Once the preserve of high-volume operations at automotive plants, we’re today finding that robots are infiltrating all sectors of the commercial world. Even beyond traditional manufacturing, inspection and packaging operations, we see robots fulfilling tasks that extend from mining and space exploration, through to surgery and laboratory research, and even fruit picking. With such a vast repertoire of applications, the robots of today need one principal attribute: flexibility. Much of this flexibility comes courtesy of the end-of-arm tooling (gripper), which means there are many factors to bear in mind when selecting a gripper technology supplier, not least breadth of portfolio, proven customisation capabilities and high levels of customer support.

Autor: Marcus Mazetti, Global Account Manager, SMC Sweden

We all know that automobile factories have been running on automation for many years. This sector also remains a key driver of robotics sales worldwide. Aside from welding and painting, the automotive industry deploys robots for tasks that include assembly, trimming, cutting, part transfer and machine tending, to list but a few.

Taking note of the progress made by automotive plants is a growing selection of other industries, including food, beverage, life science and agriculture, all of which are increasing their robot uptake in order to drive up productivity, efficiency, staff safety, product quality and revenue. In short, there is additional focus on making production lines more flexible and better able to efficiently achieve high-mix, lower-volume production in response to constantly evolving customer demands.

New industries drive demand

According to a McKinsey report, 88% of businesses worldwide plan to introduce robotic automation into their infrastructure. With so many new industries driving sales, Mordor Intelligence reports that the global robotics market could reach $74.1 billion by 2026 (up from 27.73 billion in 2020), registering a CAGR of 17.45%. However, while the future looks bright for those in the robotics arena, we know from experience that there are certain prerequisites which underline success in sectors other than automotive.

Whereas robots in the high-volume automotive arena typically perform a single task, flexibility is the key word for non-automotive robot applications. Here, users assign robots to different tasks that may change regularly. For those of you thinking that programming is an issue in high-mix, low-volume manufacturing environments, think again. Robot OEMs, cobot (collaborative robot) specialists and software companies are today providing solutions that ensure straightforward programming, to the point where even operators with little or no experience can generate motion paths in next to no time.

AI and ML

While we are all aware that robots perform repetitive tasks more efficiently than humans, there’s a new trend here: with AI (artificial intelligence) and ML (machine learning), robots are able to think, learn and draw accurate conclusions without the help of their human colleagues. It’s an exciting prospect for industry across the board, particularly when you consider that robots can support the shift to Industry 4.0/digitalisation, largely because they outperform traditional motion systems in complex tasks.

For instance, while many machines on the shop floor feature full automation, handling tasks from the warehouse to final assembly and packaging are often unautomated due to the inherent complexities involved. Today, however, the latest robotic solutions are assisting continuous flow across the factory, potentially leading to the concept of ‘dark’ or lights-out manufacturing, with no or very few people controlling operations.

Bespoke solutions

With robots set to become a core resource at many types of factory, achieving flexibility is paramount for any tasks that involve handling or servicing. Here, around 50% of applications require finger and/or gripper modifications to suit customer requirements.

For both robot users and manufacturers there are several objectives when it comes to product selection, including price-performance ratio, flexibility, ease of adoption and safety. However, end-of-arm gripper technology is a key factor for tasks such as materials handling, packaging, machine tending, assembly, quality control and surface finishing.

Here at SMC we offer a full range of gripper solutions, including pneumatic, electrical, magnetic and vacuum, ensuring adaptability to all gripping needs. We can also supply FRL units, tubing, valves and serial communication, either using wireless or traditional wired technology, thus creating a turnkey solution for new robot installations or retrofit projects.

We help robotics engineers tap into ‘languages’ with which they are likely unfamiliar, such as pneumatics, by helping to translate or interpret the requirements of air-driven motion control and the benefits it can bring. Our expert team can help explain everything from valve island technology and filtration, to air flow and system pressure. Even though SMC offers an extensive series of electric actuators, pneumatics remains our principal language, which is why increasing numbers of robot OEMs and manufacturing plants are requesting our help.

Rapid tool changes

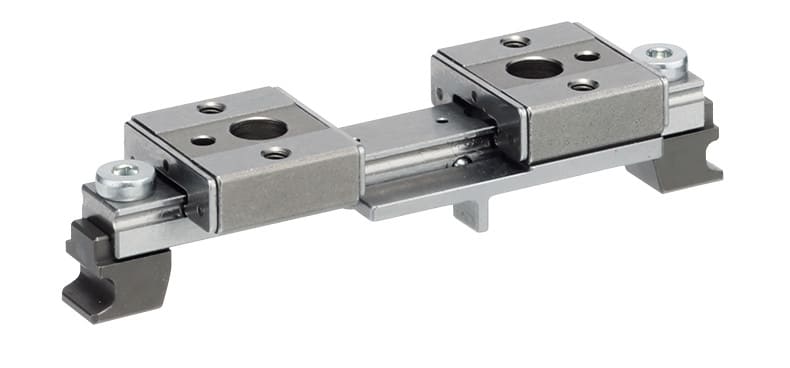

To deliver flexibility, robots frequently need to use multiple different grippers, which is why fast and reliable tool-change technology is paramount. However, many solutions are expensive and carry some risk due to complex air/signal connections. For this reason, our team of design engineers here at SMC developed the MHF2-X7076A, a modular, low-profile air gripper with finger-change function. This automatic tool-change device for robots means users simply replace the end of the gripper (the finger) without any risk. The wiring and piping are bundled together in the body of the air gripper (robot side) to improve electrical contact during tool changes and reduce air leakage.

As a further market differentiator, we offer wireless communication with the gripper to eliminate any risk of communication loss and stoppages. Our EX600-W wireless system means less cables and connectors, reduced installation and maintenance, and fewer breakages and disconnections to deliver totally reliable, noise-resistant communication. Robot users are increasingly adopting our fast-response EX600-W wireless system improve their OEE (overall equipment effectiveness), a key metric for any production or process operations.

Moving forward, our R&D team is working constantly on system modularity, driving up the speed of gripper changes and reducing the risk of stoppages. Your productivity and uptime are our top priorities. Around 50% of all robot grippers we currently produce are custom builds, highlighting our credibility as a capable and proven technology partner.