of their customers and develop customized solutions. Additional interfaces can also be implemented and offered on request, including J1939 Safety, BISS Safety or LoRaWAN. With speeds of up to 15,000 rpm and a position resolution of 16 bits / 360° as well as a speed signal of 16 bits and degrees of protection up to IP69K, the sometimes fully redundant encoders are used, for example, in the steering angle and speed detection of a drive system. They are attached directly to the wheel of driverless transport systems, for example, or to the motor with a reduction gear. For the latter, the special SIL2 slewing ring function is available for multiturn encoders if required. Housing materials of aluminium, stainless steel 1.4404 or magnetically shielded stainless steel ensure maximum environmental resistance and operational safety.

The portfolio also includes draw-wire sensors that are connected directly to a rotary encoder, ideal for measuring lifting processes at forks or booms. These sensors can convert vertical movements into rotary ones, and, depending on the type, measure up to 30 metres. To prevent vehicles from tipping over, inclination sensors certified to SIL2 / PLd have been added to the portfolio. These are also equipped with gyroscope sensors and can supply not only the corrected tilt angle but also speed data and raw values from six axes via PROFIsafe or CANopen Safety. Accelerometer data are particularly useful for condition monitoring of the vehicles (e.g. by detecting vibrations) or for use in control tasks. Some of these devices can also be equipped with safety switches to monitor limit values, and thus safety during operation is increased.

At the Automate Show, TWK can be found at stand 3786 in the South Building. The team of experts will be on hand to discuss individual requirements and demonstrate how safety sensors can help achieve safety and efficiency goals.