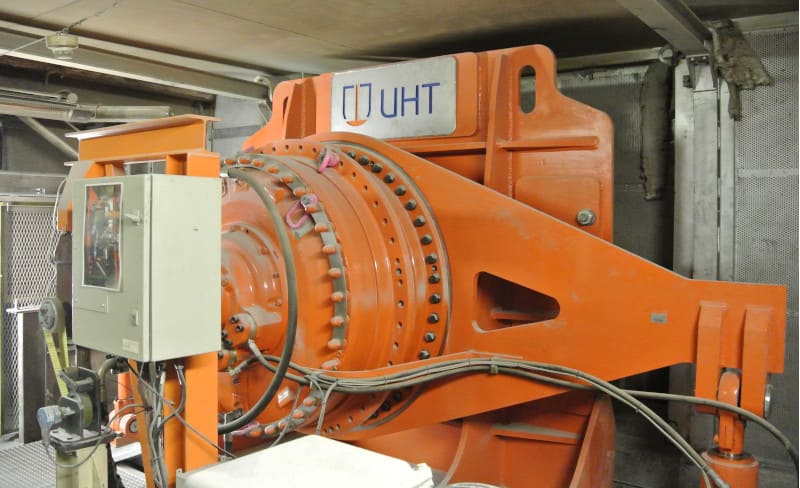

For the refining of steel, stainless steel and ferro alloys, the Swedish company Uvån Hagfors Teknologi (UHT) AB offers, among other things, a special converter process. This places special demands on the drive technology, because it not only has to be particularly robust and reliable, but the process must also be able to be precisely controlled with it. UHT uses Hägglunds direct drives for this purpose. Together with UHT’s steel management system, this provides customers with an optimally coordinated system solution for the refining process.

The Swedish company Uvån Hagfors Teknologi (UHT) AB is a global supplier of metallurgical processes for the production of steel and iron alloys. An important part of this is the converter refining. In this process, oxygen and inert gases are blown into the molten metal. The resulting chemical reactions remove carbon and impurities from the metal. The process is used in the production of ferrous alloys and stainless steel and requires special converter vessels that rotate both during charging, sampling procedures and tapping.

UHT had initially specified electromechanical drives for the converters. “When you blow gas into molten materials, it creates a lot of vibration and very high torque,” Joakim Lundström, project manager at UHT, summarises. “That vibration put a lot of stress on the electromechanical drives.” This increases the effort and costs for maintenance and servicing of the gears. Hydraulic drives, on the other hand, can even prevent wear: “A Hägglunds drive absorbs the vibrations, it reduces strain on both the converter and the concrete foundation that supports it,” summarizes Lundström. “The drives provide full torque from zero, which is very important. It means our converters can tilt more quickly and accurately, because they have full power from the very first second. That’s a clear advantage for customers who want to shorten their process times and minimize metal carry over during refining.”

With UTCAS, UHT also offers its own steel management system. It takes over all calculations and controls exactly when the gas mix is changed or material is added. These are optimal conditions for the production of stainless steel and ferroalloys.